Process for liquefaction of natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

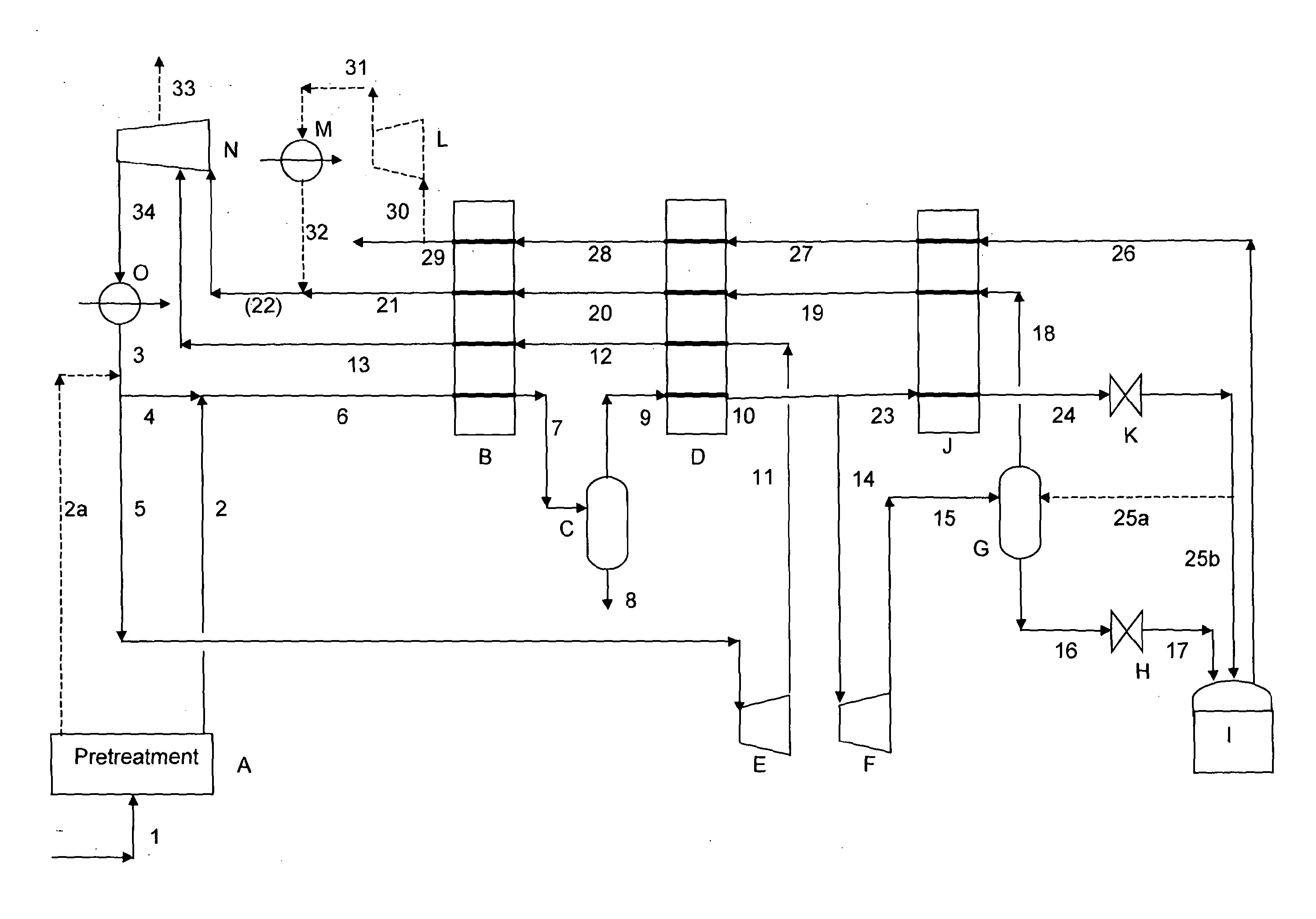

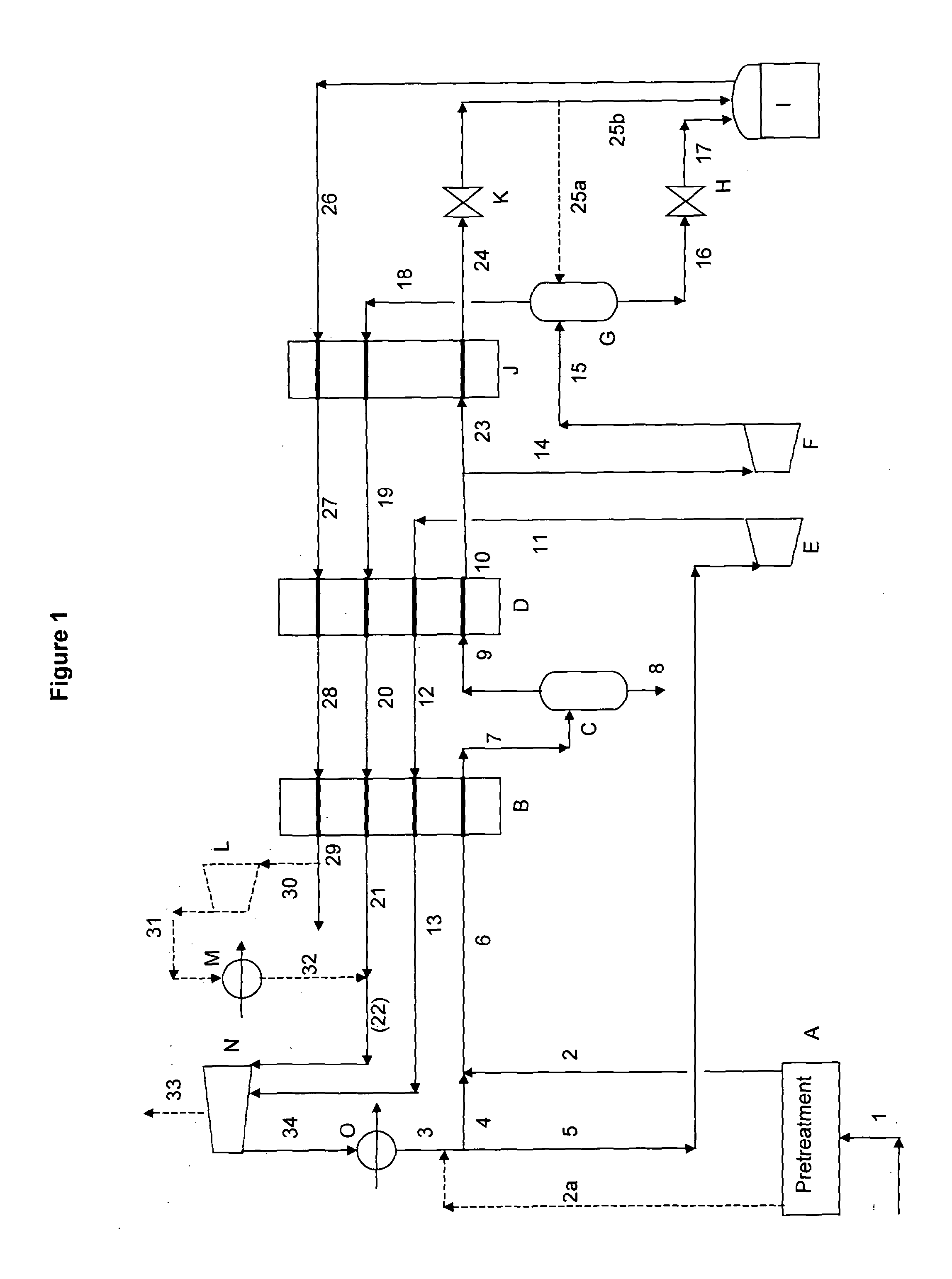

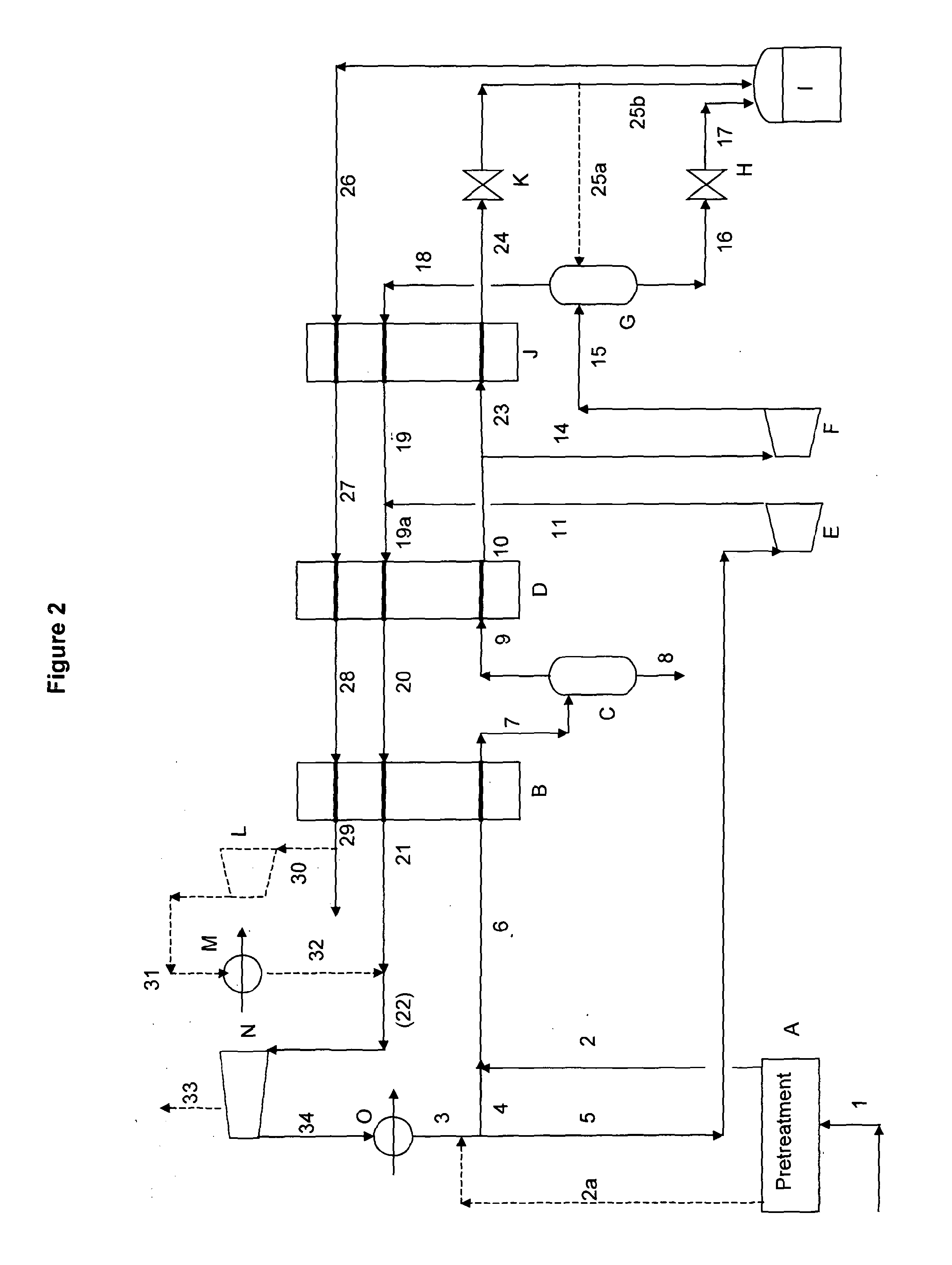

[0020]According to the invention, there is provided a process for liquefying natural gas or other methane-rich gases. The feed gas, generally at a pressure of from 40 (4 MPa) to 100 bar (10 MPa), is liquefied to give LNG product at approx 1 bar (0.1 MPa) / −161° C. by the expander-based plant configuration described above Sand comprising:[0021]cooling feed gas and recycle gas (mentioned below) in a first step by means of a first heat exchanger and in a first work expander; the heat exchanger having an outlet temperature in the range of −50° to −80° C., preferably −60° to −70° C.; the expander having a lower outlet temperature than that of the heat exchanger; the expander having its outlet stream reheated in a cold passage of the said heat exchanger and then recompressed to form part of the above mentioned recycle gas.[0022]passing the cooled outlet stream from the said first heat exchanger partly into a hot passage in a second heat exchanger, wherein it is essentially condensed, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com