Tubular heat exchanger

a technology of heat exchanger and tubular tube, which is applied in the direction of superimposed coating process, corrosion prevention, stationary tubular conduit assembly, etc., can solve the problems of reduced space in factories, difficult positioning of tubular tube in closed spaces, and production of treated products whose thermal characteristics may not be suitable for us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

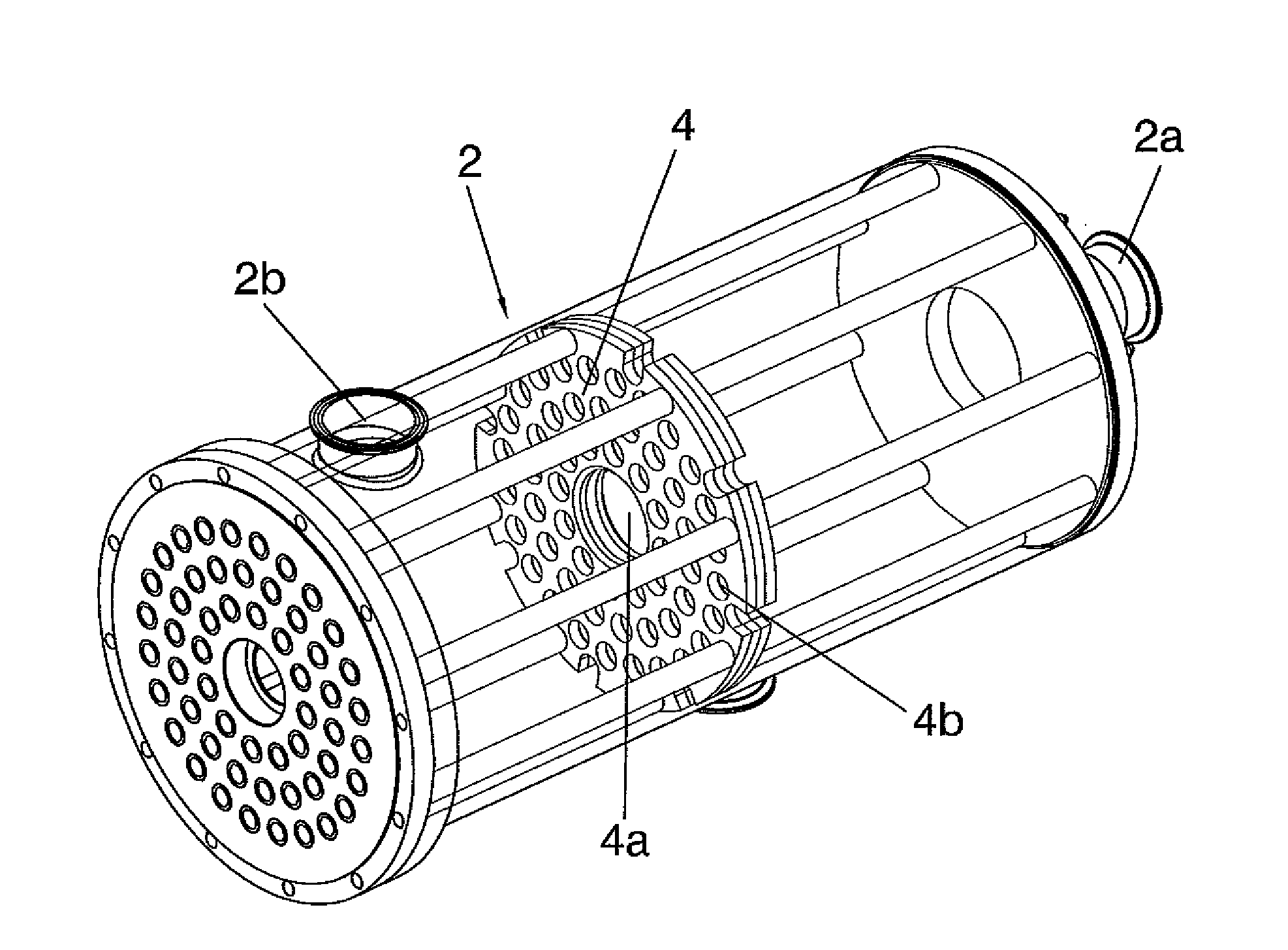

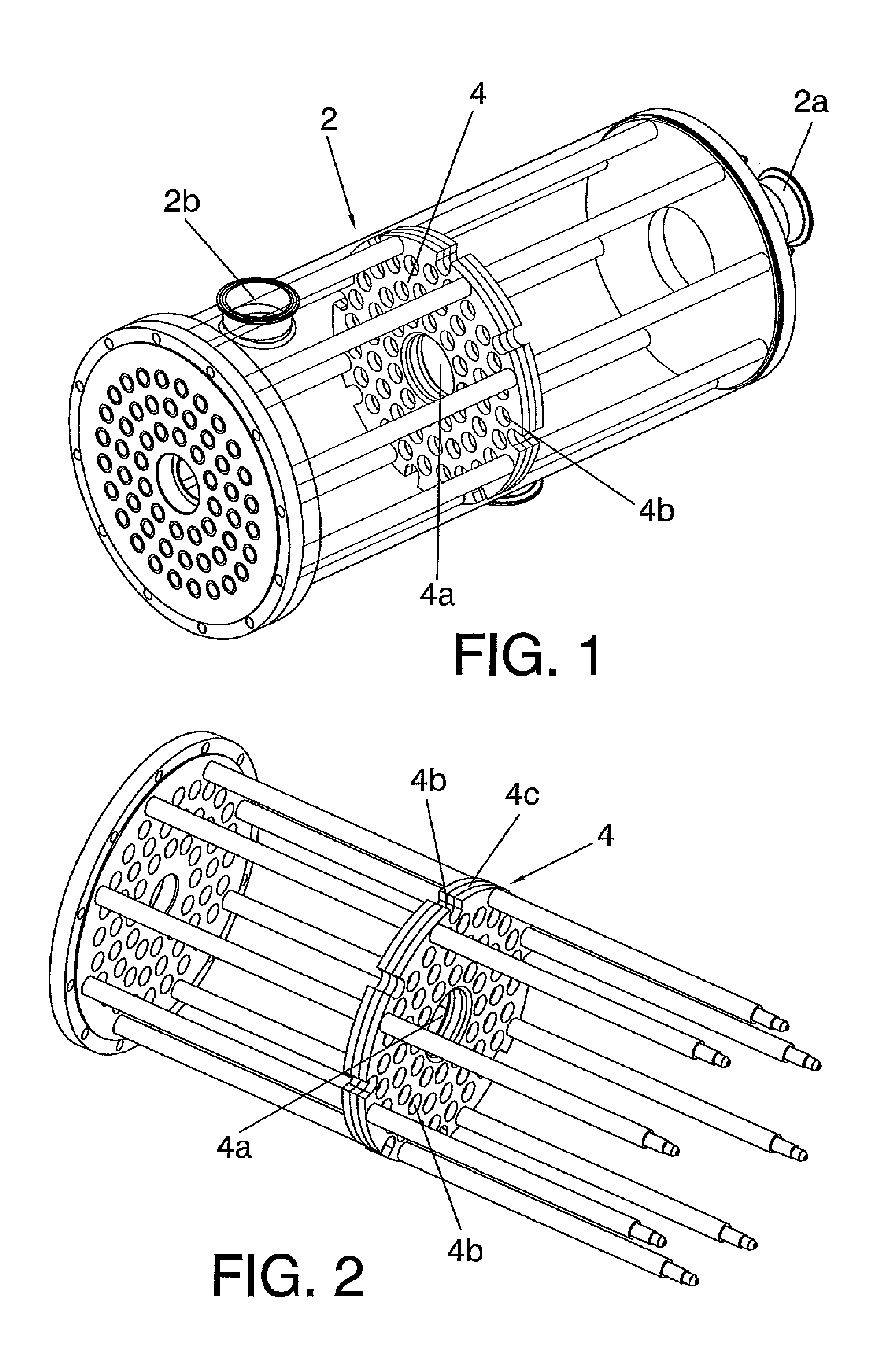

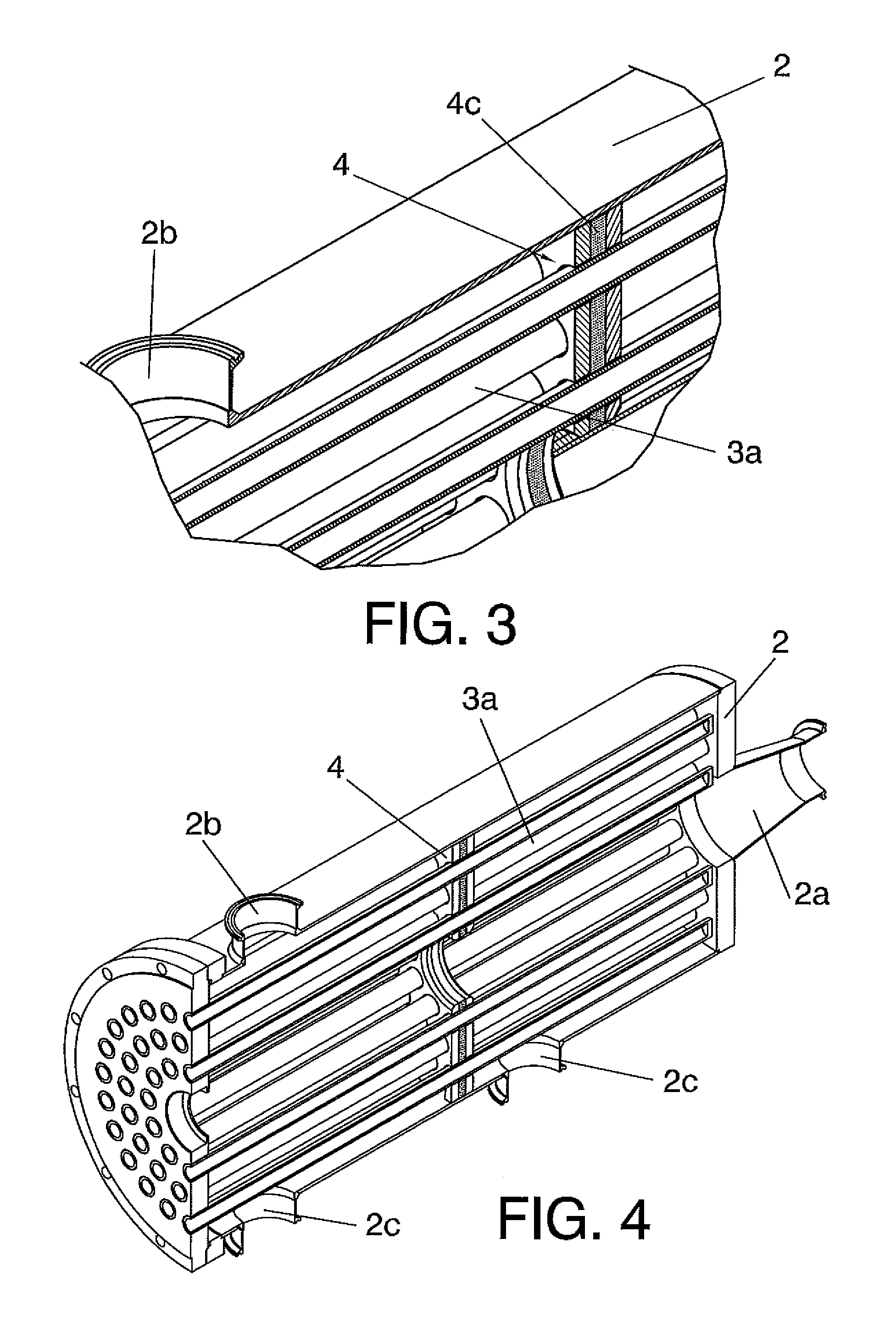

[0009]The present invention relates to a tubular heat exchanger comprising the following technical features:[0010]a tubular sleeve comprising an inlet for the entrance of a product to be thermally treated, and an outlet for the exit of said thermally treated product;[0011]a first plurality of tubes carrying a heat transfer fluid which are located inside the tubular sleeve; where said first plurality of tubes can be of one and the same tube wound inside the exchanger, or can be part of independent tubes with a common inlet for the entrance of the heat transfer fluid, and an also common outlet for the exit of said heat transfer fluid;[0012]at least one diaphragm located inside the tubular sleeve which divides the interior of the sleeve into at least two chambers, where said diaphragm comprises a central hole configured for allowing the passage of the product from the inlet to the outlet of the sleeve; and where said diaphragm comprises a plurality of holes configured for allowing the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com