Method, apparatus, and system used for purifying and silencing exhaust of internal combustion engine

a technology of internal combustion engine and exhaust gas, which is applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems of poor muffling effect of existing mufflers, poor ventilation conditions of two-stroke diesel engines, and often sparks from chimneys, so as to facilitate nox purification and release or reduce spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

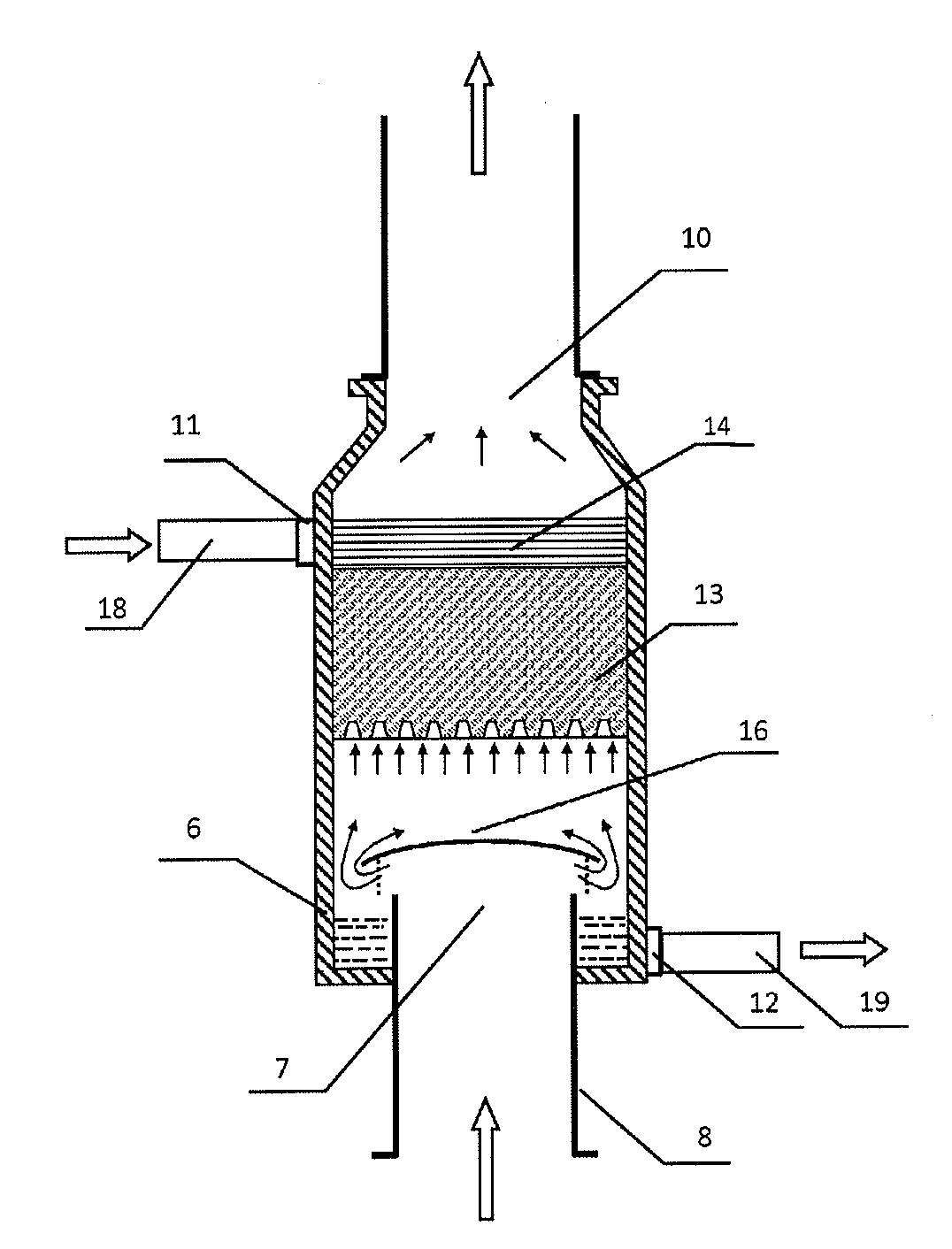

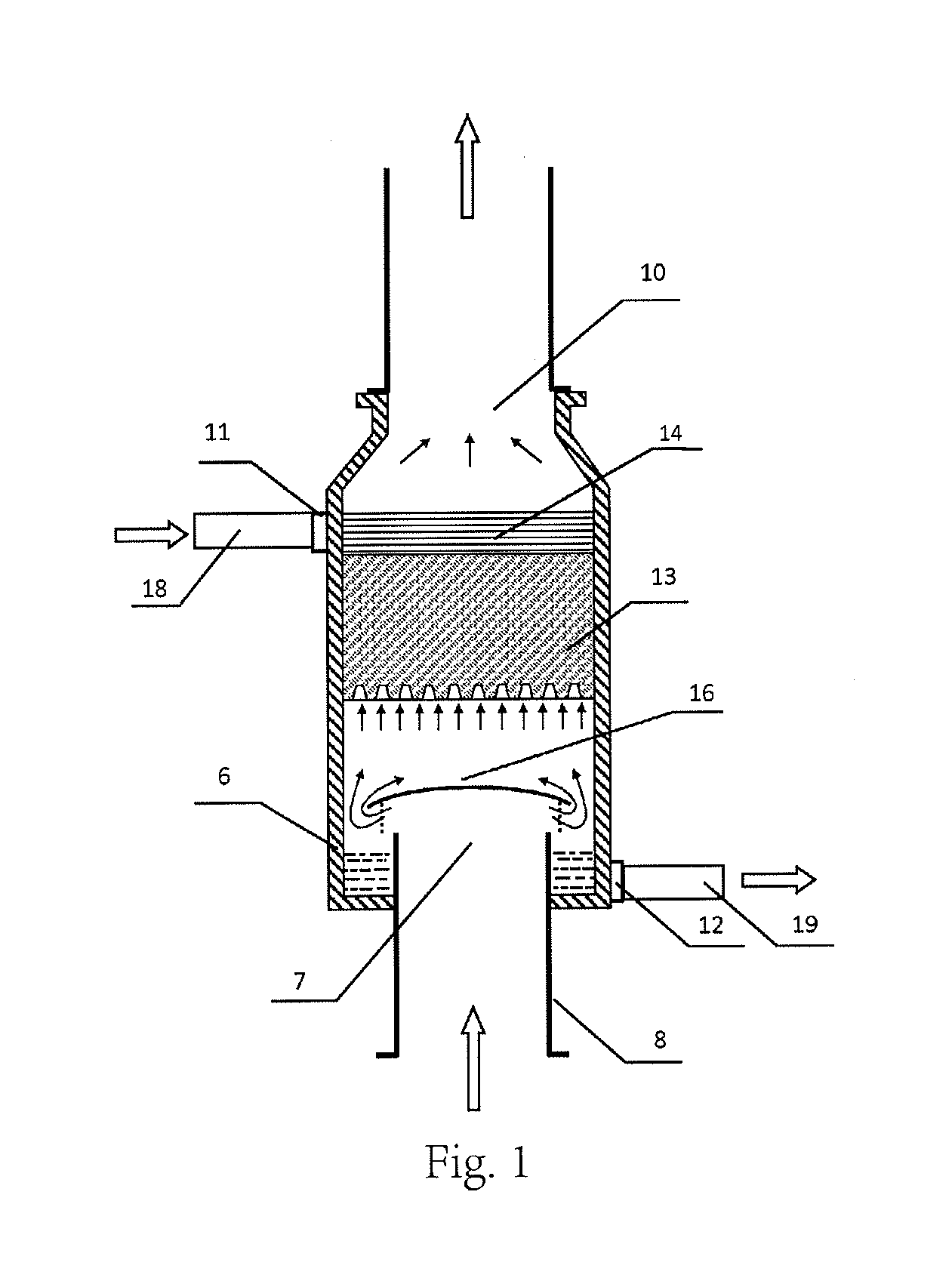

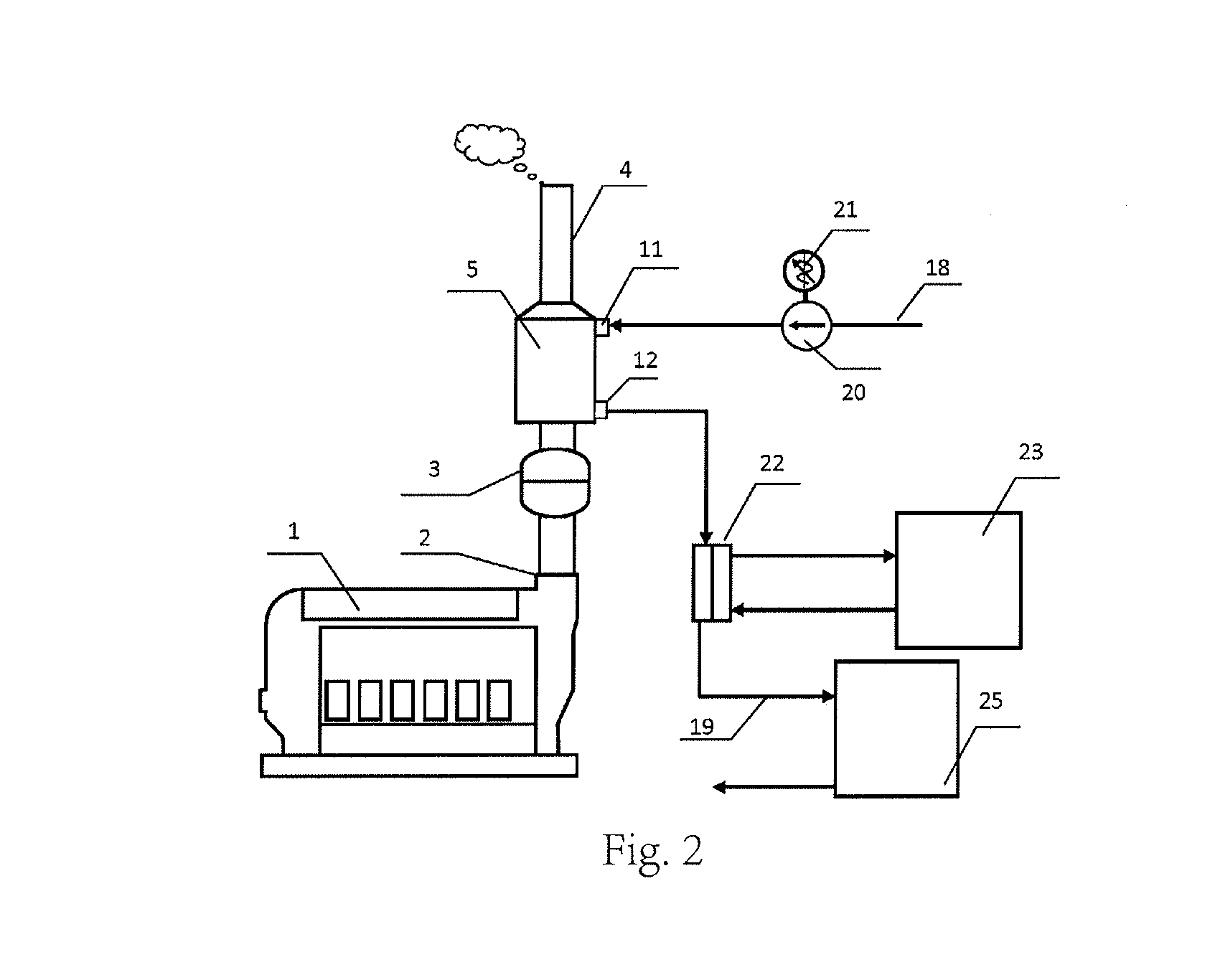

[0070]FIG. 1 and FIG. 2 show the device and system for purifying and muffling exhaust gas from an internal combustion engine according the present invention.

[0071]As shown in FIG. 1, the device for purifying and muffling exhaust gas from an internal combustion engine of the embodiment includes a housing 6 provided with a scrubbing water inlet 11 and a scrubbing water outlet 12, wherein the scrubbing water inlet 11 is located on the upper part of the side surface of the housing and the scrubbing water outlet 12 is located on the lower part of the side surface of the housing. Under the gravity effect, the seawater entering the housing via the scrubbing water inlet 11 passes through from top to bottom and is discharged via the scrubbing water outlet 12.

[0072]The housing is also provided with an exhaust gas inlet pipe 8 and an exhaust gas outlet 10, wherein the exhaust gas inlet pipe 8 extends into the interior of the housing, and the pipe orifice extending to the inside of the housing ...

second embodiment

[0081]FIG. 3 shows the device for purifying and muffling exhaust gas from an internal combustion engine according to the present invention.

[0082]Different from the device for purifying and muffling exhaust gas from an internal combustion engine of the first embodiment, the exhaust gas inlet 7 of the device for purifying and muffling exhaust gas from an internal combustion engine in this embodiment is located at the lower part of the side surface of the housing 6. In a gravity direction, the position of the exhaust gas inlet 7 is higher than the position of the scrubbing water outlet 12. In this case, the exhaust passage of the internal combustion engine communicates with the side surface of the housing via the exhaust gas inlet pipe 8. Since the exhaust gas enters from the side surface of the housing, a water baffle is unnecessary. The scrubbing water of the present embodiment reuses the engine cooling water.

[0083]The exhaust passage of the internal combustion engine communicates wi...

third embodiment

[0084]FIG. 4 and FIG. 5 show the device and system for purifying and muffling exhaust gas from an internal combustion engine of the present invention.

[0085]Different from the device for purifying and muffling exhaust gas from an internal combustion engine of the first embodiment, in this embodiment, a cooling pipeline 17 is provided in the housing of the device for purifying and muffling exhaust gas from an internal combustion engine, i.e. the pipeline encapsulating the second cooling water. The cooling pipeline 17 is located below the water baffle 16, so that the scrubbing water does not fall onto the cooling pipeline 17, thereby producing high temperature steam. The inlet and outlet of the cooling pipeline 17 respectively extend out of the housing 6, and the inlet is higher than the outlet in the direction of gravity. When the device is installed, the inlet and outlet are connected to the pipeline transporting fluids. As a variation of this embodiment, the inlet and outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com