Process for producing oil

a technology of oil production and process, applied in the direction of fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve the problems of difficult mobilization and production of viscous heavy oil or bituminous crudes, difficult recovery of oil or bitumen,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

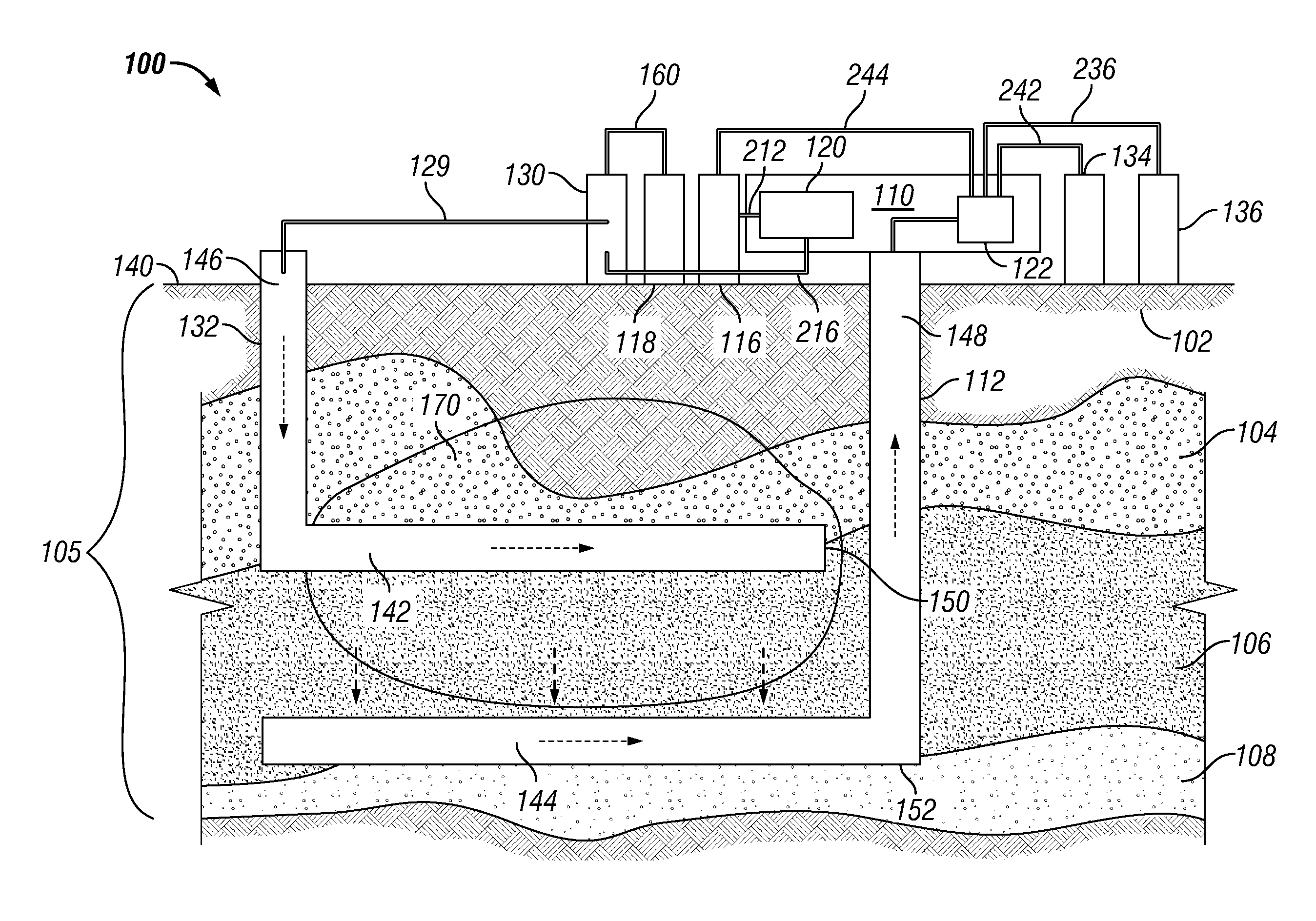

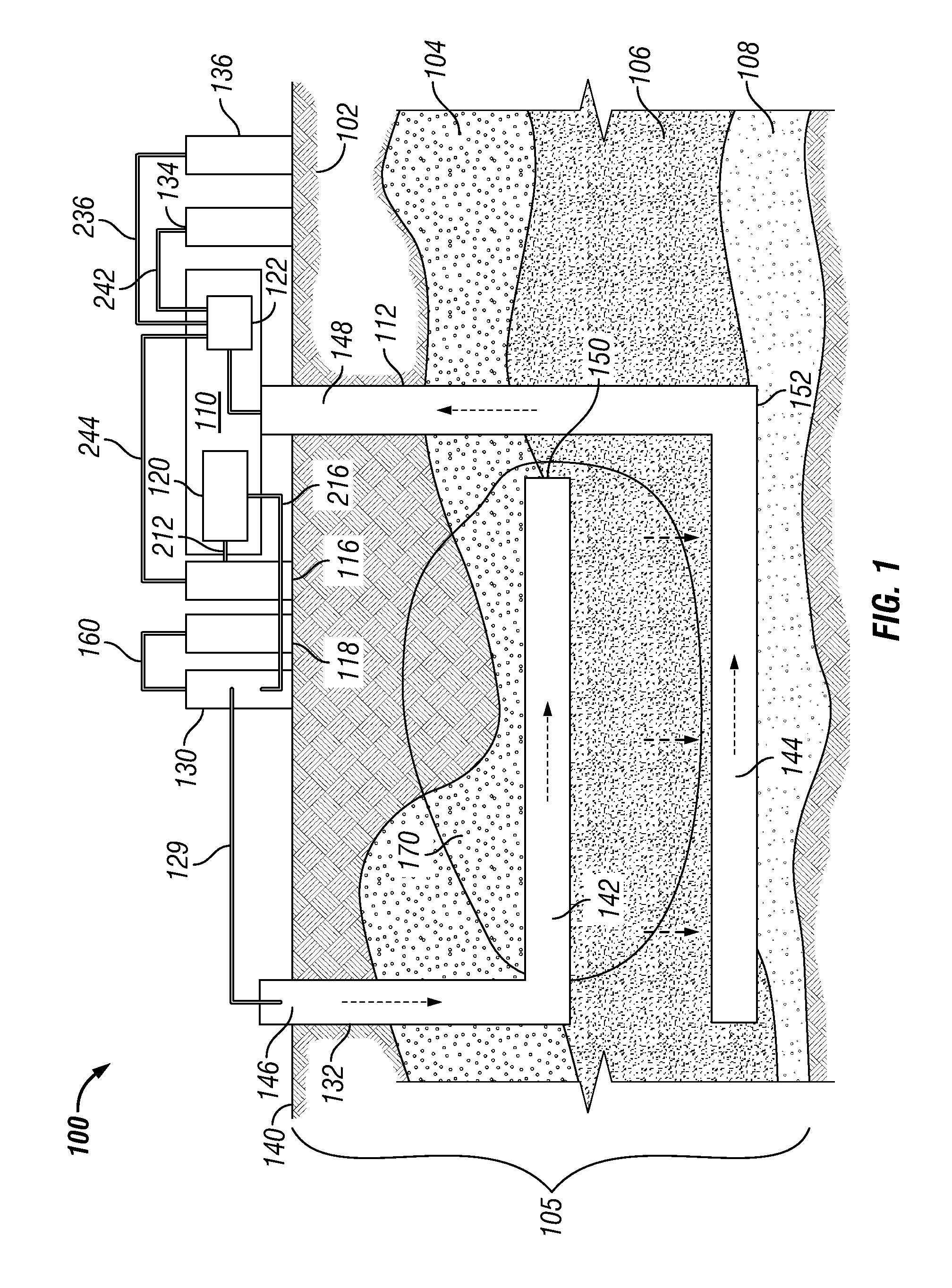

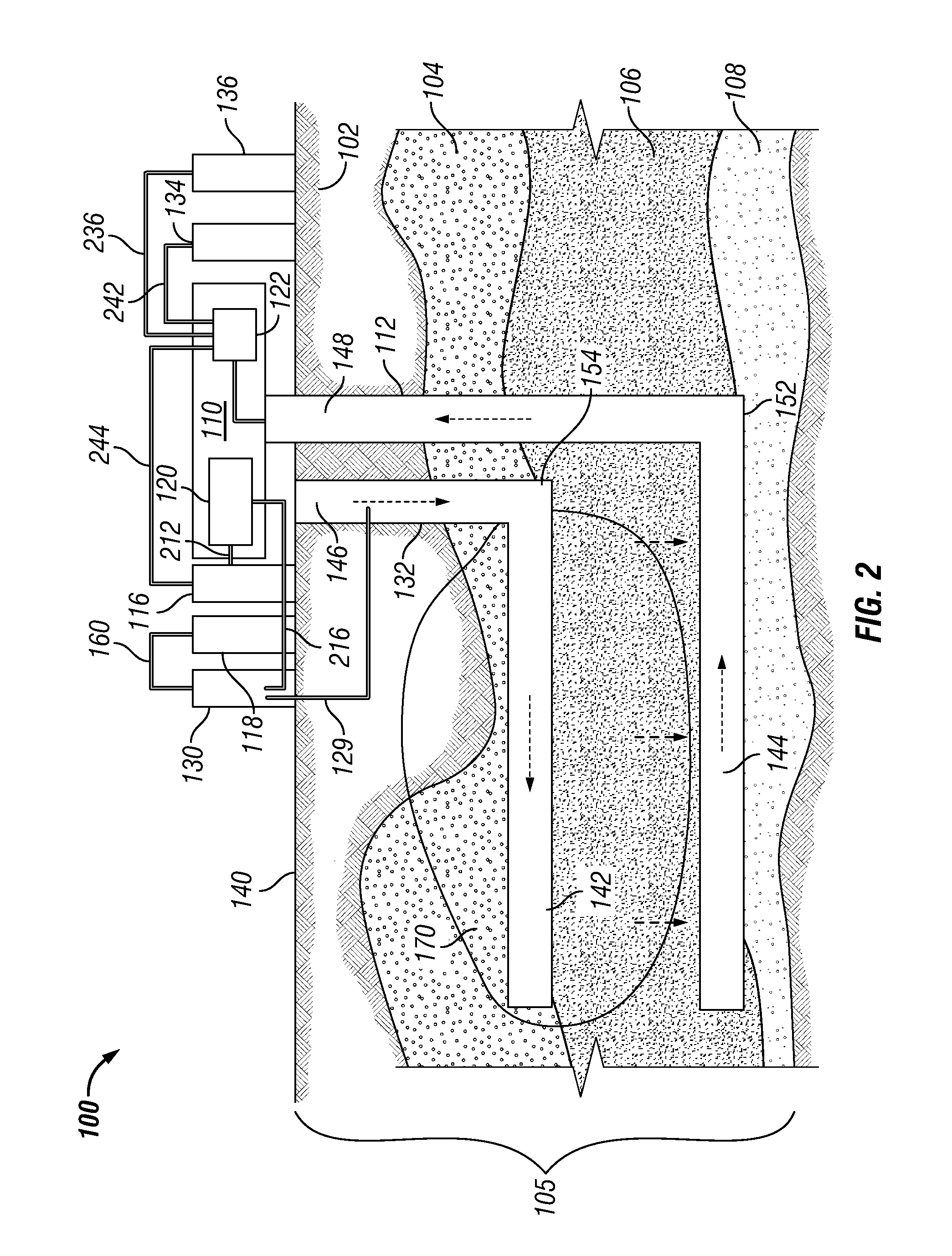

[0020]The present invention is directed to a process for enhancing the recovery of oil from a subterranean formation containing heavy oil or bitumen. An oil recovery formulation comprising ammonia and low quality steam—in particular, steam having a vapor quality of less than 0.7—may be injected into the formation and oil may be produced from the formation after injection of the oil recovery formulation into the formation. The combination of ammonia and low quality steam in the oil recovery formulation produces ammonium hydroxide in the liquid phase aqueous condensate portion of the low quality steam so that the ammonium hydroxide is present in the oil recovery formulation as the oil recovery formulation is injected into the formation. The ammonium hydroxide may react with petroleum acids, e.g. naphthenic acids, in the bitumen or heavy oil in the immediate vicinity of the injecting well to form an oil-emulsifying soap that promotes the formation of an oil-in-water emulsion with conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com