Container for storing semiconductor device

a technology for semiconductor devices and containers, applied in the field of containers, can solve the problems of high integrated density semiconductor devices, high temperature of semiconductor devices, and high temperature of semiconductor devices, and achieve the effects of preventing contamination, reducing friction between fasteners and drivers, and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]For solving the problem of friction occurred between each component of the fastening member of the container that cause contamination of semiconductor stored in the container, a container for storing semiconductor devices of the present invention is provided.

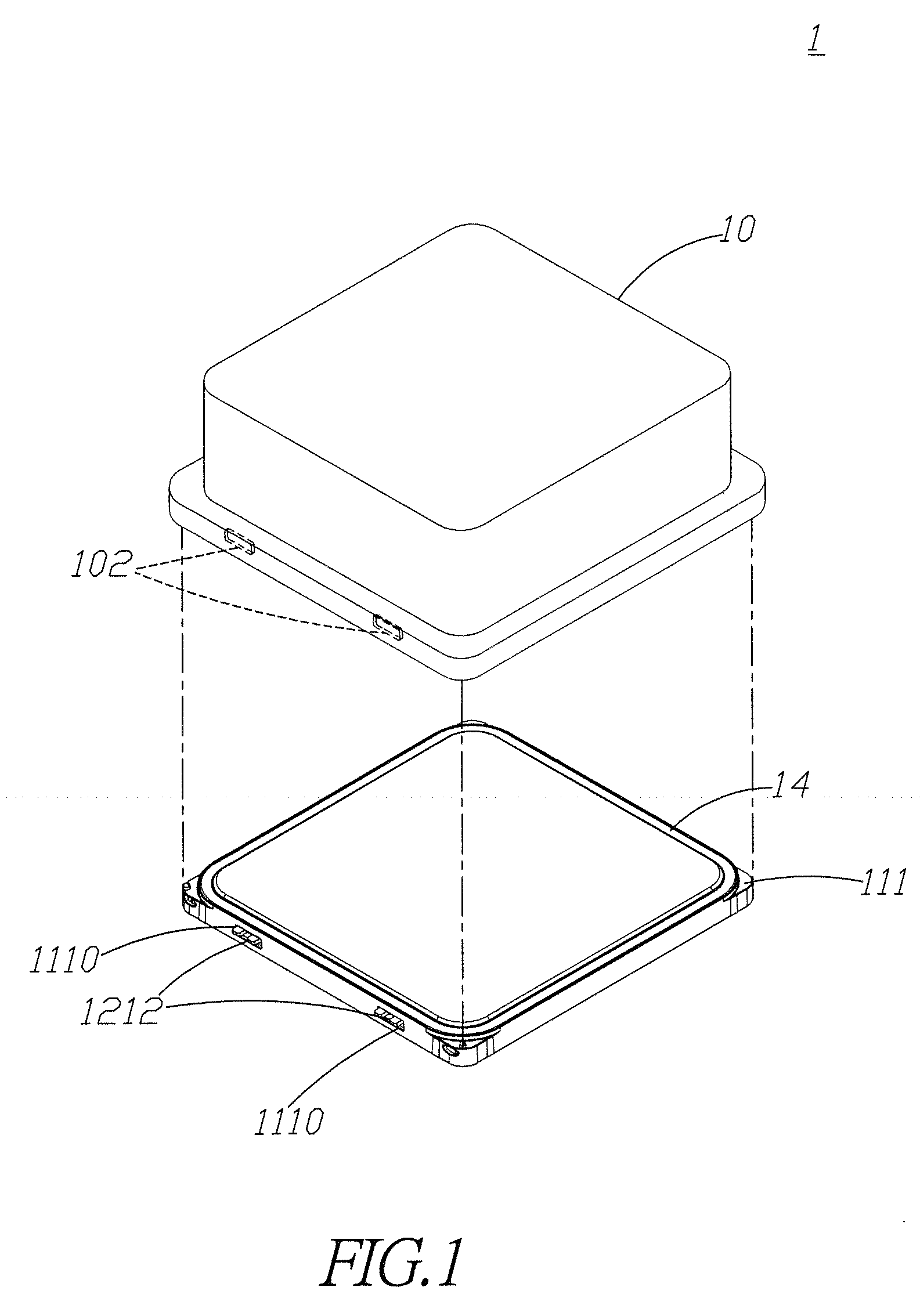

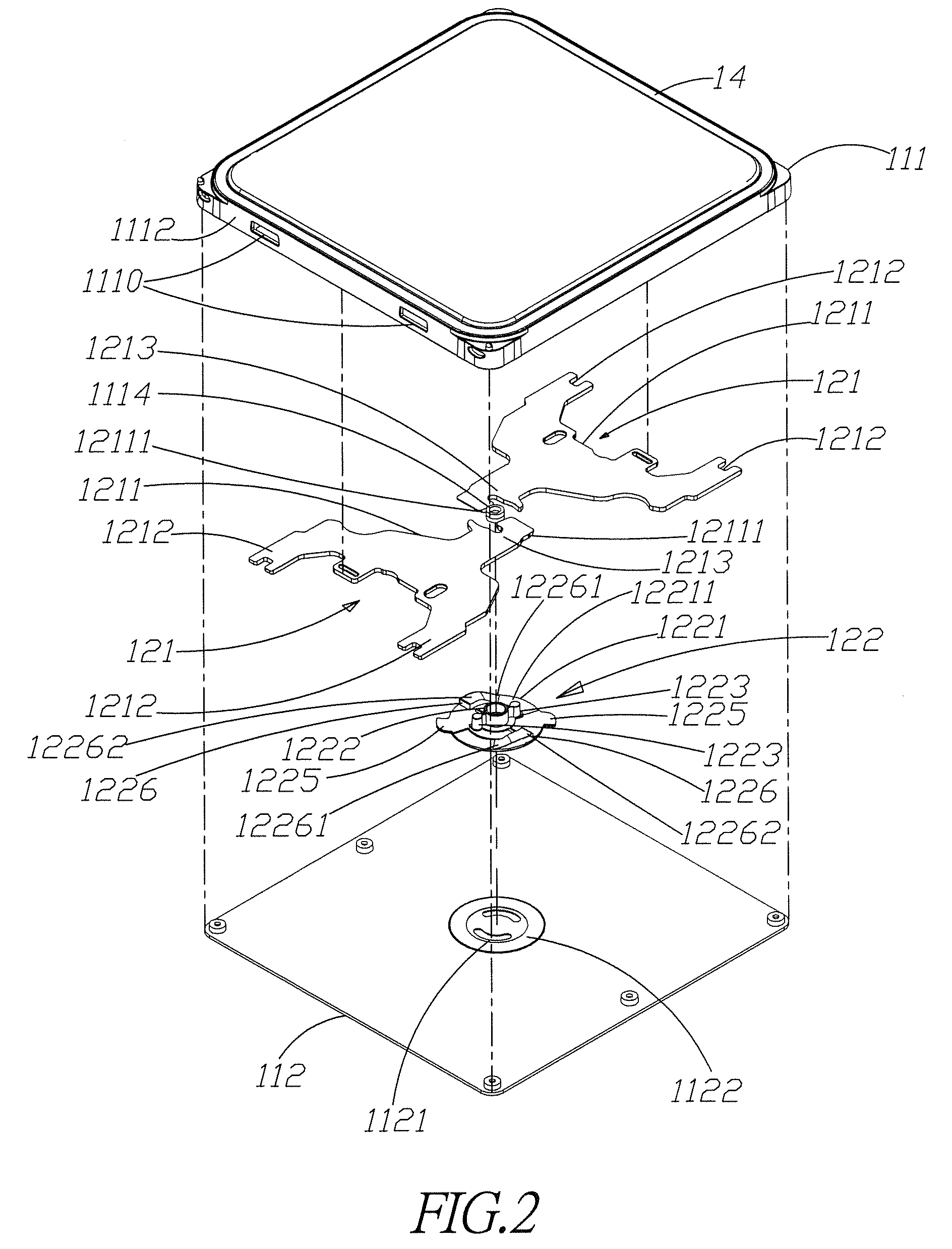

[0022]Refer to FIG. 1, FIG. 2 and FIG. 3, a container for storing semiconductor devices 1 includes a cover 10, a receiving body, and a seal plate 112. At least one semiconductor device is loaded on an outer surface of the receiving body 111 and the cover 10 is disposed over the outer surface of the receiving body 111. The receiving body 111 is mounted with a fastening member therein and the seal plate 112 is against the fastening member for fixing the fastening member in the receiving body 111. The cover 10 is fixed on the receiving body 111 by the fastening member. Thus the container 1 is airtight and is free from external contaminants. Therefore the semiconductor device (such as photomask, wafer or others) will not be po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com