Sanding disk alignment tool

a technology of sanding disk and tool, which is applied in the field of hand-held power tools, can solve the problems of affecting the effectiveness and lifespan of the abrasive disk, affecting the operator of the tool, and damaging the work surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 100

[0037]In its simplest and, perhaps, preferred form, the tool 10 of the present invention is made as a single unit formed of suitable material such as plastic (ABS, polystyrene, PVC, polycarbonate, polyurethane), wood or metal. Injection molded single part plastic construction may provide the most economical construction. However, unitary construction is limited in as much as the distance D and pin 20 diameter are fixed such that a given tool 10 is suitable for use with only a single sander platen dust extraction hole pattern. With reference to FIG. 7, an alternate embodiment of a tool 100 according to the present invention is depicted in which multiple pin configurations are possible. Tool 100 is provided with a longitudinal base member 112 substantially as described above with respect to base member 12 except that the base member 112 is selectively rotatable about its longitudinal axis X with respect to the handle 130. Additionally, two sets of pins 120 and 120′ are provided, one e...

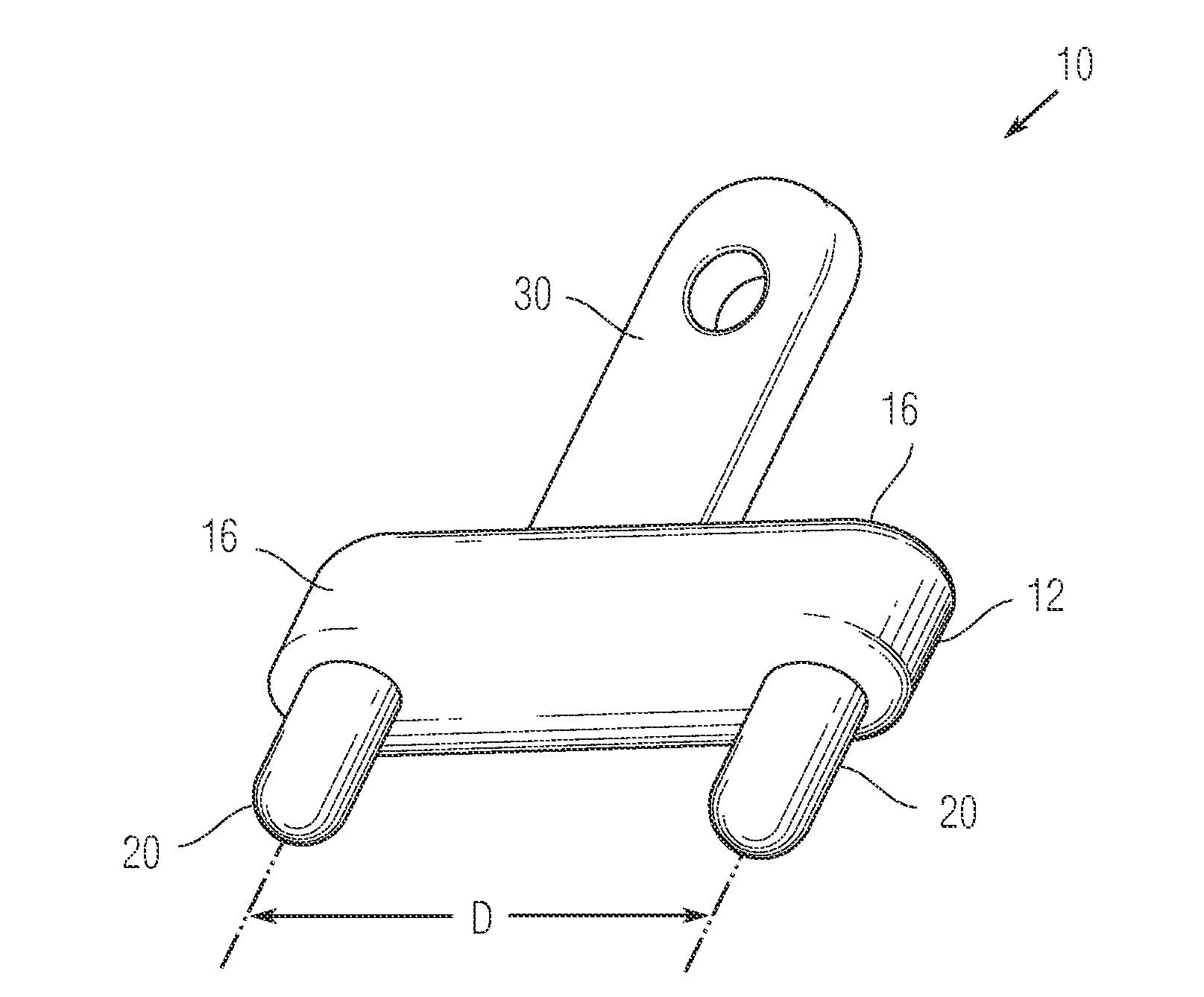

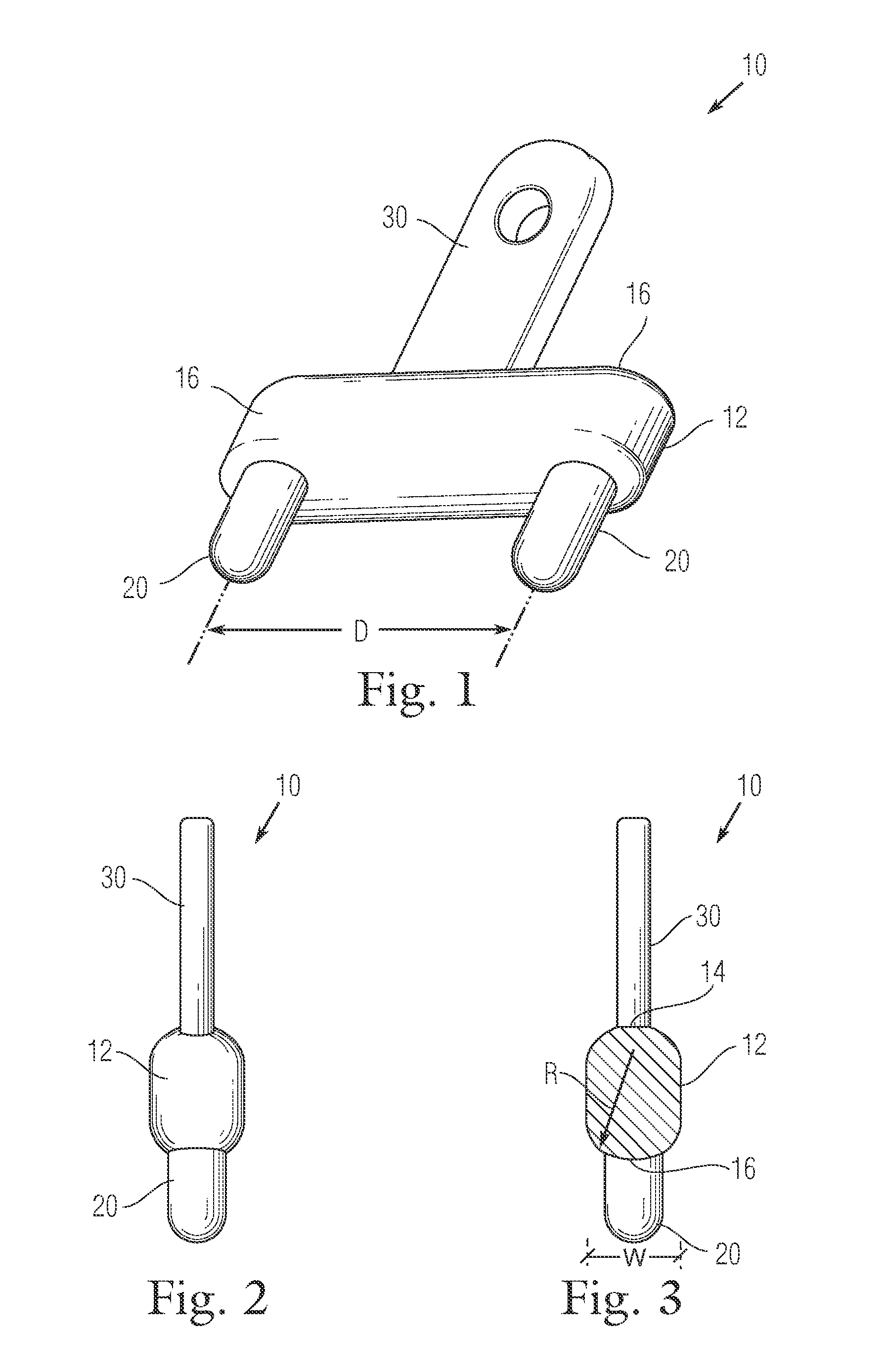

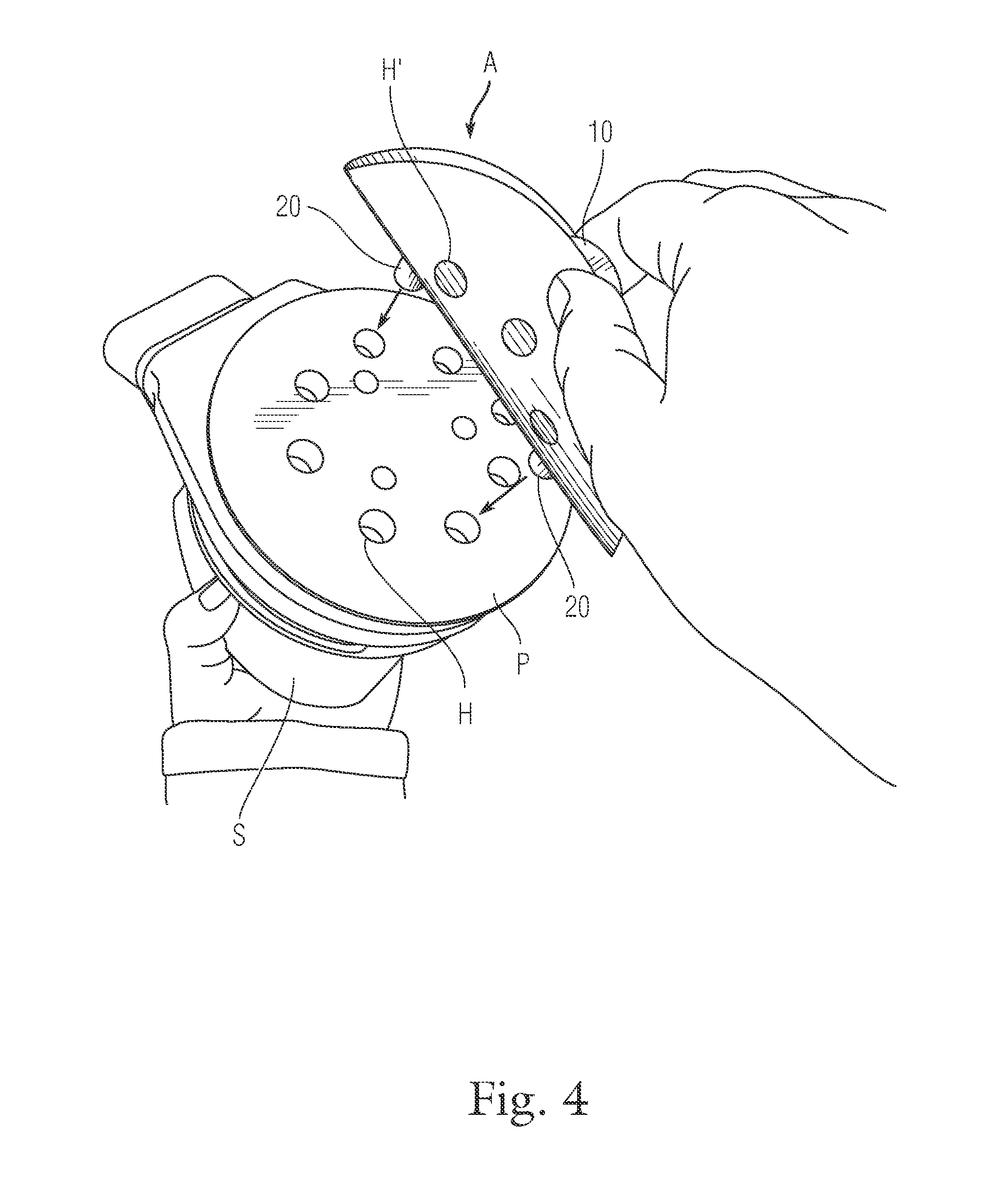

embodiment 10

[0038]With reference to FIG. 8, another alternate embodiment of a tool 200 according to the present invention is depicted. Tool 200 is comprised of a planar base member 212, preferably circular in form and having a diameter substantially equal to that of the sanding disk with which it is intended to be used. Planar base member 212 is preferably constructed of a strong, lightweight polymer that is flexible in sheet form such as, for example, acrylic, polyethylene, polycarbonate, or polyurethane. Alternately, planar base member 212 the may be formed of a rigid sheet plastic bent or bowed and fixed into a curved shape that resembles a traditional hard taco shell. A pair of pins 220 substantially similar to pins 20 are provided extending from one side of the planar base member 212. Pins 220 are preferably situated symmetrically with respect to the center of the preferably circular planar member and are positioned and sized for cooperative insertion into the dust extraction holes H of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com