Controllable coolant pump having a fluidic actuator

a technology of fluidic actuator and controllable coolant pump, which is applied in the direction of engine control, engine cooling apparatus, mechanical apparatus, etc., can solve the problems of requiring a large installation space and the final control unit is heavy, and achieve the effect of reducing the weight and the necessary installation space of the controllable coolant pump, and in particular the internal combustion engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

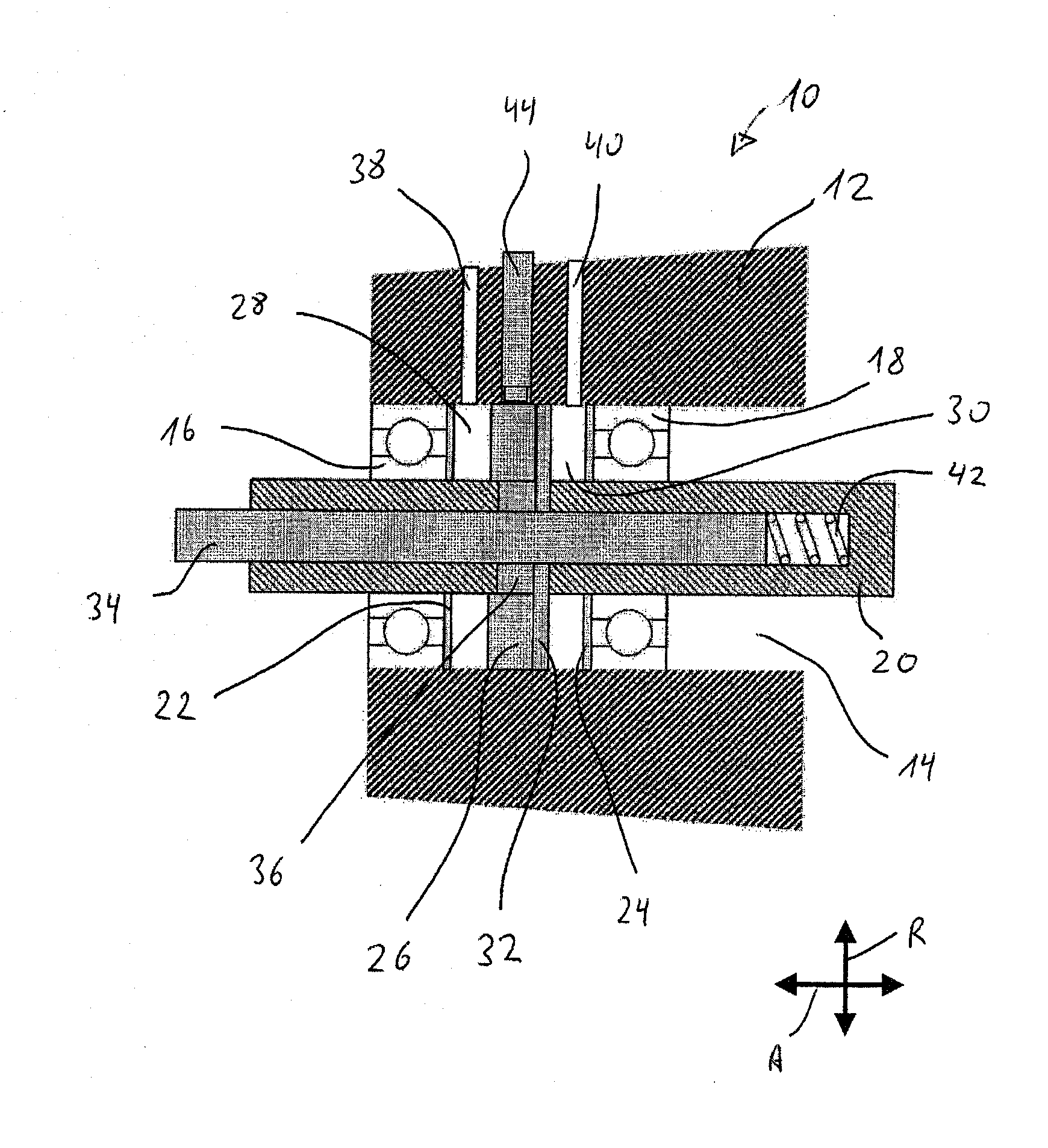

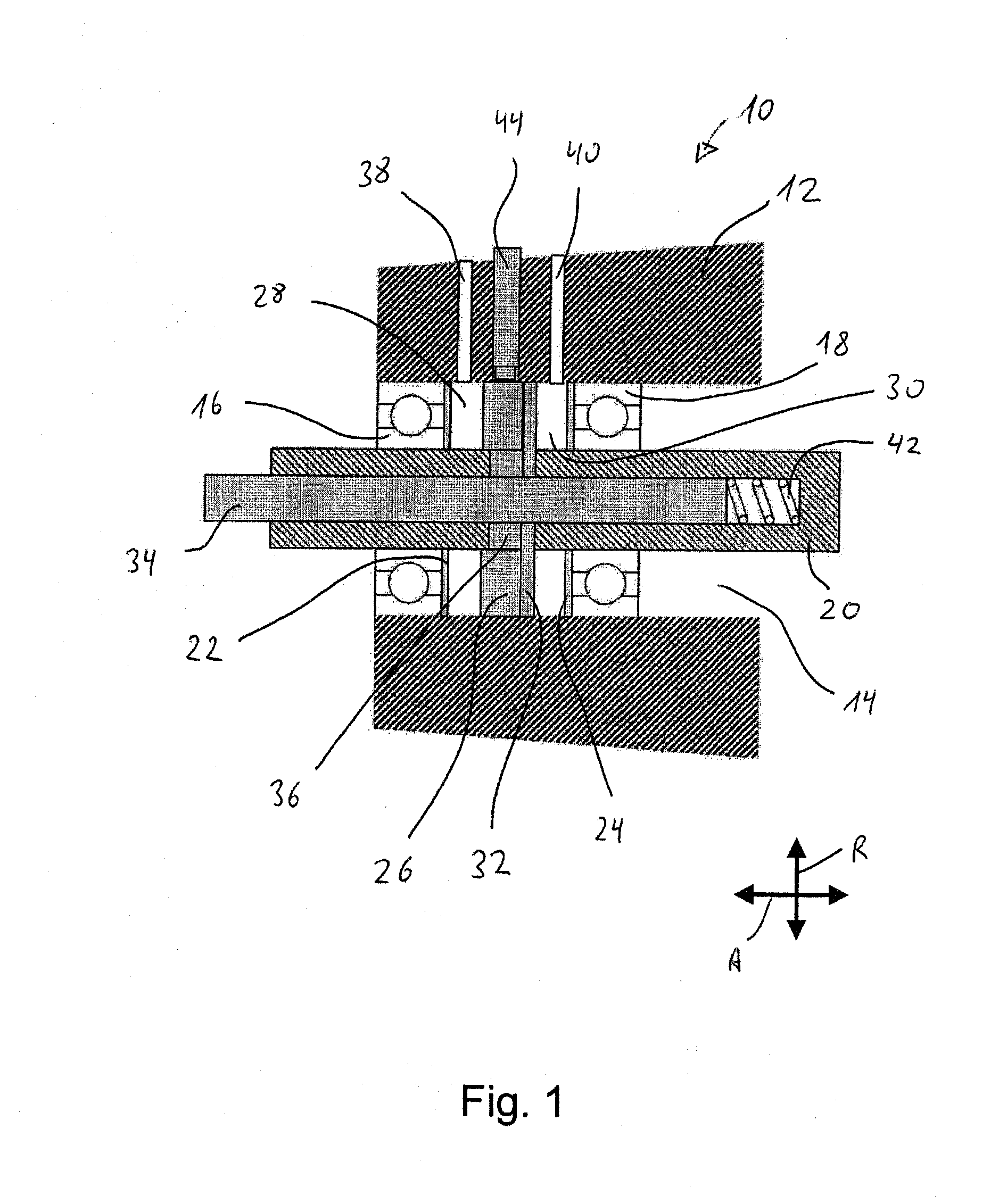

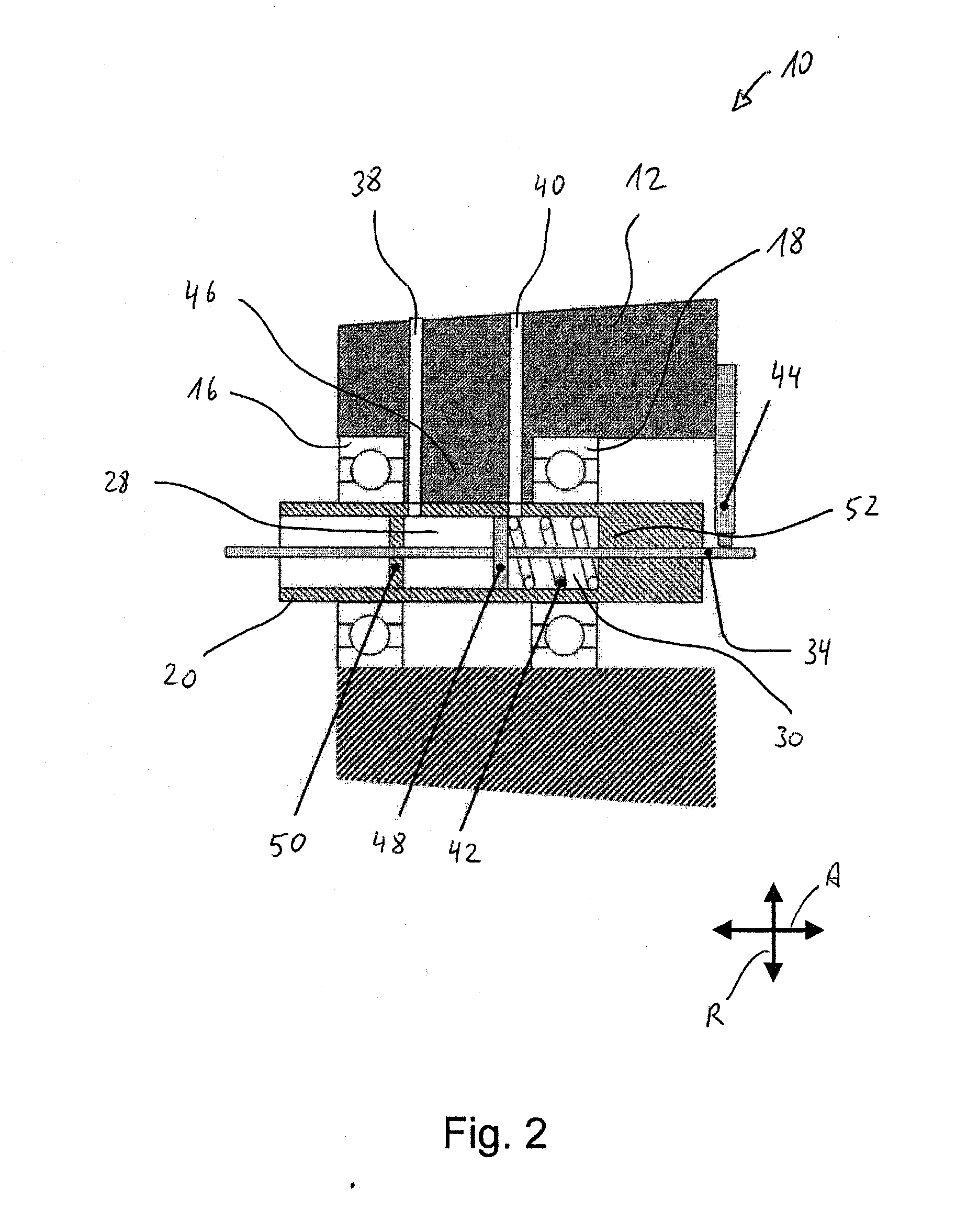

[0026]FIG. 1 shows a controllable coolant pump 10, which has a pump housing 12, including an inner bore 14. A first bearing 16 is situated within inner bore 14, and a second bearing 18 is situated at an axial distance therefrom. A shaft 20 is rotatably situated in first bearing 16 and second bearing 18 within inner bore 14 of pump housing 12. Between first bearing 16 and second bearing 18, an annular first seal 22 is situated on first bearing 16, and an annular second seal 24 is situated on second bearing 18. First seal 22 and second seal 24 form an essentially fluid-impermeable seal in the axial direction. A sealing ring 26, which is movably supported in the axial direction between first seal 22 and second seal 24, is situated between first bearing 16 and second bearing 18 and first seal 22 and second seal 24. A first pressure chamber 28, which is delimited in the radial direction by shaft 20 and pump housing 12, is provided between first seal 22 and sealing ring 26 in the axial di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com