Circuit Integrity Detection System for Detecting The Integrity of A Sensing Wire in Electrically Heated Textiles

a sensing wire and circuit integrity technology, applied in the direction of heat measurement, instruments, testing circuits, etc., can solve the problems of inability of the controller to detect hot spots, inability to work as a continuous “broken sensing wire” detector, and heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

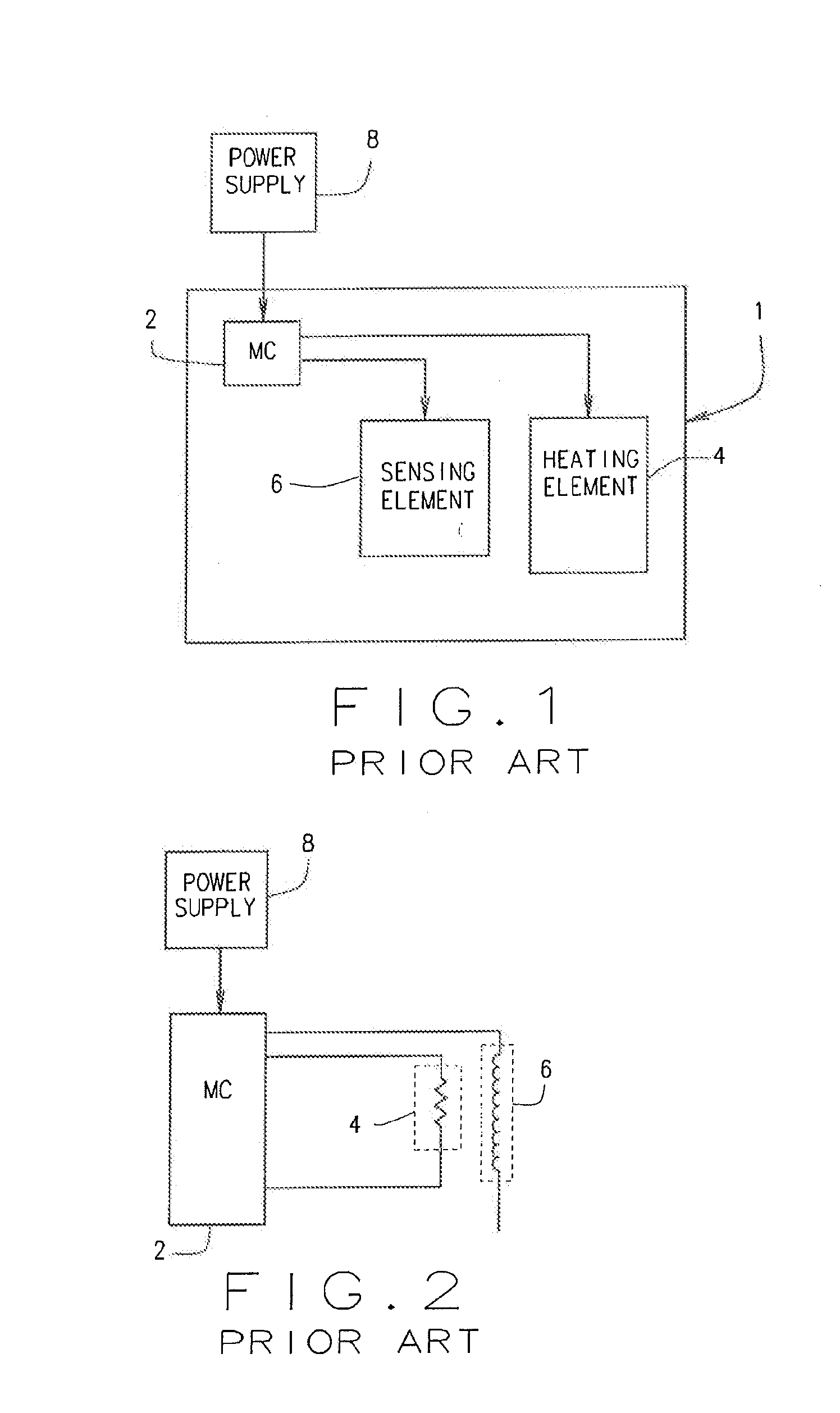

[0023]Referring now to the drawings and, more particularly, to FIG. 1, a block diagram of a prior art electrically heating textile, such as a heating pad 1 is shown. Heating pad I includes a heating pad controller 2, which may include a microprocessor or microcontroller, for controlling the operation of the heating pad 1. Microcontroller 2 is in electrical communication with a heating element 4, and supplies power to the heating element 4 to heat the heating pad 1. Alternatively, microcontroller 2 may be located outside of the heating pad. Microcontroller 2 is also in electrical communication with sensing element 6. Sensing element 6 is a safety feature designed to detect hot spots in heating pad 1. Upon detection of a hot spot, microcontroller 2 generally deactivates or reduces power to heating element 4 until the hot spot is no longer present. A power supply 8 is generally electrically connected to microcontroller 2 to provide electrical power thereto. Power supply 8 is generally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com