Subsea Cable Termination Assembly, Subsea Connector and Method

a technology of subsea cable and connector, which is applied in the direction of mechanical equipment, coupling device connection, instruments, etc., can solve the problems of limited physical length of communication links, relatively complex connectors, and high cost of design and production. achieve the effect of reducing cost and high bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]In the following, embodiments illustrated in the accompanying drawings are described in more detail. The following description is only illustrative and non restrictive. The drawings are only schematic representations, and elements in the drawings are not necessarily to scale with each other.

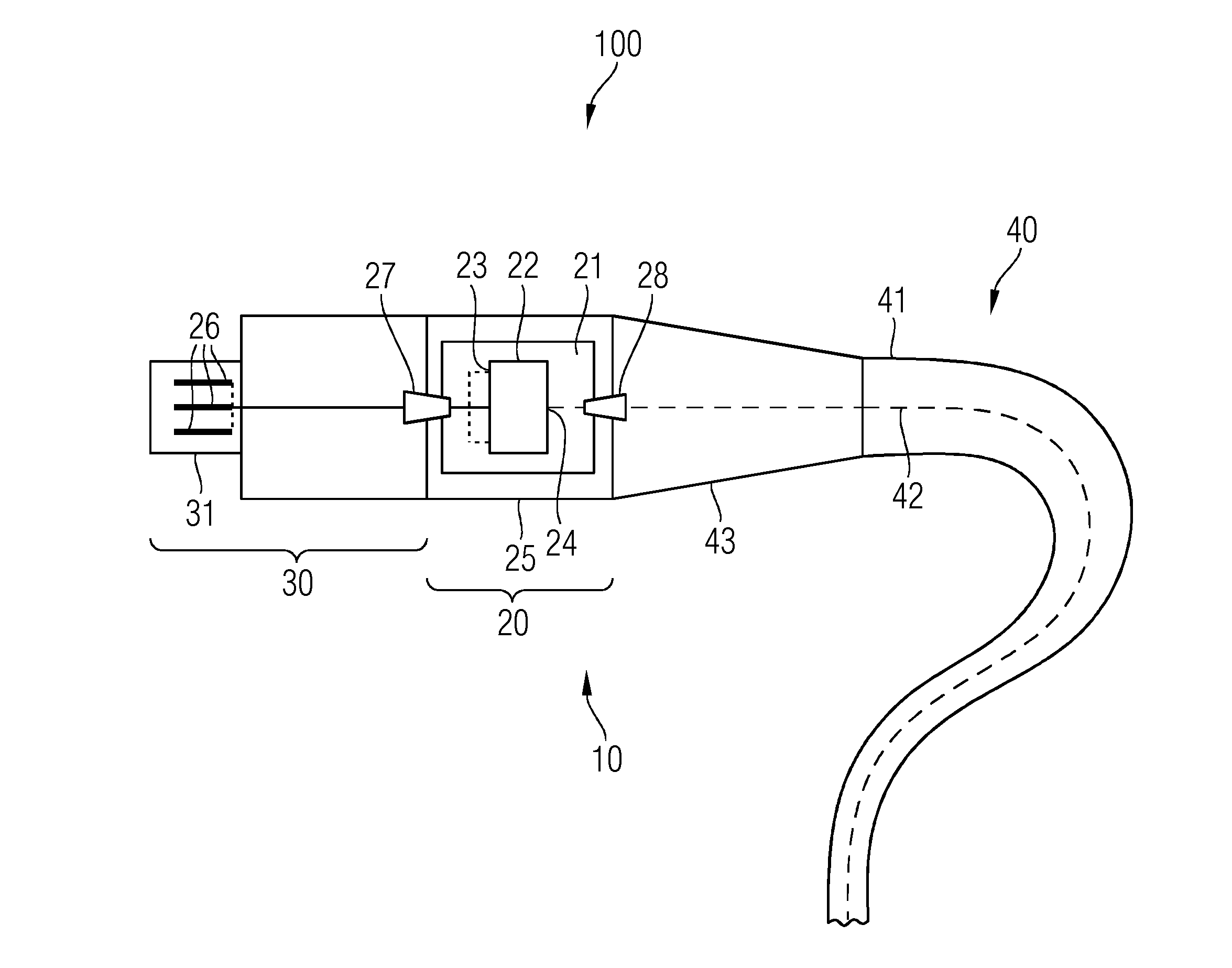

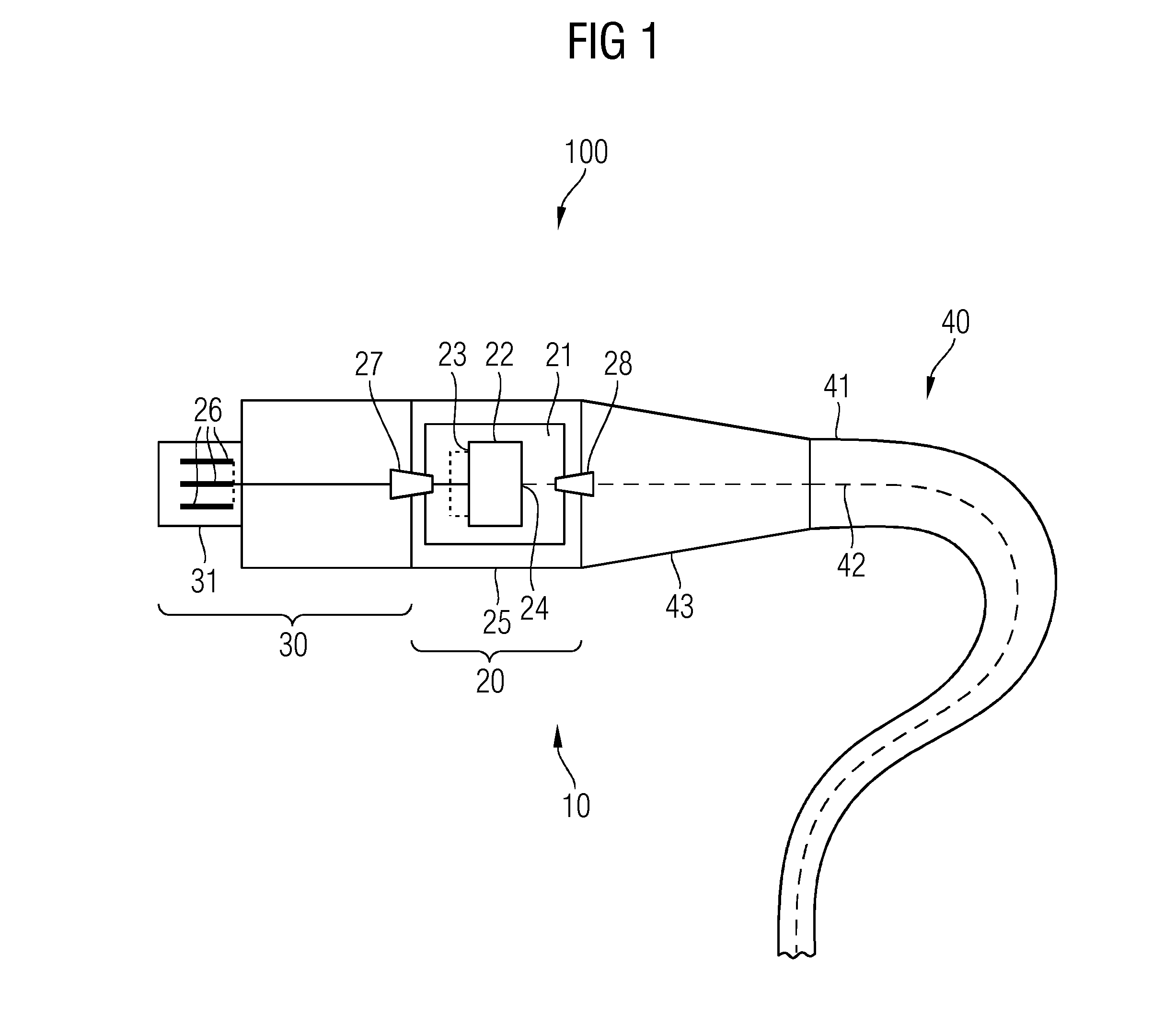

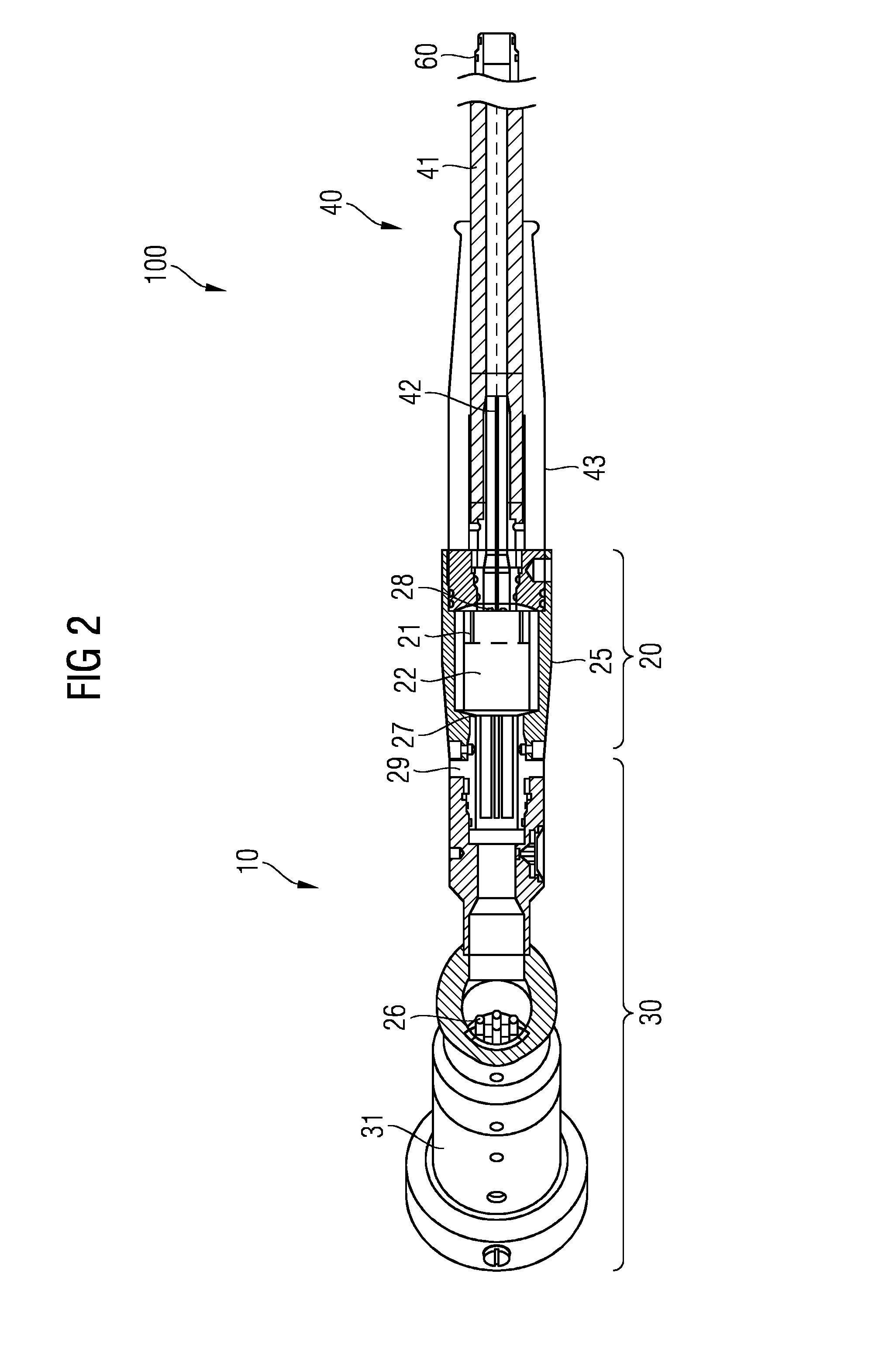

[0043]FIG. 1 shows one embodiment of a subsea cable assembly 100 including a subsea connector 10 and a subsea cable 40. The subsea connector 10 includes a subsea cable termination assembly 20 and a connector portion 30. Although the subsea cable termination assembly 20 and the connector portion 30 are shown as separate elements, the subsea cable termination assembly 20 and the connector portion 30 may in other embodiments be parts of a subsea connector and may not be separable.

[0044]The subsea connector 10 may be implemented as a male or a female connector. In the embodiments described hereinafter, the subsea connector 10 is a wet mateable connector, although implementations as a dry mate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com