Forward-pressed finger rest for slide-action stock

a slide-action stock and forward-pressed technology, which is applied in the field of manual reciprocation slide-action stock for semi-automatic firearms, can solve the problems of many safety and accuracy issues of belt loop method, operator's skin burns or possibly pinches, and operator's sleeve or skin burns, etc., to achieve the effect of increasing the firing rate of a semi-automatic firearm without compromising the safety of the user or the accuracy of the firearm, and not pron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

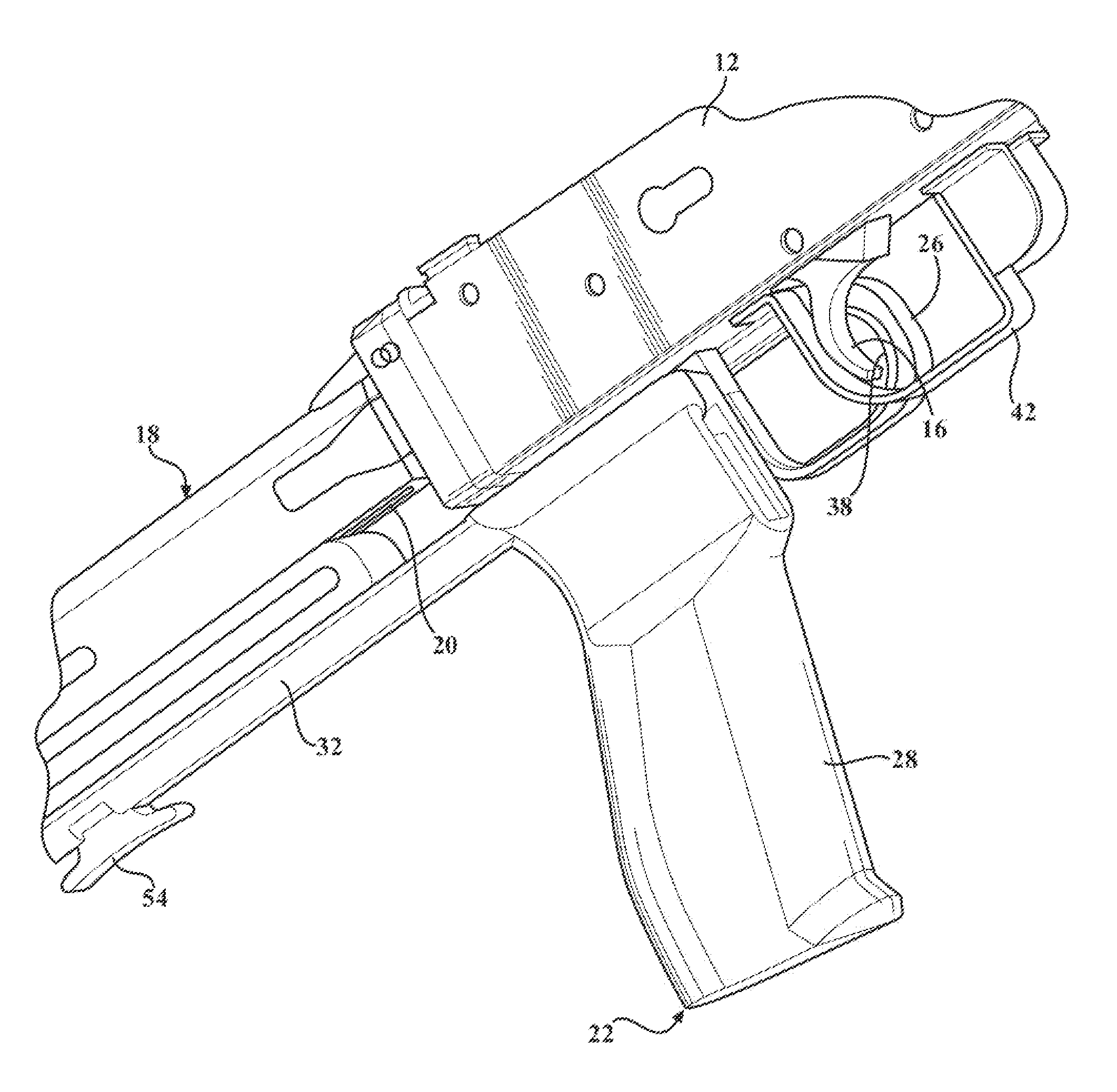

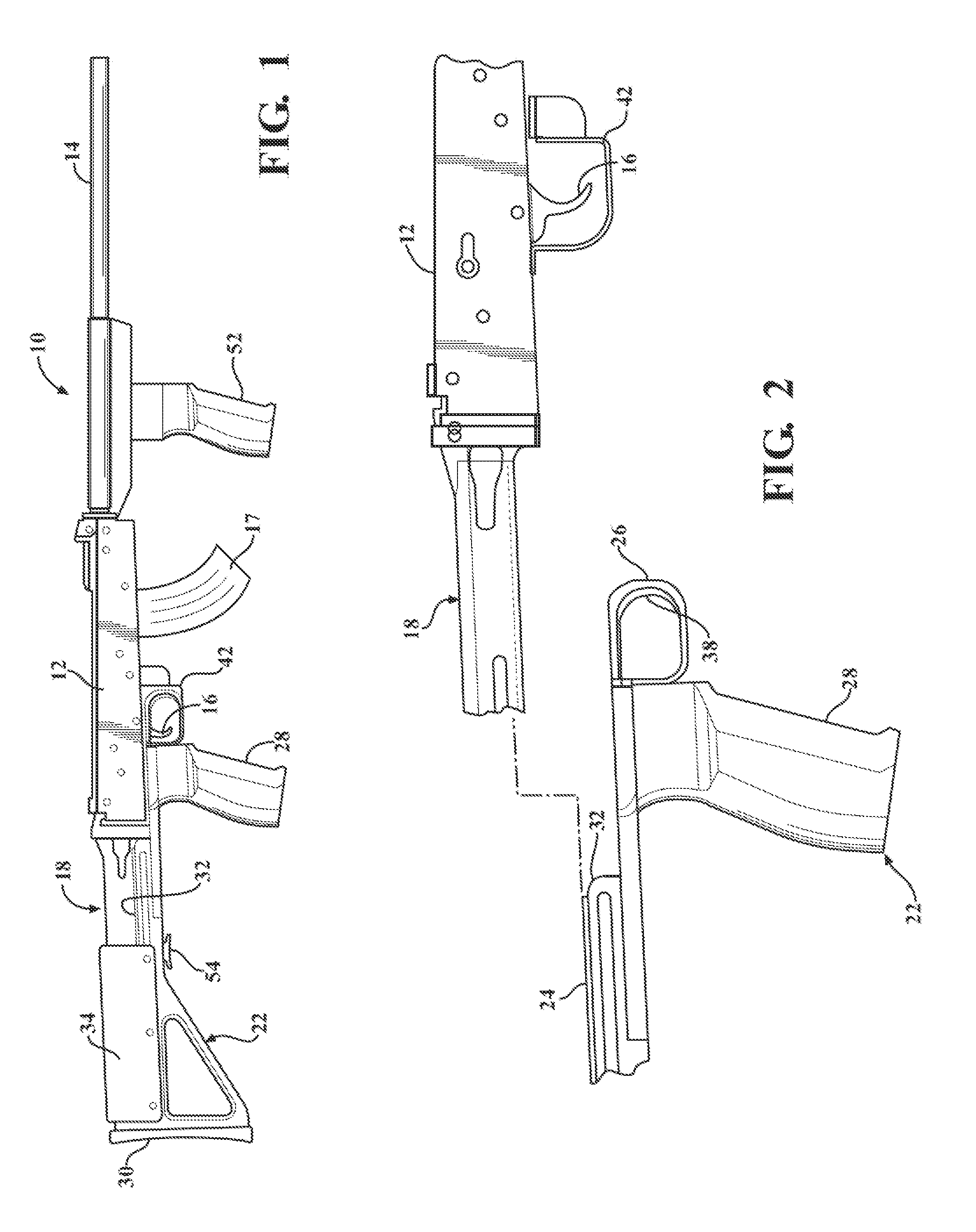

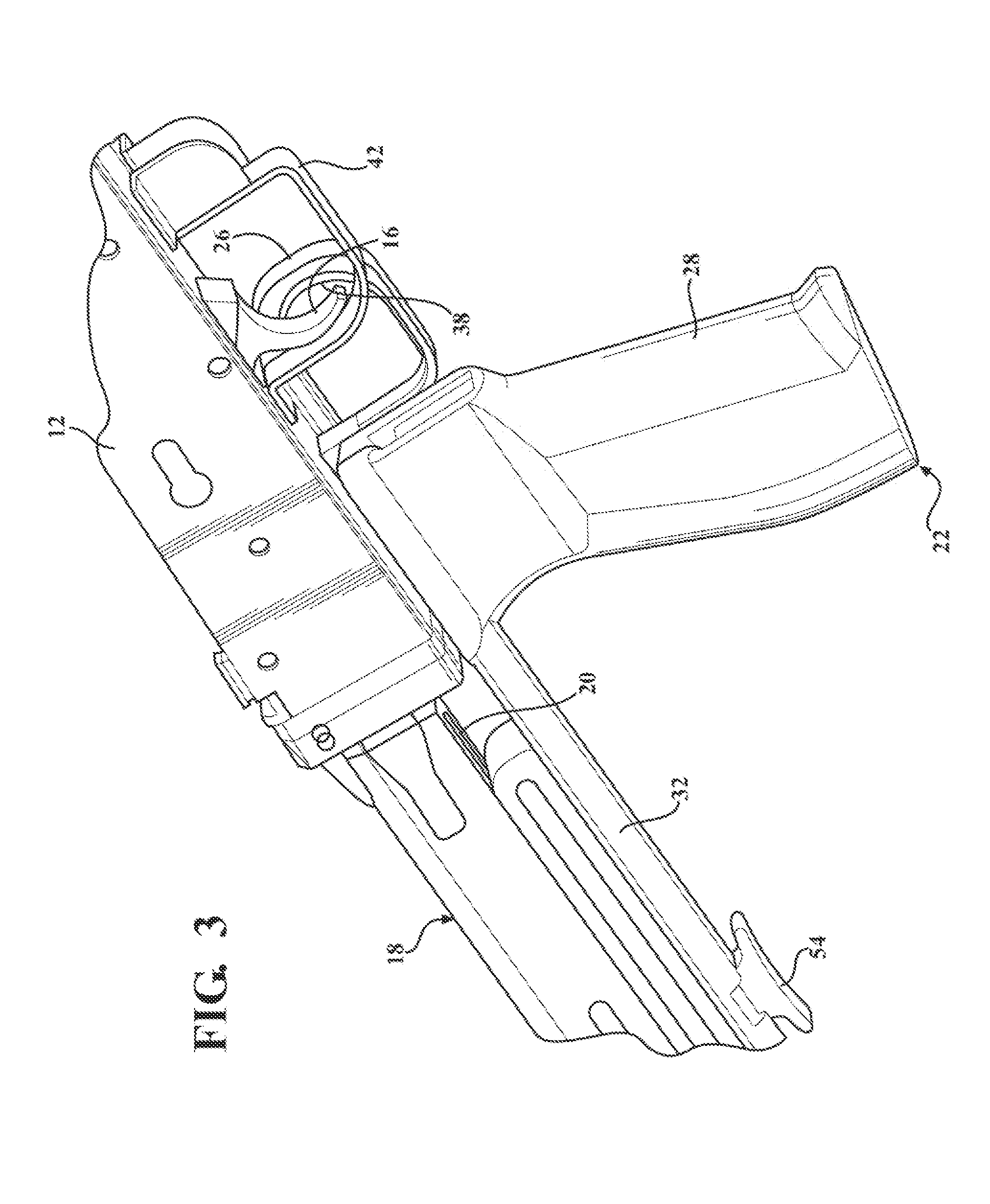

[0023]Referring to the figures wherein like numerals indicate like or corresponding parts throughout the several views, a semi-automatic firearm according to one exemplary embodiment of this invention is generally shown at 10 in FIG. 1. In the illustrated examples, the firearm 10 is depicted as a rifle or long gun; however the principles of this invention may be applied with success to hand guns and pistols. Therefore, those of skill in the art should appreciate that the term firearm as used throughout this patent application is applicable to all forms of semi-automatic projectile-firing devices.

[0024]The firearm 10 includes a receiver 12 and a barrel 14 and a trigger 16 operatively connected together as a firing unit. Ammunition (not shown) fed into the receiver 12 (such as through a magazine 17 or a belt system) is presented into a firing chamber (not shown) at the base of the barrel 14. A firing pin struck by a hammer (neither of which are shown) ignites a round of ammunition in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com