Touch-sensing panel and touch-sensing liquid crystal display panel using the same

a touch sensor and liquid crystal display panel technology, applied in the direction of instruments, computing, electric digital data processing, etc., can solve the problems of limited thickness and weight achieve the reduction of the manufacturing cost the thickness of the touch sensor liquid crystal display panel can be accordingly reduced, and the effect of reducing the manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]To provide a better understanding of the present invention, exemplary embodiments will be detailed as follows. The exemplary embodiments of the present invention are illustrated in the accompanying drawings with numbered elements to elaborate the contents and effects to be achieved.

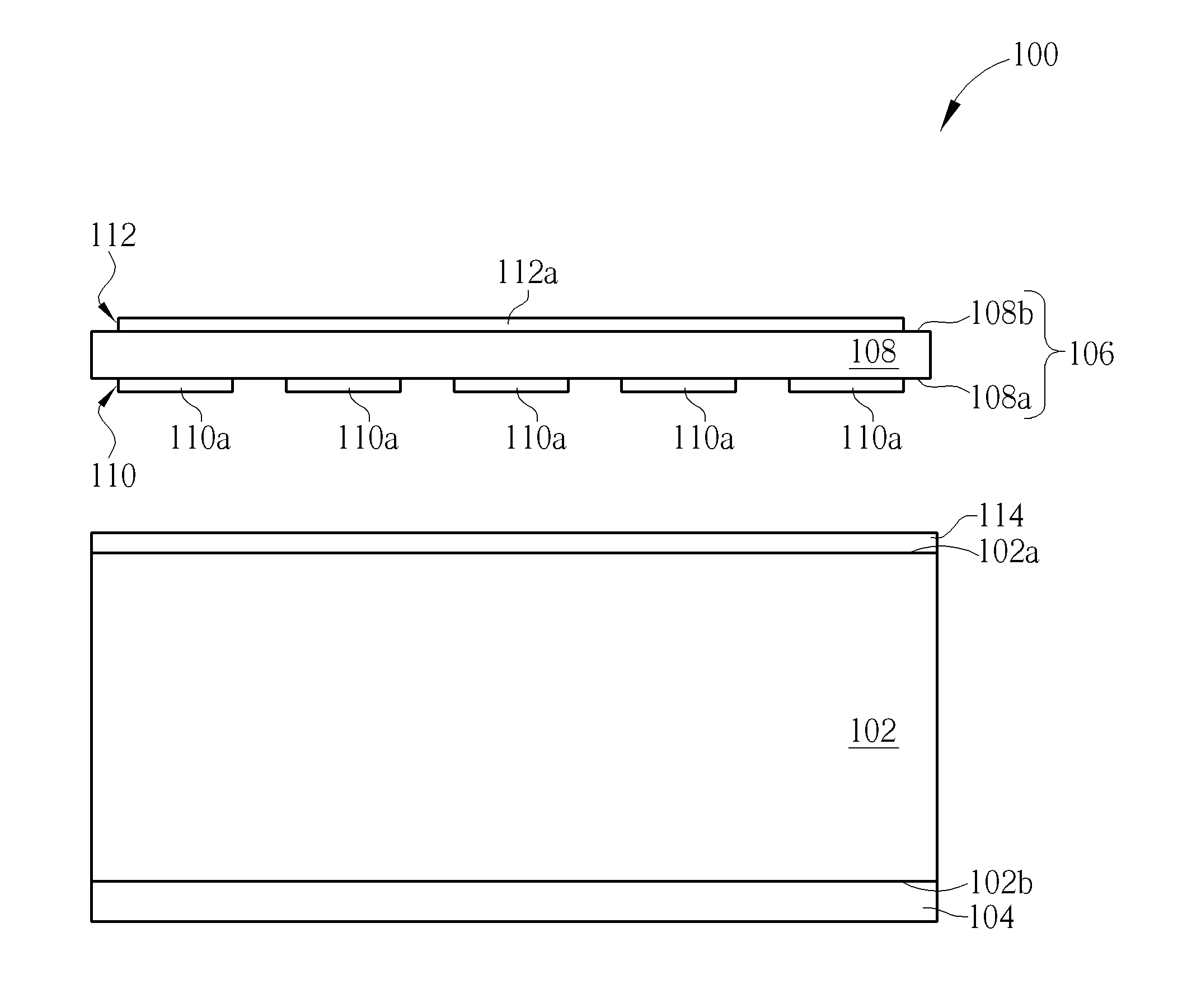

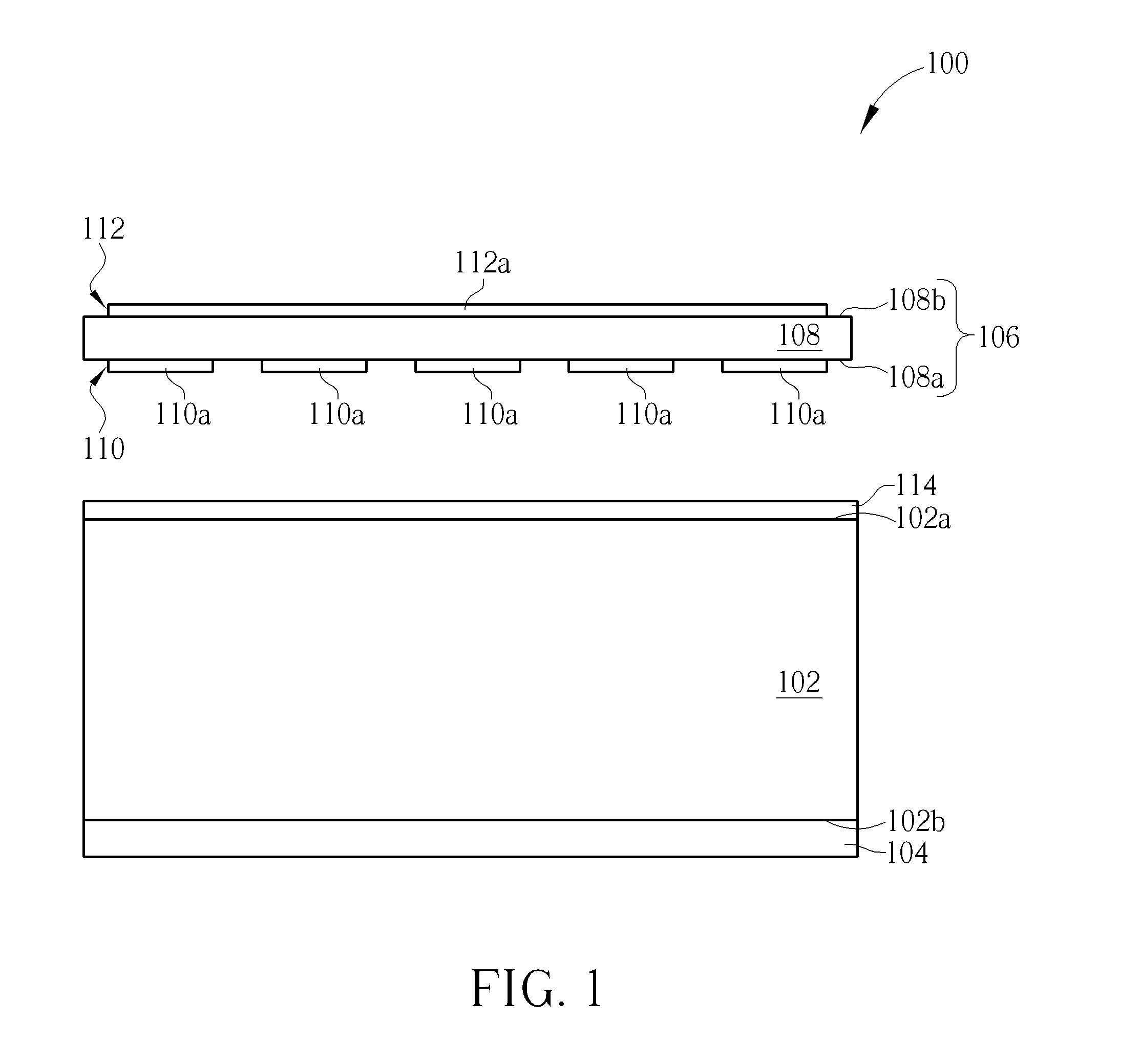

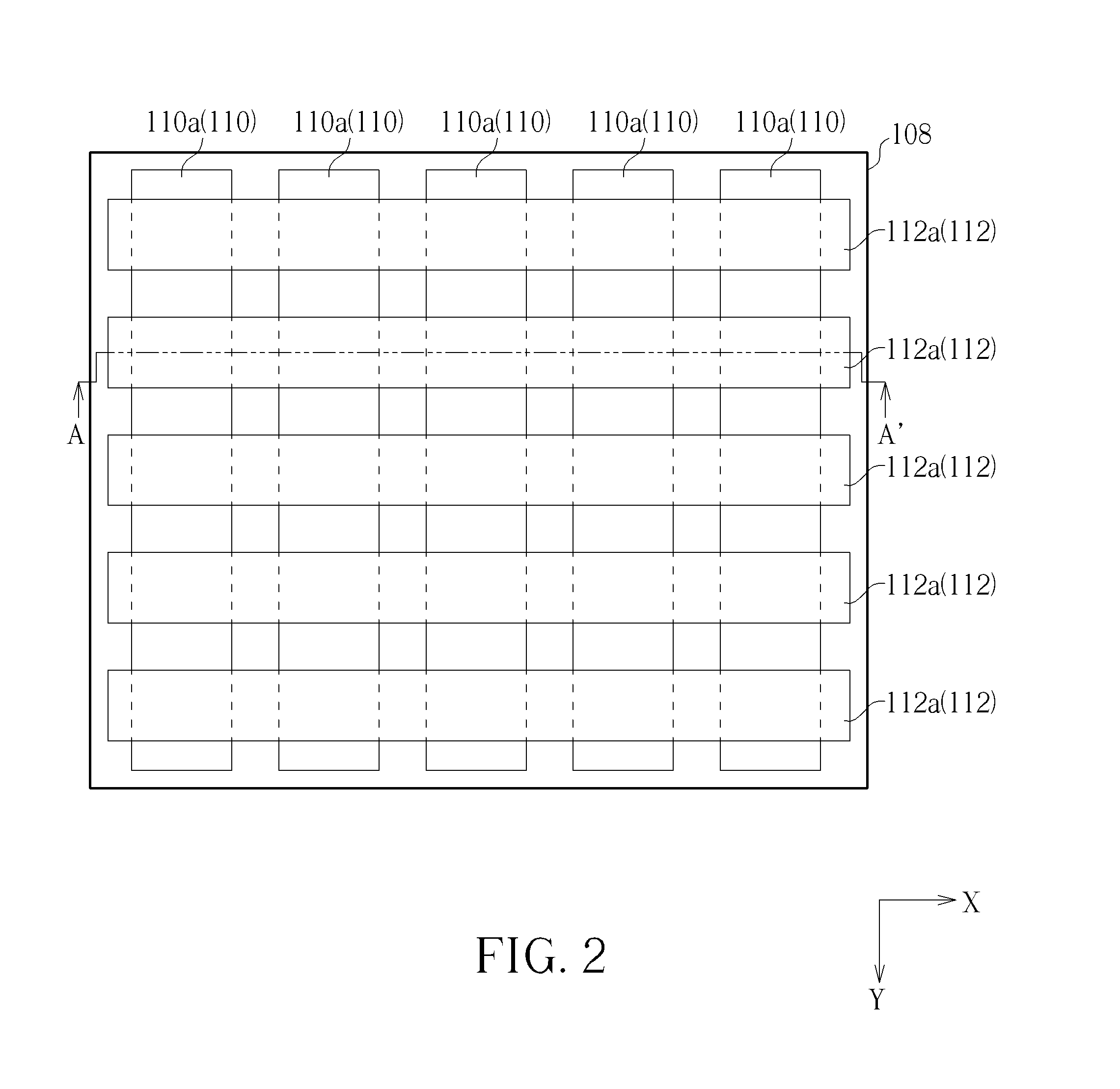

[0021]Please refer to FIG. 1 and FIG. 2. FIG. 1 is a schematic diagram illustrating an exploded cross-sectional view of a touch-sensing liquid crystal display panel according to a first embodiment of the present invention, and FIG. 2 is a schematic diagram illustrating a top view of a touch-sensing panel according to the first embodiment of the present invention, wherein FIG. 1 is the exploded cross-sectional view of FIG. 2 taken along a cross-sectional line A-A′. As shown in FIG. 1, the touch-sensing liquid crystal display panel 100 includes a liquid crystal panel 102, a first polarization plate 104, and a touch-sensing panel 106. The liquid crystal panel 102 has a display surface 102a and a back s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com