Cooling system

a cooling system and cooling technology, applied in heat pumps, lighting and heating apparatus, transportation and packaging, etc., can solve the problems of reducing the cooling performance of the vehicle, reducing the cooling efficiency of the vehicle, and increasing so as to reduce the power consumption of the compressor and reliably cool the heat generating source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

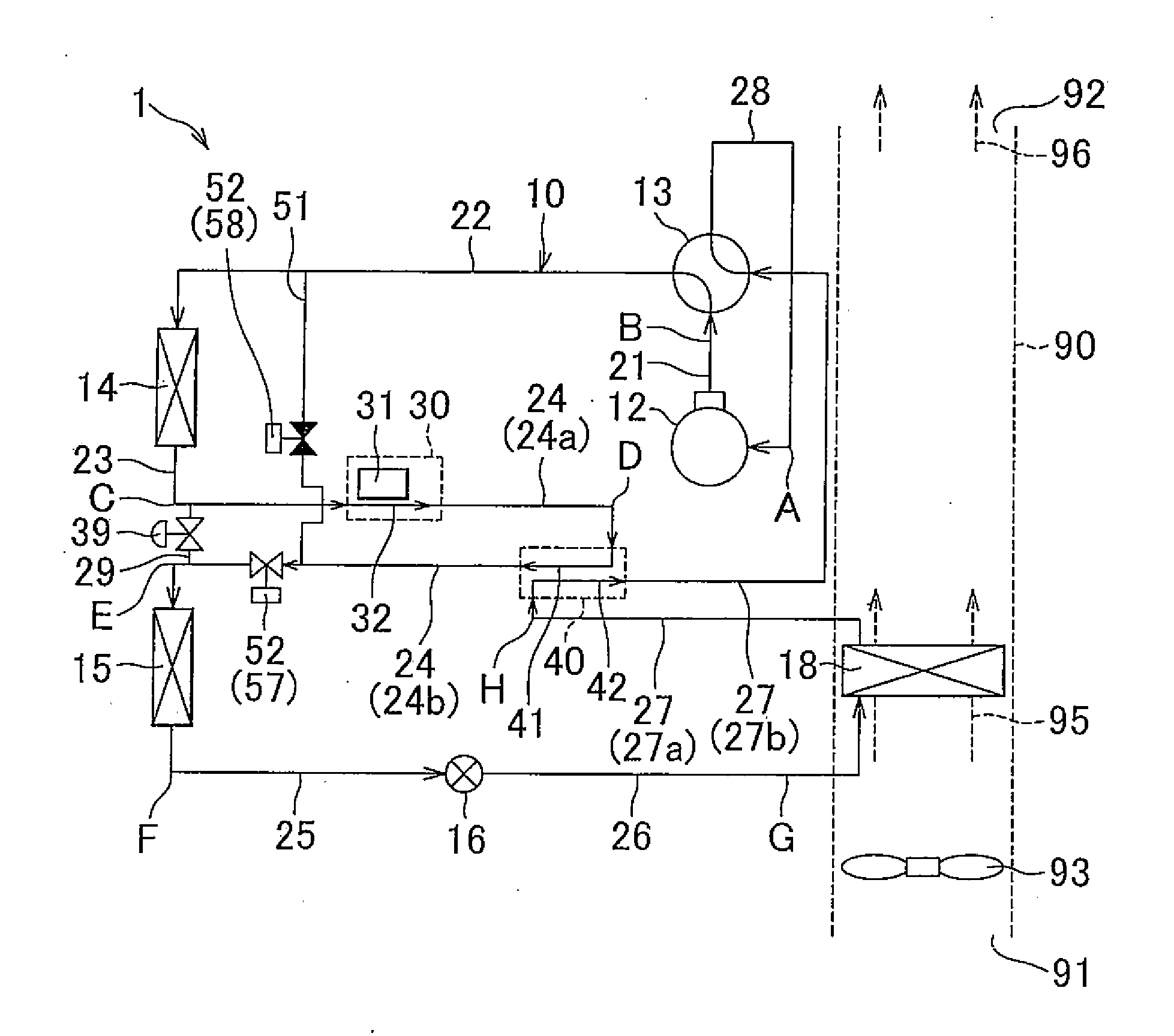

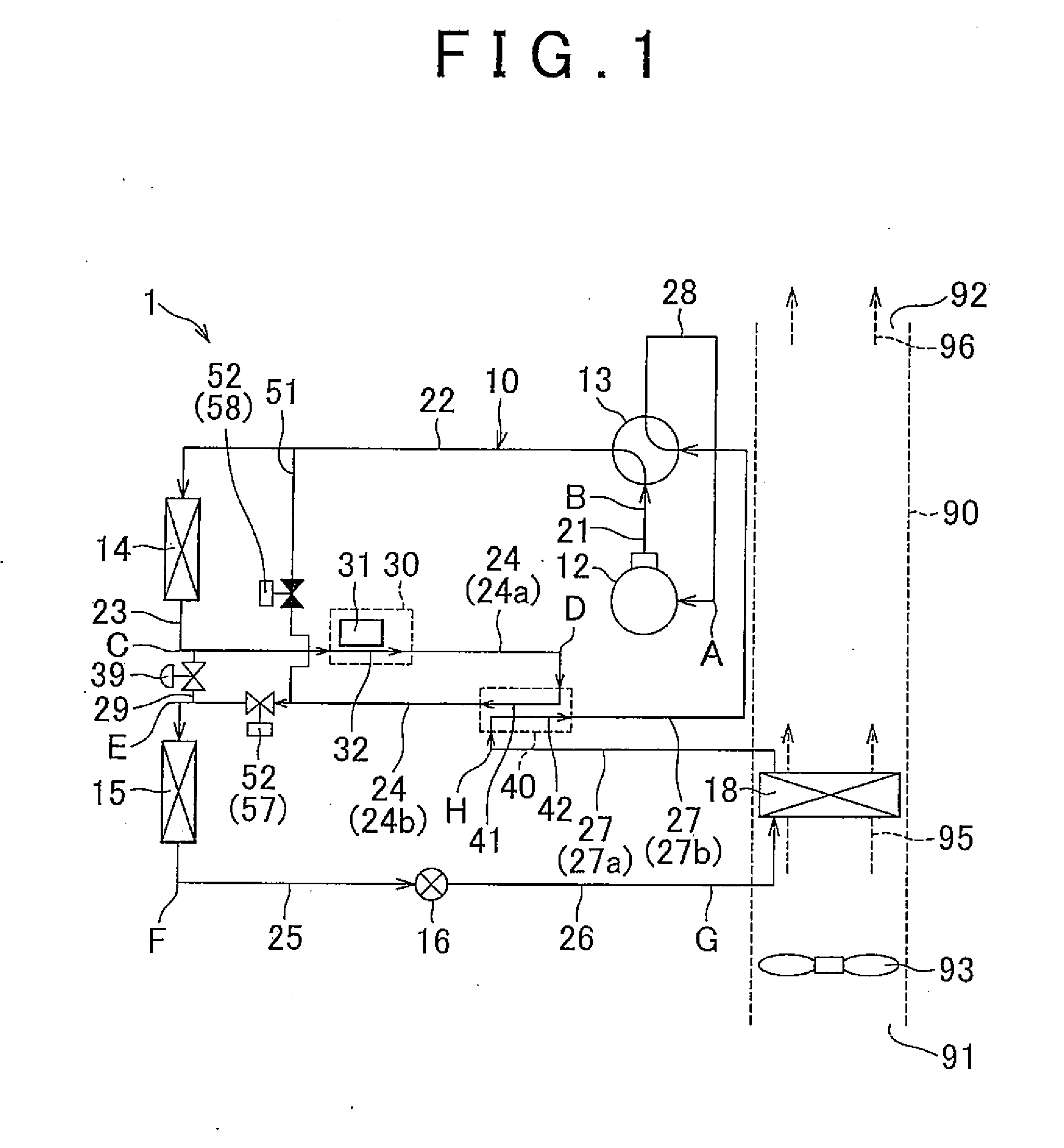

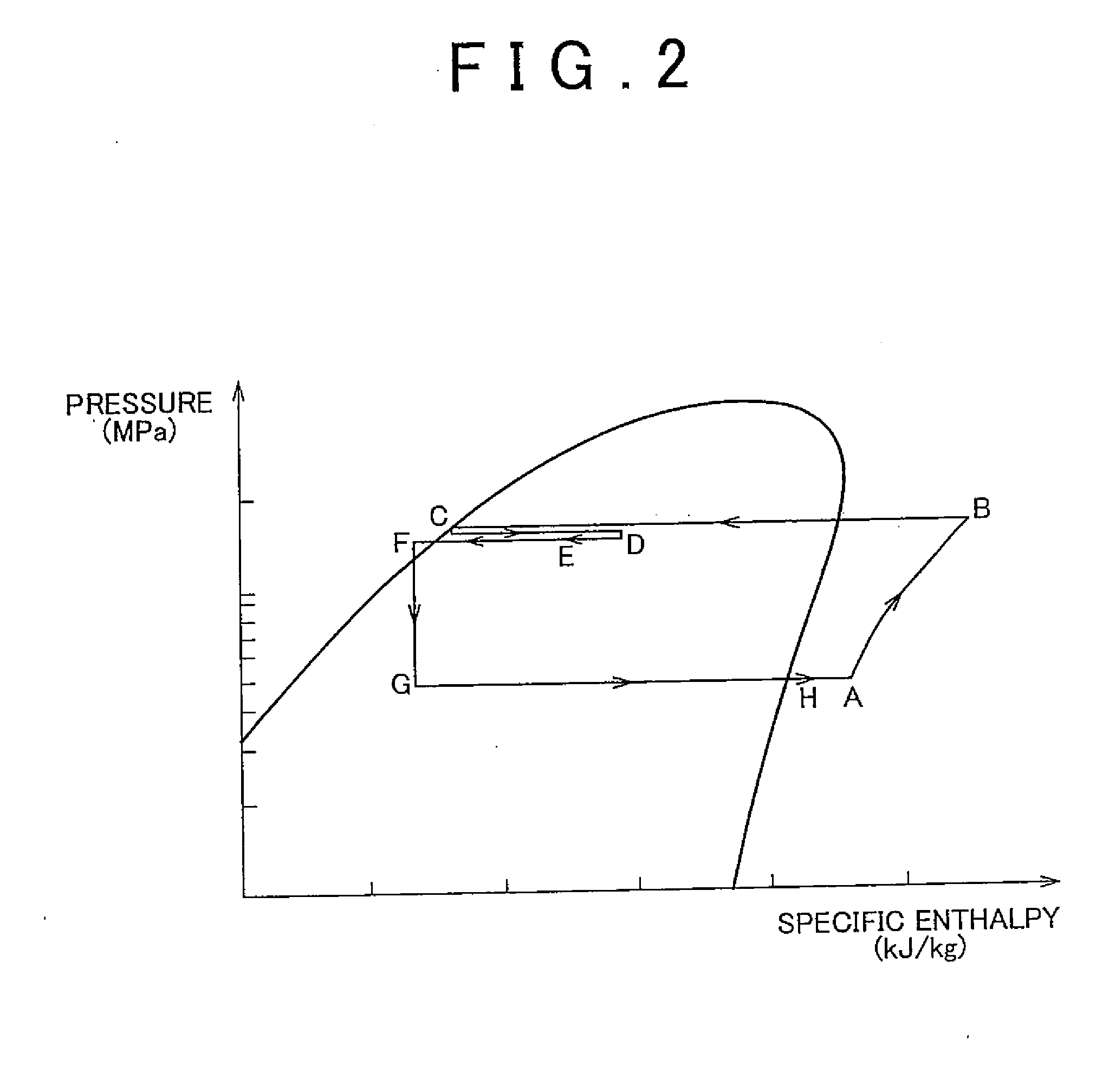

[0026]FIG. 1 is a schematic view that shows the configuration of a cooling system 1 according to a first embodiment. As shown in FIG. 1, the cooling system 1 includes a vapor compression refrigeration cycle 10. The vapor compression refrigeration cycle 10 is, for example, mounted on a vehicle in order to cool or heat the cabin of the vehicle. Cooling using the vapor compression refrigeration cycle 10 is performed, for example, when a switch for cooling is turned on or when an automatic control mode in which the temperature in the cabin of the vehicle is automatically adjusted to a set temperature is selected and the temperature in the cabin is higher than the set temperature. Heating using the vapor compression refrigeration cycle 10 is performed, for example, when a switch for heating is turned on or when the automatic control mode is selected and the temperature in the cabin is lower than the set temperature.

[0027]The vapor compression refrigeration cycle 10 includes a compressor ...

second embodiment

[0098]FIG. 8 is a schematic view that shows the configuration of a cooling system 1 according to a second embodiment. The cooling system 1 according to the second embodiment differs from the cooling system 1 according to the first embodiment in that the heat exchanger 14 and the heat exchanger 15 are manufactured as an integrated heat exchanger.

[0099]FIG. 9 is a schematic view that shows an example of the internal structure of the heat exchangers 14 and 15 according to the second embodiment. As shown in FIG. 9, the heat exchanger 14 and the heat exchanger 15 are integrally arranged. The integrally arranged heat exchanger 14 and heat exchanger 15 are, for example, provided next to an engine cooling radiator mounted on the vehicle, and carries out heat exchange between running wind of the vehicle or cooling air supplied by a cooling fan and refrigerant.

[0100]The heat exchanger 14 includes a plurality of tubes 146 through which refrigerant flows and a plurality of fins 148 that are use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com