Substrate treatment apparatus and substrate treatment method

a substrate treatment and treatment apparatus technology, applied in the direction of instruments, cleaning using liquids, inorganic non-surface active detergent compositions, etc., can solve the problem of resist damage to the front surface of the wafer uncovered with resist, and achieve the effect of strong oxidative power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

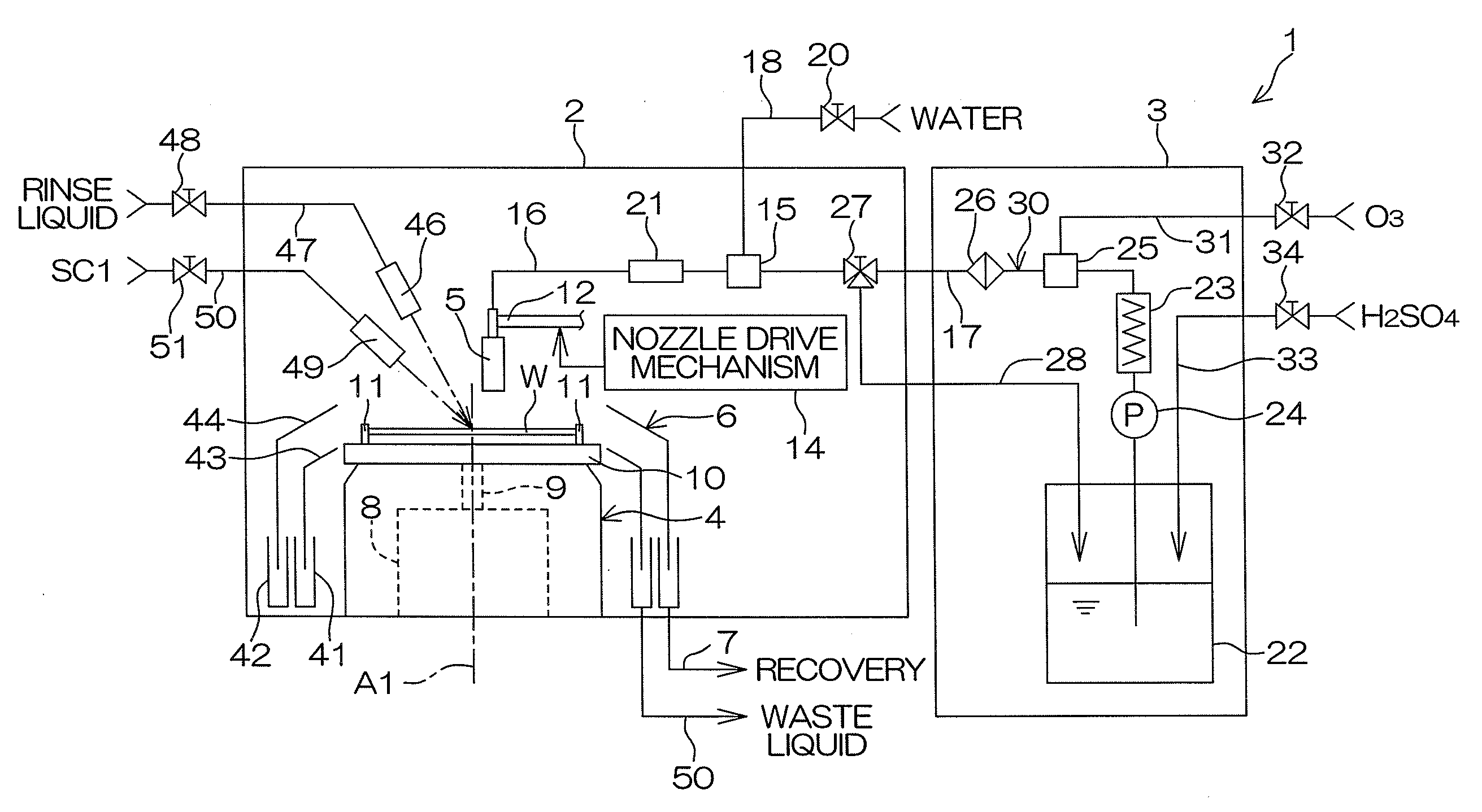

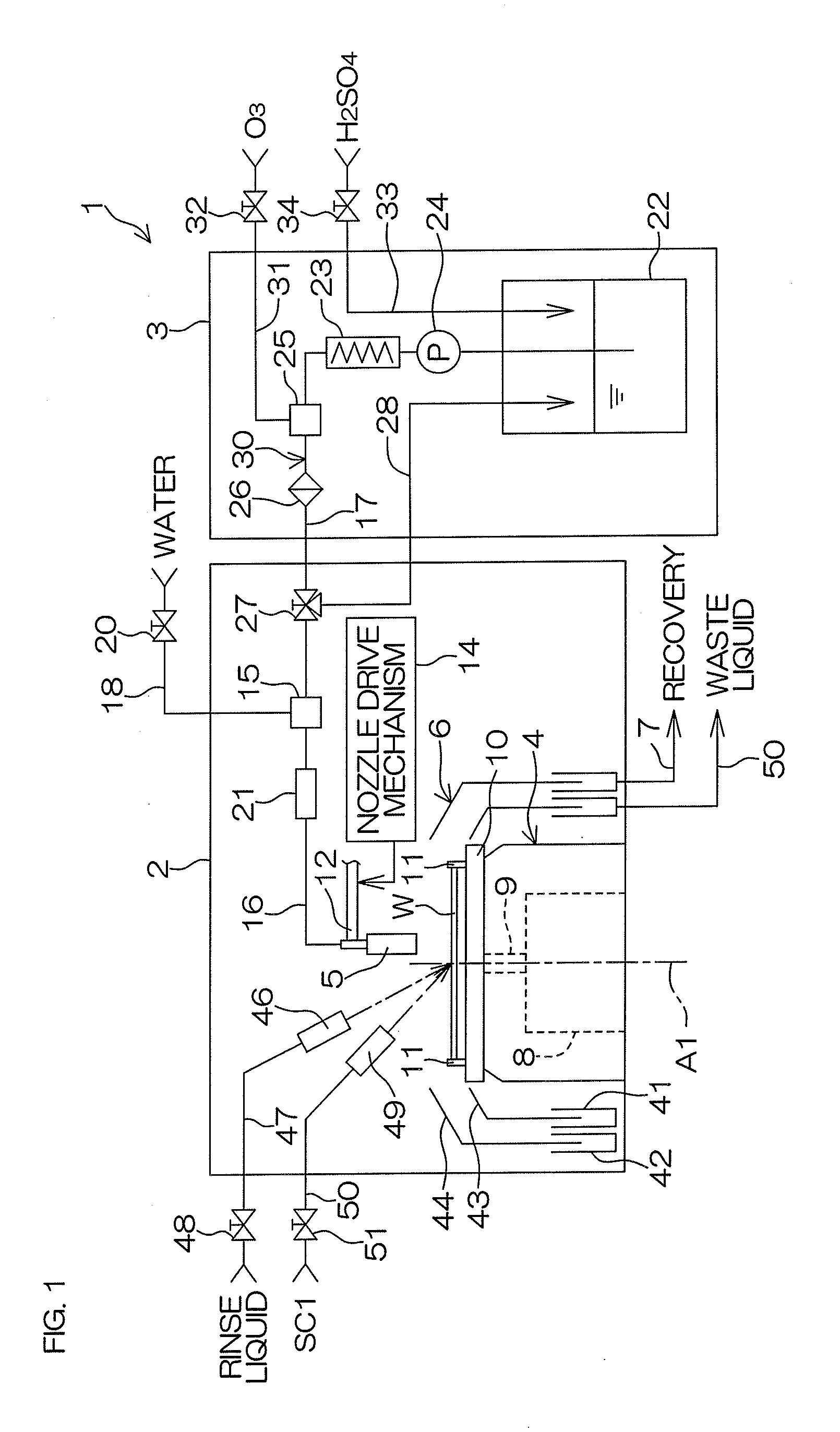

Method used

Image

Examples

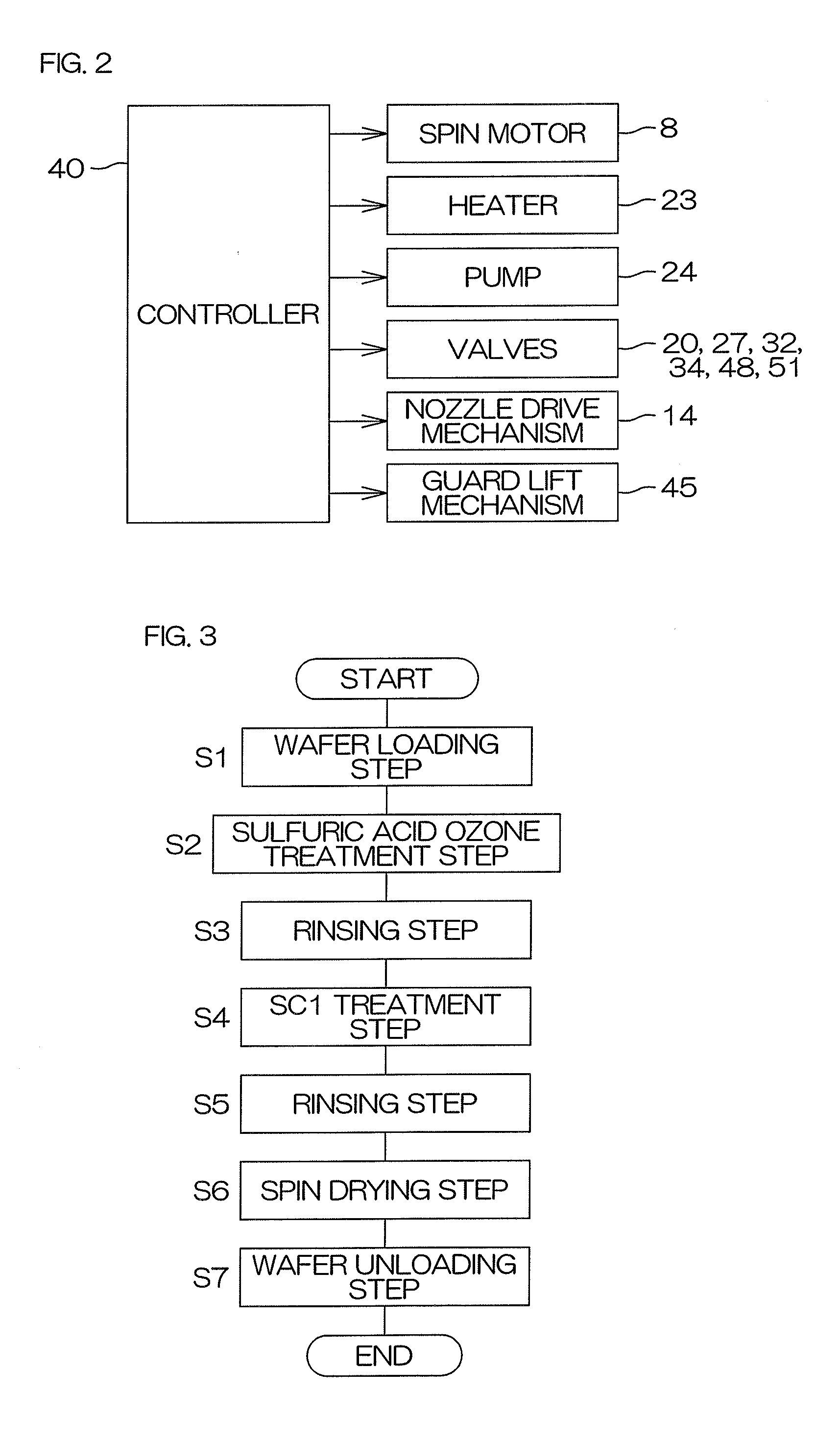

example 1

[0083]The flow rate ratio (weight ratio) between the sulfuric acid ozone (SOM) and the DIW in the sulfuric acid ozone / water mixture was 1:0.15 by way of example.

[0084]The liquid temperature (treatment temperature) of the sulfuric acid ozone / water mixture spouted from the sulfuric acid ozone / water nozzle 5 after the mixing was 134° C.

example 2

[0085]The flow rate ratio (weight ratio) between the sulfuric acid ozone and the DIW in the sulfuric acid ozone / water mixture was 1:0.3 by way of example. The liquid temperature (treatment temperature) of the sulfuric acid ozone / water mixture spouted from the sulfuric acid ozone / water nozzle 5 after the mixing was 151° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com