Rotary steerable system for vertical drilling

a technology of vertical drilling and steerable equipment, which is applied in the direction of surveying, directional drilling, and well accessories, etc., can solve the problems of high cost, ineffective cost, and high cost of current steerable drilling equipment, and it is costly for operators to have both conventional drilling systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

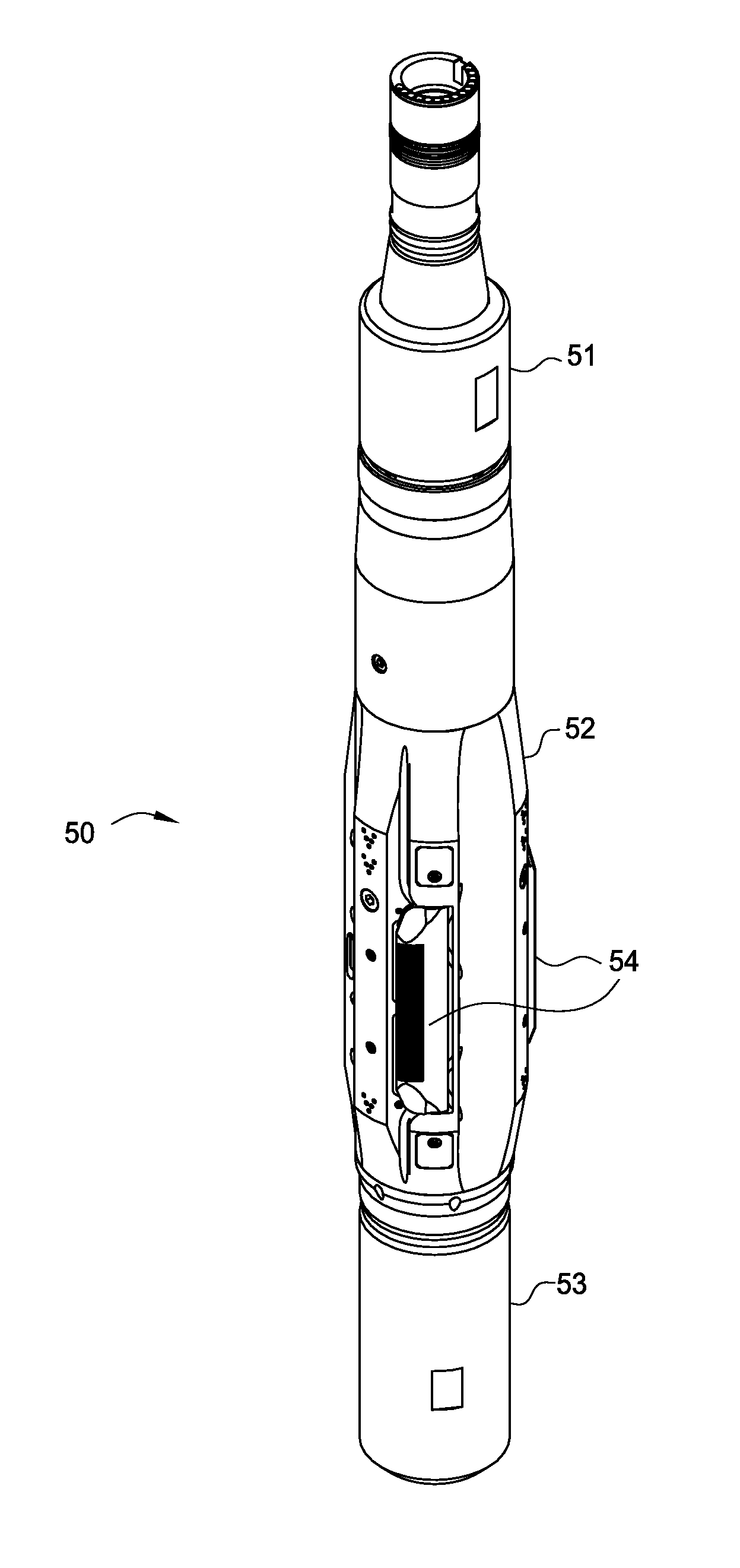

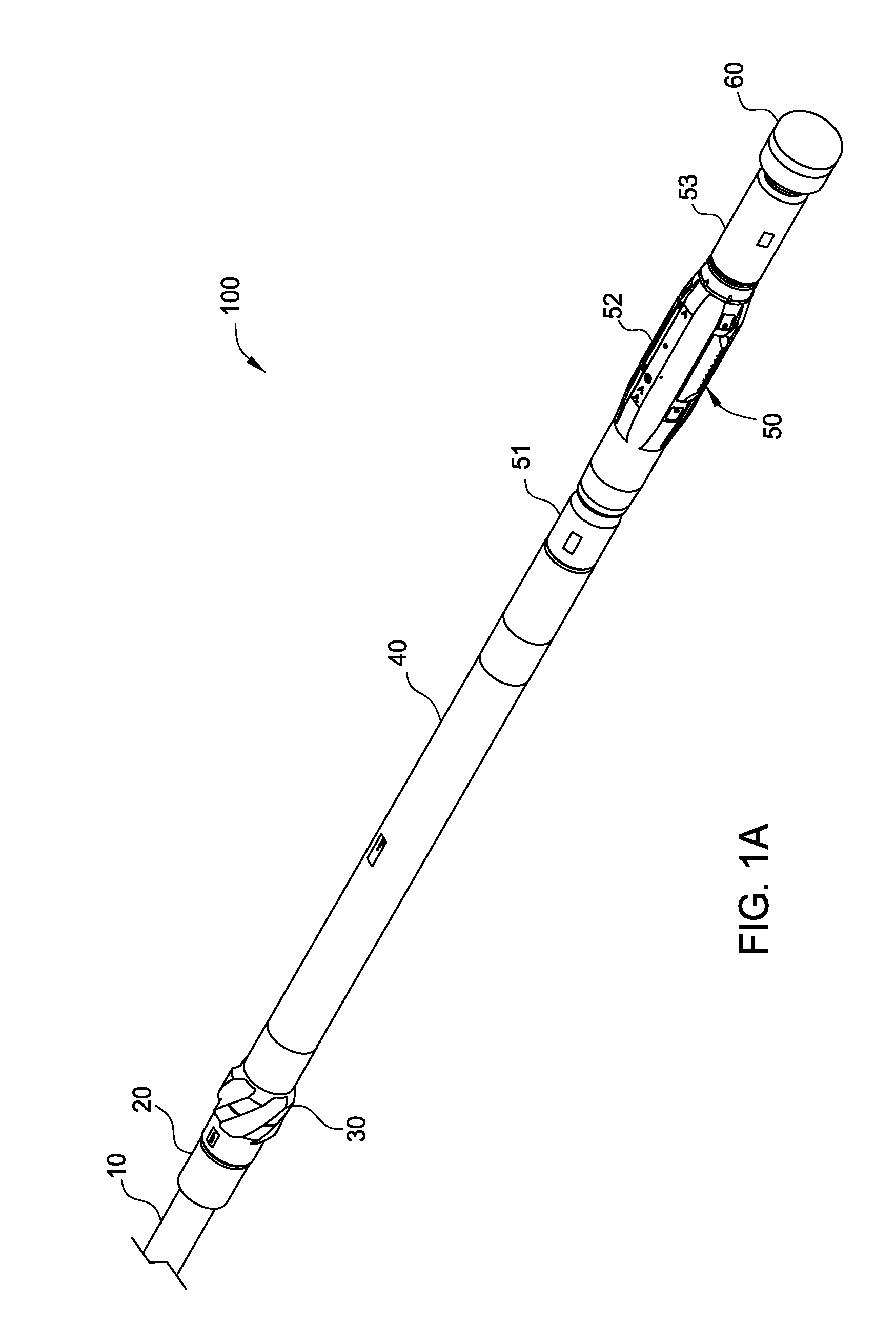

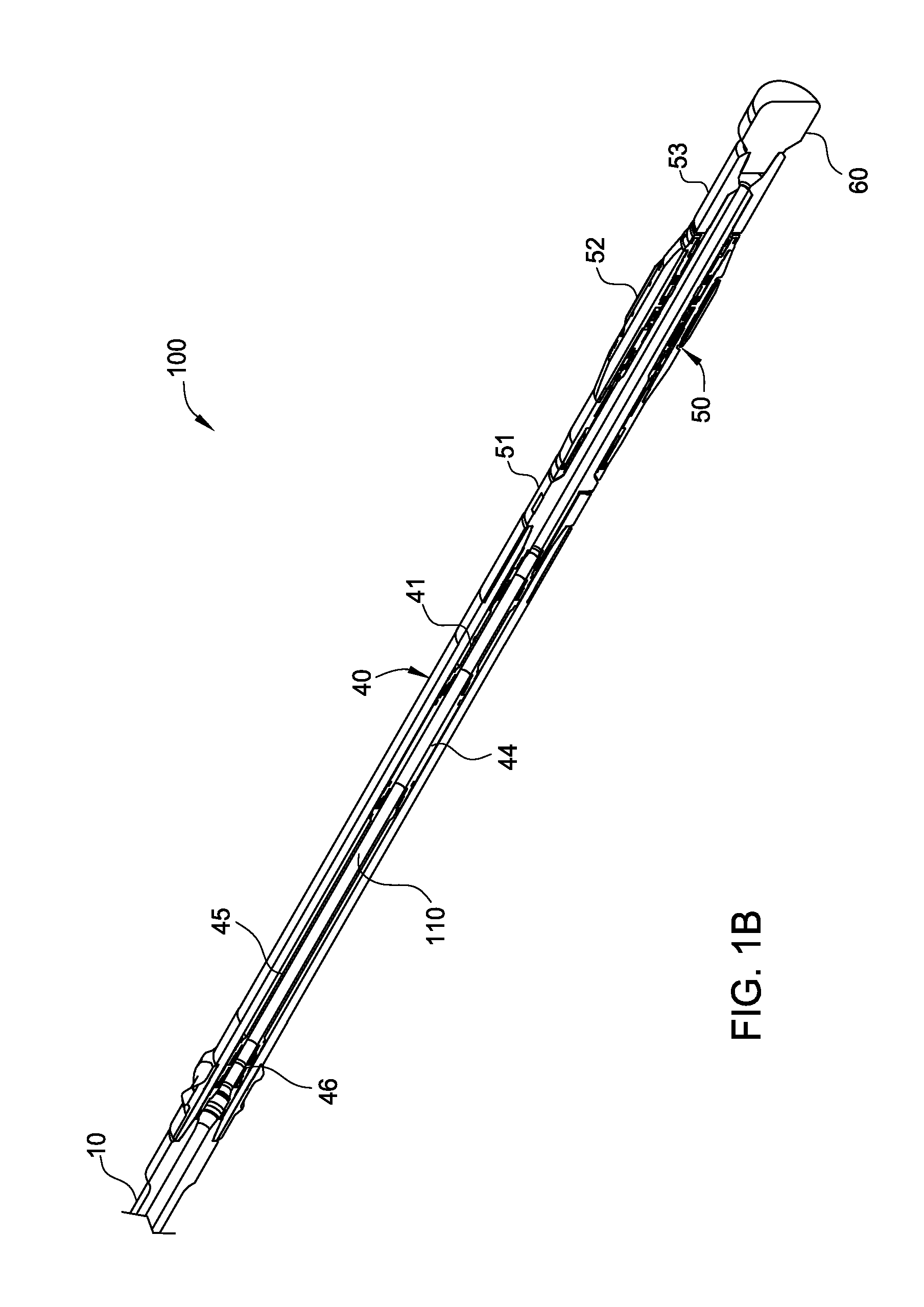

[0018]Embodiments of the invention relate to a rotary steerable drilling system for drilling wellbores. The system is operable to maintain a substantially vertical wellbore drilling path. If the system begins to deviate from the vertical drilling path (due to the wellbore formation characteristics for example), then the system is operable to automatically self correct and force the system back toward the vertical drilling path trajectory.

[0019]The system may be a self contained, electronically controlled, push bit system. The system may be rotated from the surface and / or may include conventional mud motors for providing additional rotational drill bit speed. The system may include one or more individually controllable and replaceable bias pads operable to force or push the drill bit in a desired direction. The bias pads may allow direction control of up to 5 percent over-gauge of the wellbore diameter. In the event of a failure, the system is designed to have a natural drop tendency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com