Indicator member, indicator unit and indicator instrument

a technology of indicator parts and indicators, applied in the field of indicators, can solve the problems of increasing the manufacturing cost of indicators, increasing the number of components, increasing the man-hour for assembly, etc., and achieve the effects of preventing non-uniform brightness, and reducing the risk of affecting the quality of indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0242](1.8)

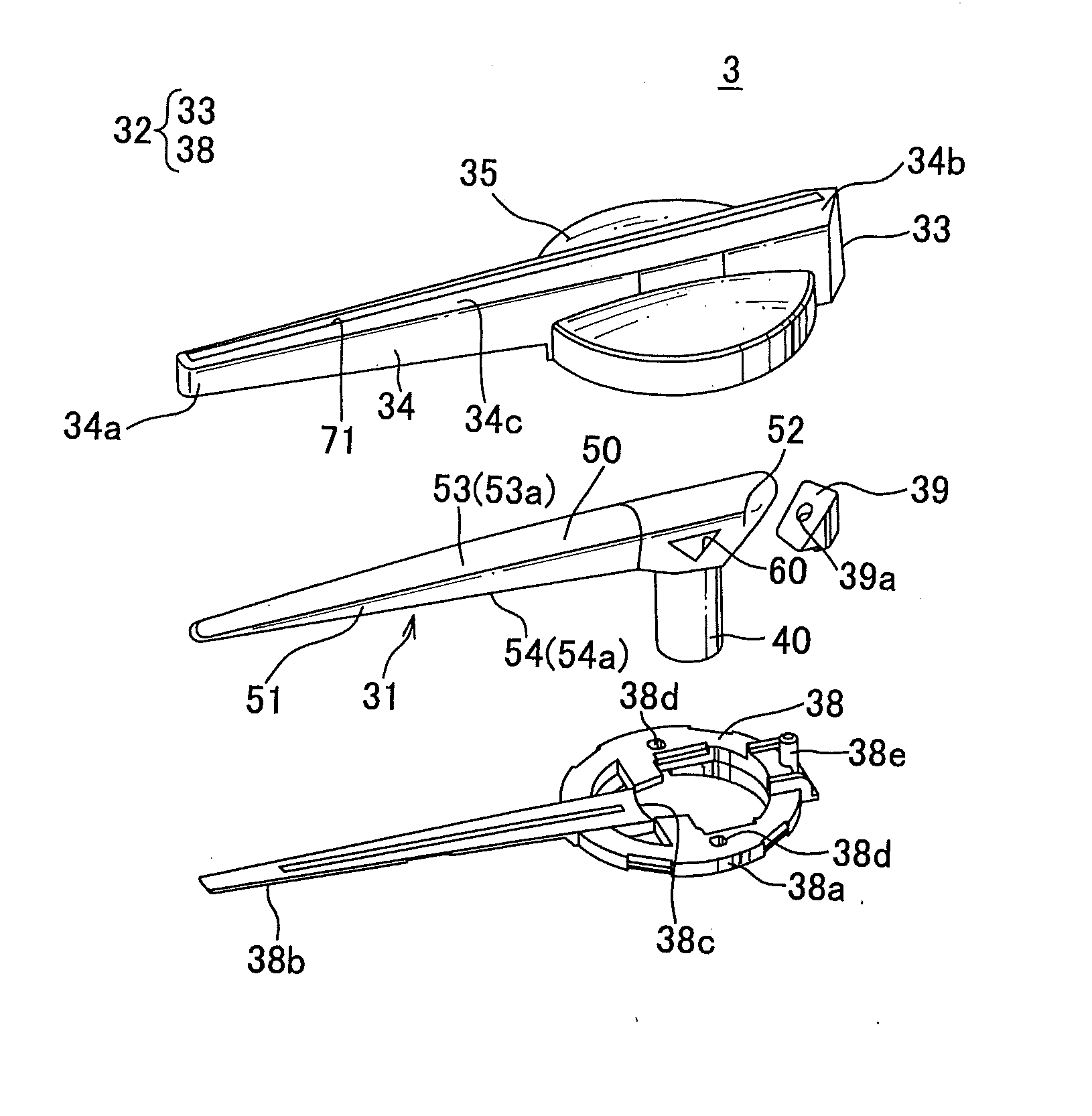

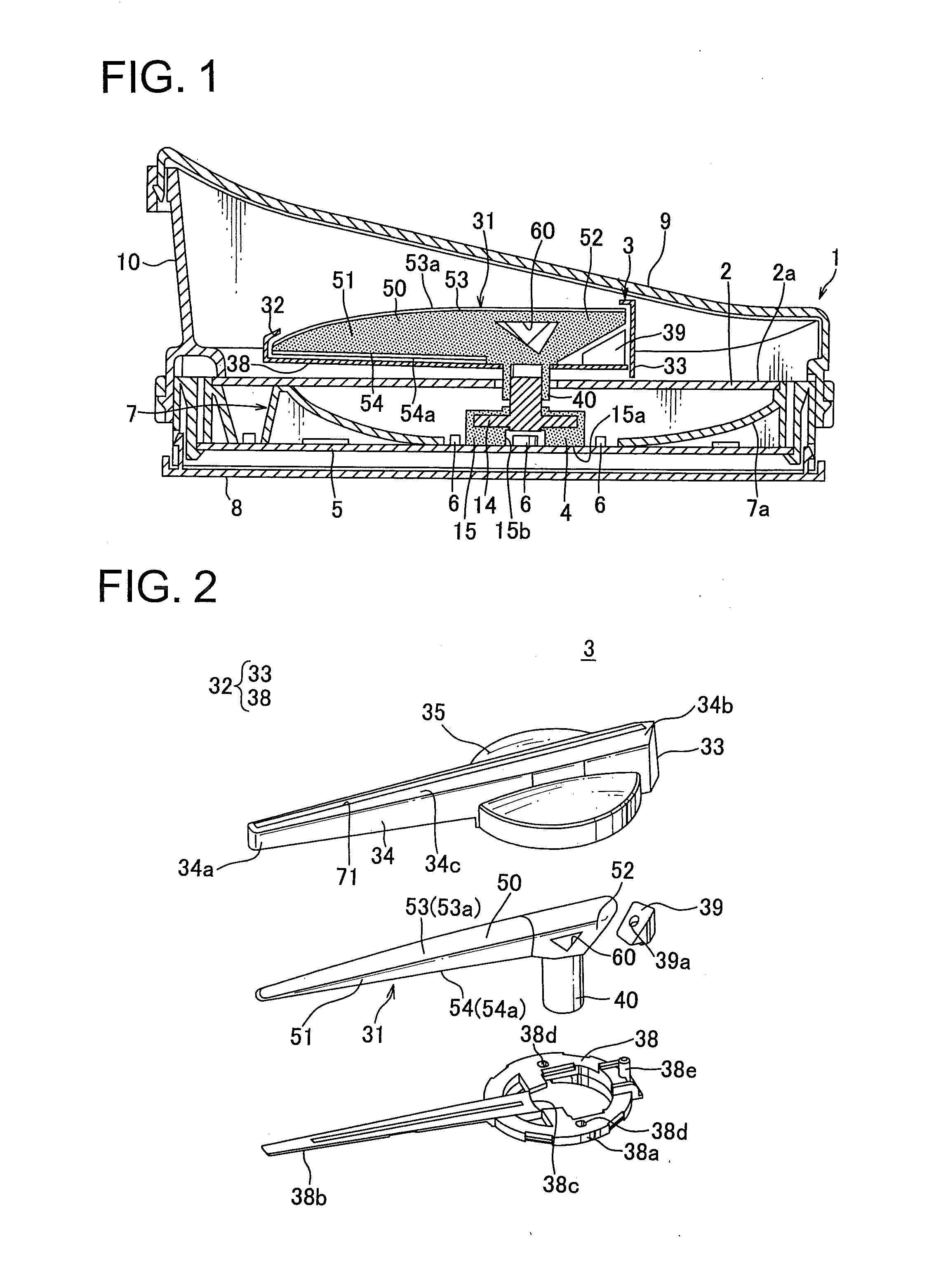

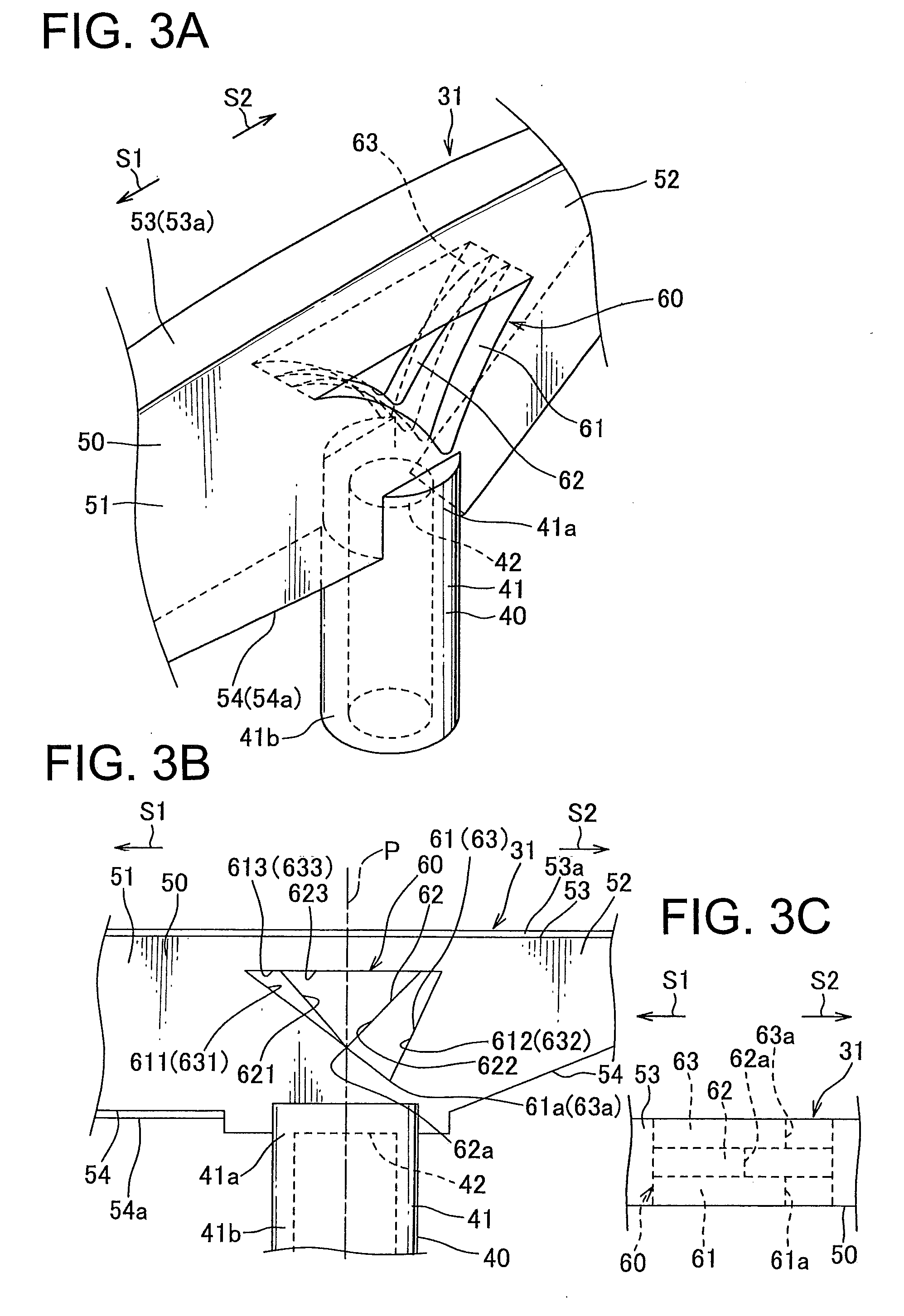

In the following, a vehicle display device as one embodiment of an indicator instrument according to the present invention is explained in reference to FIGS. 1 through 4B.

[0243]In FIG. 1, a vehicle display device 1 is a speed meter which displays a vehicle speed, for example. The vehicle display device 1 includes a dial plate 2 having a surface 2a (i.e. a surface which is visible by a viewer) provided with indexes such as scale marks and numbers, letters or symbols, a light-emitting indicator (hereinafter called an indicator) 3 as an indicator unit positioned on the surface 2a of the dial plate 2, a drive device 4 having an indicator shaft 14 including a distal end at which the indicator 3 is attached, a circuit board 5 including a circuit pattern, an electronic component and such and including the drive device 4 fixed to the circuit board 5, a plurality of light sources 6 provided at the circuit board 5, a case 7 having a tapered portion 7a formed from a central portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com