Lubricating oil composition

a technology of lubricating oil and composition, which is applied in the direction of lubricant composition, petroleum industry, etc., can solve the problems of oil not being able to meet the recent further fuel saving demand and not being able to generate sufficient hydraulic pressure, so as to reduce the resistance to lubrication and enhance the fuel efficiency of the automobile

Inactive Publication Date: 2014-01-09

JX NIPPON OIL & ENERGY CORP

View PDF1 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

The present invention relates to a lubricating oil composition that can improve engine fuel efficiency. The oil composition features a specific lubricating base oil that has a low resistance to lubrication, making it suitable for use in automobile transmissions. The base oil can be either mineral or synthetic, with a specific viscosity range. The composition also includes specific additives that further improve fuel efficiency. Overall, this lubricating oil can improve engine performance by reducing friction and increasing fuel efficiency.

Problems solved by technology

However, as described above, the lubricating oil used in these transmissions is also used as a medium for a hydraulic control system and thus would have problems that it would fail to generate sufficient hydraulic pressure due to the leakage from the oil pump or control valve if it is excessively reduced in viscosity.

However, the oil has been unable to meet the recent further fuel saving demand.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

examples

[0113]The present invention will be described more specifically with reference to the following Examples and Comparative Examples but not limited thereto.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Login to View More

Abstract

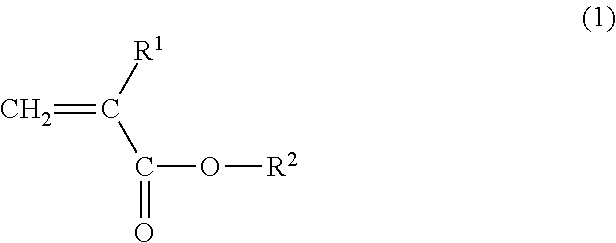

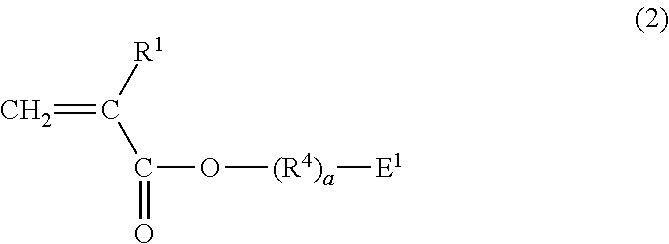

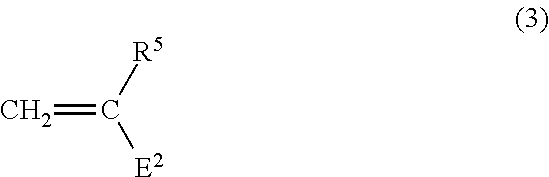

A lubricating oil composition which exceeds the fuel saving performance of a conventional low viscosity lubricating oil composition, contains (A) a lubricating base oil having a % CA of 2 or less, adjusted to a 100° C. kinematic viscosity of 1.5 to 4.5 mm2 / s and (B) a viscosity index improver including (B1) a poly(meth)acrylate having a weight-average molecular weight of 50,000 or less in an amount of 1 to 10 percent by mass and (B2) a poly(meth)acrylate having a weight-average molecular weight of 100,000 to 250,000 in an amount of 0.1 to 5 percent by mass of the total composition. The composition has a 80° C. high-shear viscosity (Vs: mPa·s) and a 80° C. kinematic viscosity (Vk: mm2 / s) ratio (Vs / Vk) of less than 1, a coefficient of traction of 0.02 or less at 40° C., an average speed of 3.0 m / s, a slip ratio of 10%, and a contact pressure of 0.4 GPa.

Description

TECHNICAL FIELD [0001]The present invention relates to lubricating oil compositions, more specifically to those having an enhanced fuel saving performance, suitable for automobile automatic transmissions, manual transmissions, and continuously variable transmissions.BACKGROUND ART [0002]Recently, energy saving in automobiles and construction or agricultural machinery, i.e., fuel saving has become an urgent need in order to deal with environmental issues such as reduction in carbon dioxide emissions, and units such as engines, transmissions, final reduction gears, compressors, or hydraulic power units have been strongly demanded to contribute to energy saving. Consequently, the lubricating oils used in these units are required to be reduced in stir resistance and frictional resistance more than before.[0003]Reduction of the viscosity of a lubricating oil can be pointed out as an effective energy saving means. For example, an automobile automatic transmission or continuously variable ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M169/04

CPCC10M169/04C10M145/14C10M2209/084C10M169/041C10M2203/1025C10M2223/04C10M2229/02C10N2020/04C10N2020/017C10N2020/02C10N2030/02C10N2010/04C10N2030/06C10N2030/54C10N2030/68C10N2040/045C10N2040/044C10N2040/042C10N2040/04C10N2060/14

Inventor ONUMATA, YASUSHIABE, NORIKO

Owner JX NIPPON OIL & ENERGY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com