Prefabricated Cladding Assembly

a cladding assembly and prefabricated technology, applied in the field of cladding systems, can solve the problems of presenting a number of problems in the fabrication of cladding systems using bonding rather than screw fixing, and achieve the effects of less on-site adjustments, improved accuracy and consistency of cladding assembly construction, and consistent bond formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

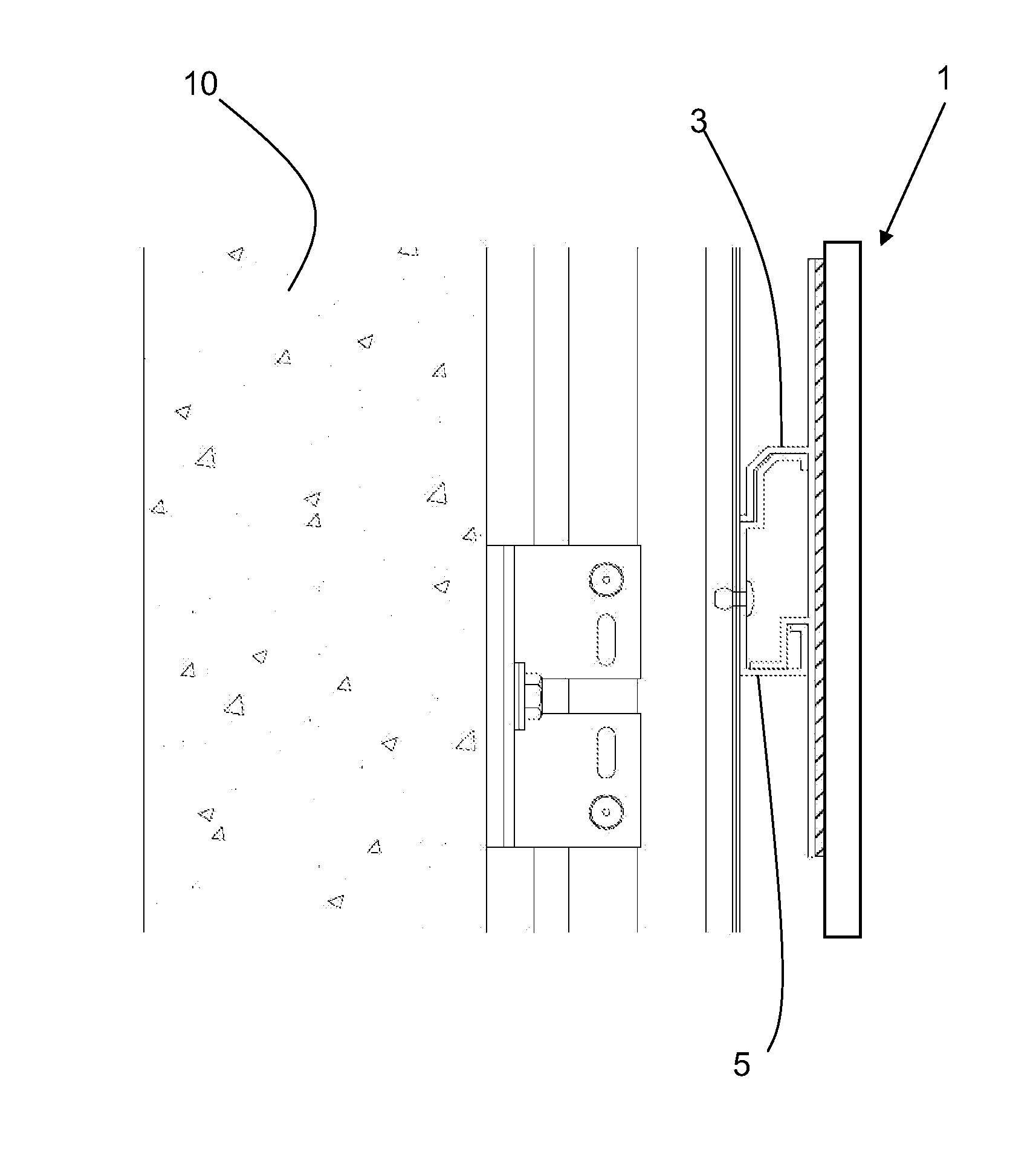

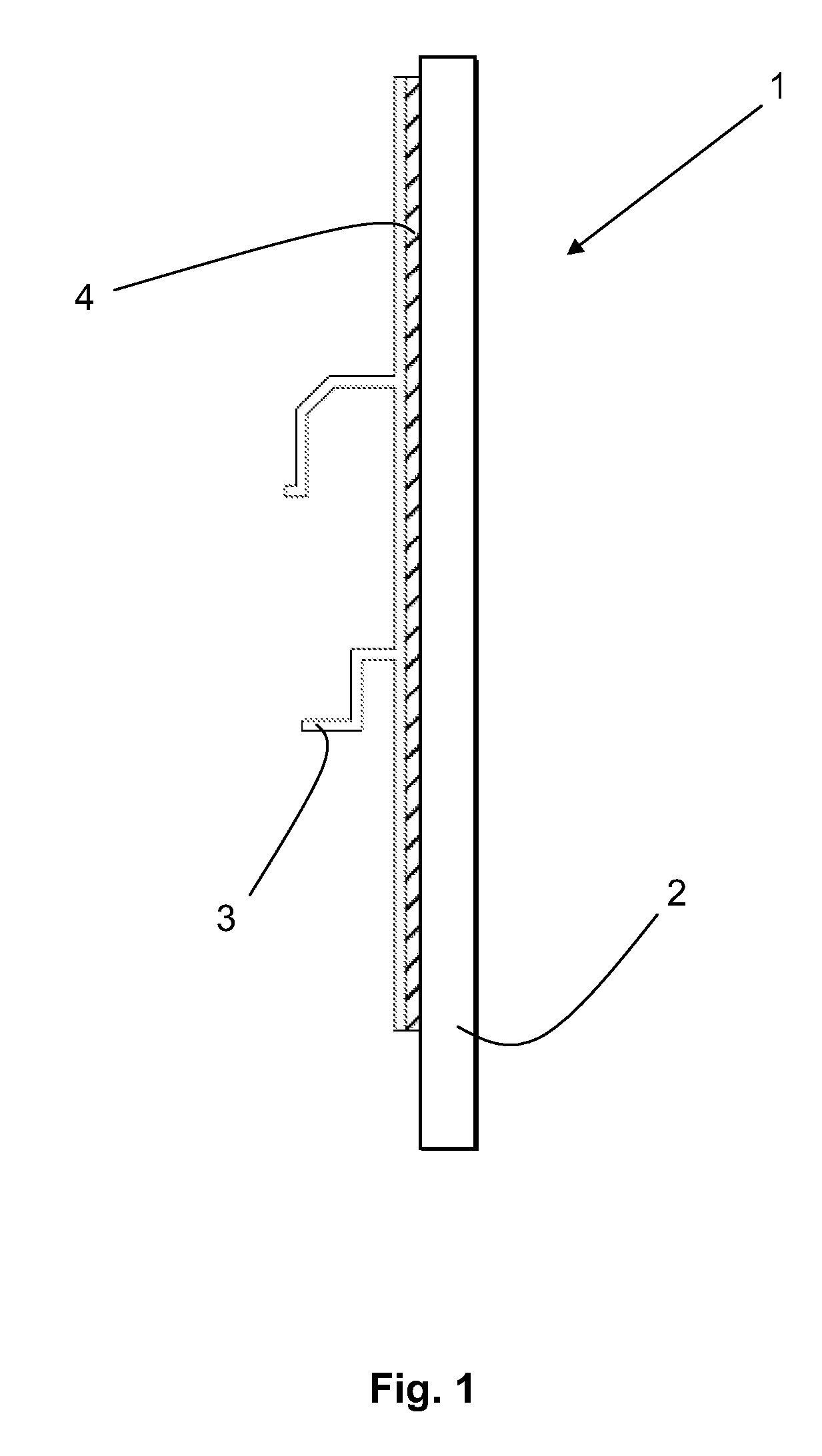

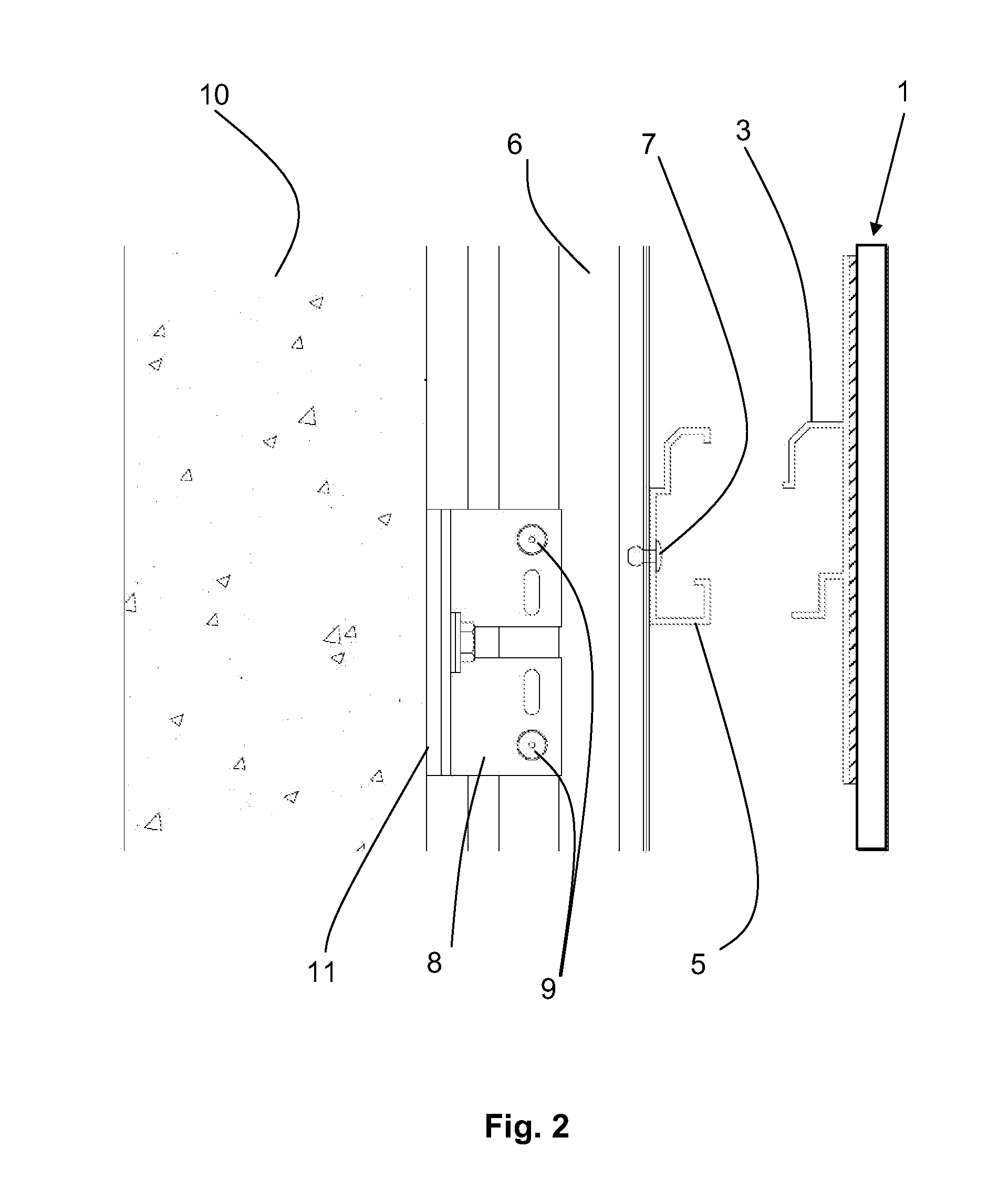

[0021]A preferred embodiment of the prefabricated cladding system of the present invention essentially comprises a prefabricated cladding panel 1. The panel 1 is manufactured off-site by using adhesive, possibly in the form of adhesive tape 4, to securely attach a piece of panel 2 to a mounting bracket 3.

[0022]As will be appreciated from the figures the mounting bracket 3, which is preferably formed by the extrusion moulding of a suitable material (such as aluminium) is secured to the back of the panel 2. It is envisaged that a wide range of suitable materials exist for the panel 2 and the actual material used would vary depending upon what finished appearance is required.

[0023]Although the cladding panel 1 shown in FIG. 1 only has a single mounting bracket 3 it is appreciated than multiple brackets might be secured to the back of the larger panel to better support the weight of the panel and any wind loading the panel may be exposed to.

[0024]As will be appreciated from FIG. 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com