Subnanometer catalytic clusters for water splitting, method for splitting water using subnanometer catalyst clusters

a technology of catalytic clusters and subnanometers, which is applied in the field of electrochemical reaction facilitation methods, can solve the problems of relatively low cost, achieve the effects of enhancing catalyst activity, reducing cost, and eliminating support structure defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

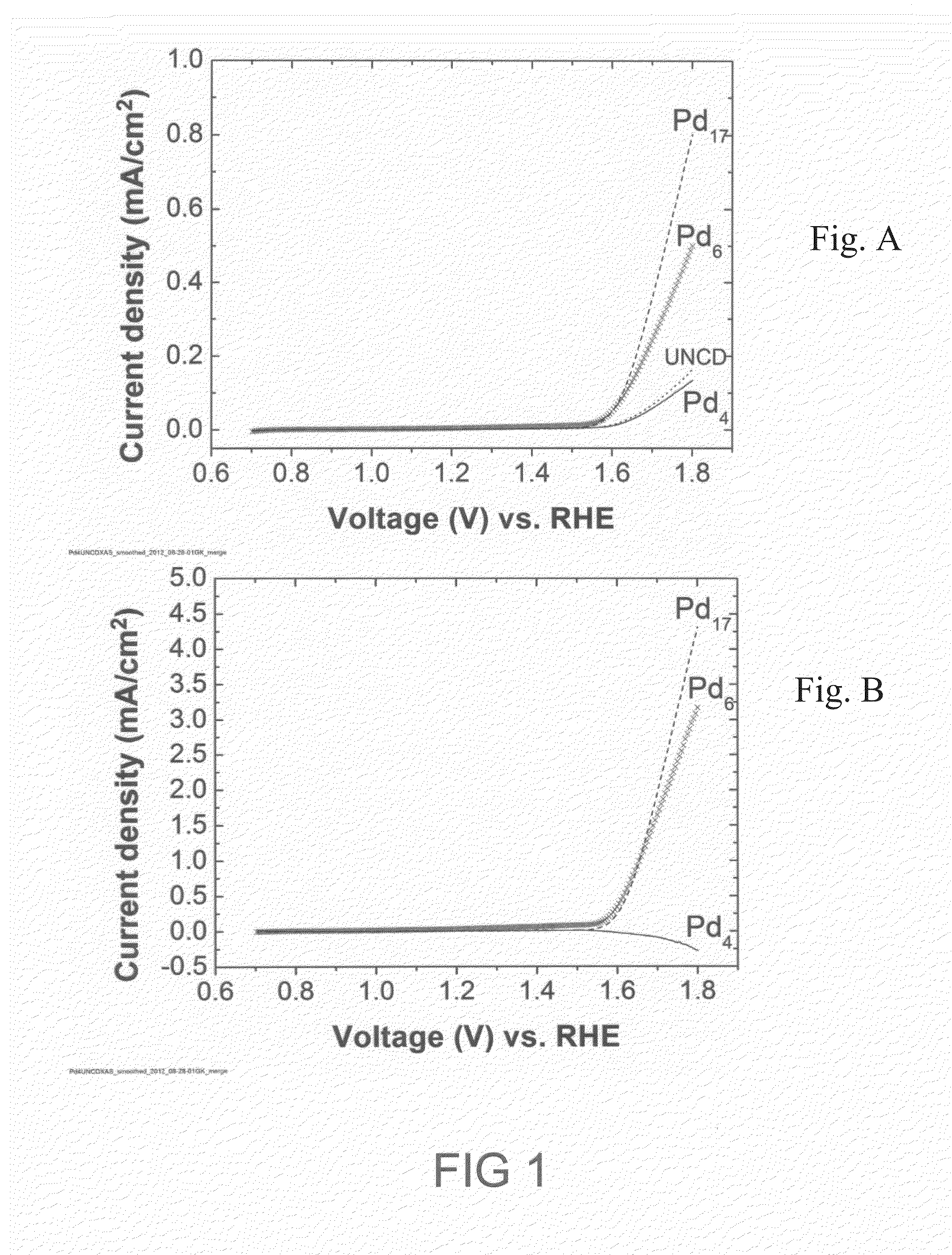

[0057]OER activity was measured for three Pd clusters (Pd4, Pd6 and Pd17). The activity was measured on an ultrananocrystalline diamond film electrode at pH 13.6 (1 M NaOH). FIG. 1a shows linear sweep voltammetry (LSV) curves of Pd4 (solid line), Pd6 (cross-hatched line) and Pd17 (dashed line) clusters after 500 second cleaning / preconditioning by chronoamperometry at about 1.7 V. A background curve (dotted line) for a UNCD coated electrode without deposited Pd clusters is also shown. The blank UNCD used was of the same dimensions and identical batch as the cluster-covered samples.

[0058]The graphs in FIGS. 1A and 1B depict large increases in anodic current between Pd6 or Pd17 clusters and the UNCD support. In this example, about 10 percent of the total surface area of the electrode was coated with Pd clusters, moreover within this area as low as 0.1 atomic monolayer equivalent of Pd metal (1.5×1014 atoms / cm2) was deposited. Generally, between about 1 and 25 percent of the surface are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com