Process And Apparatus For The Separation Of Air By Cryogenic Distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

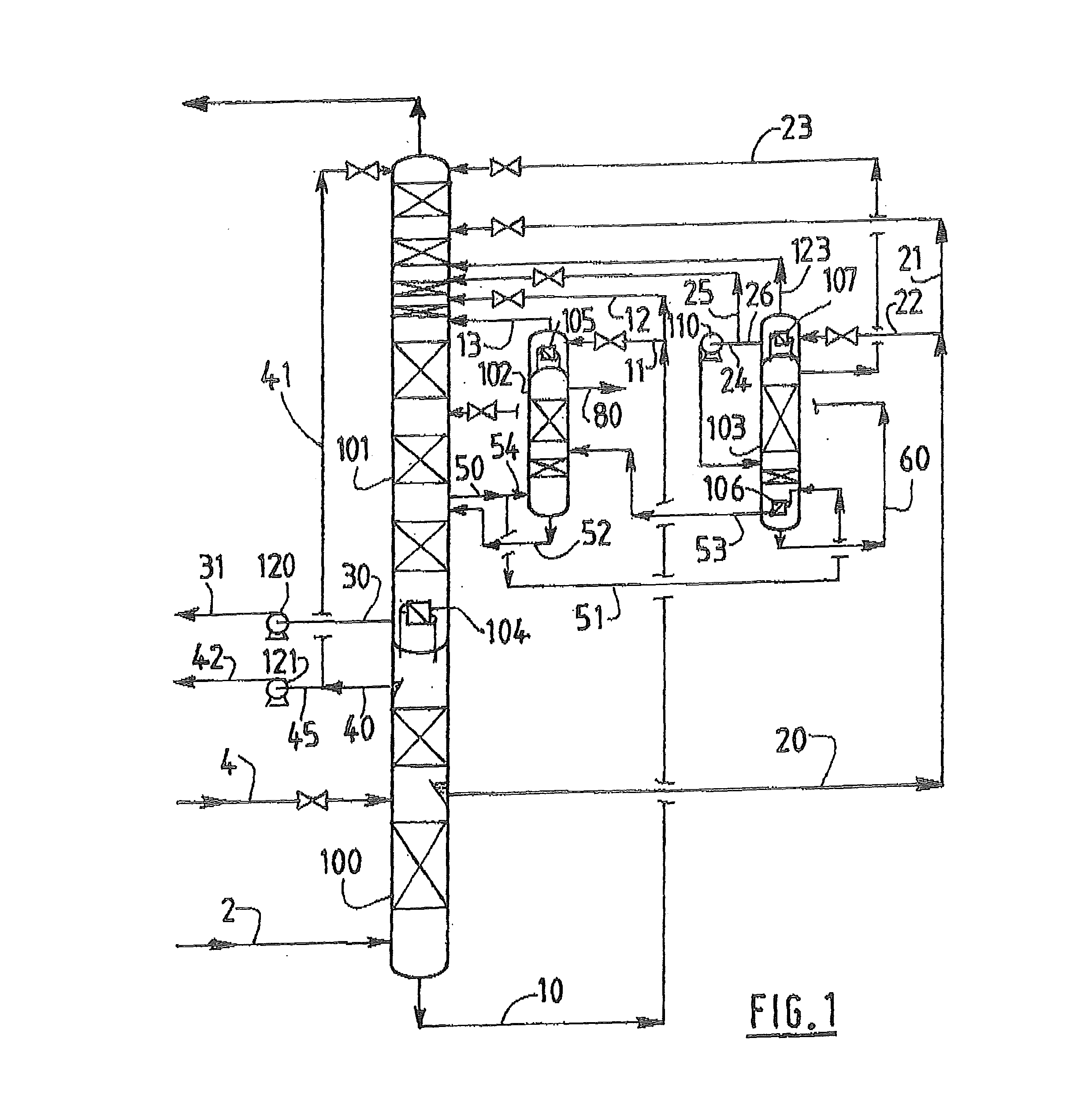

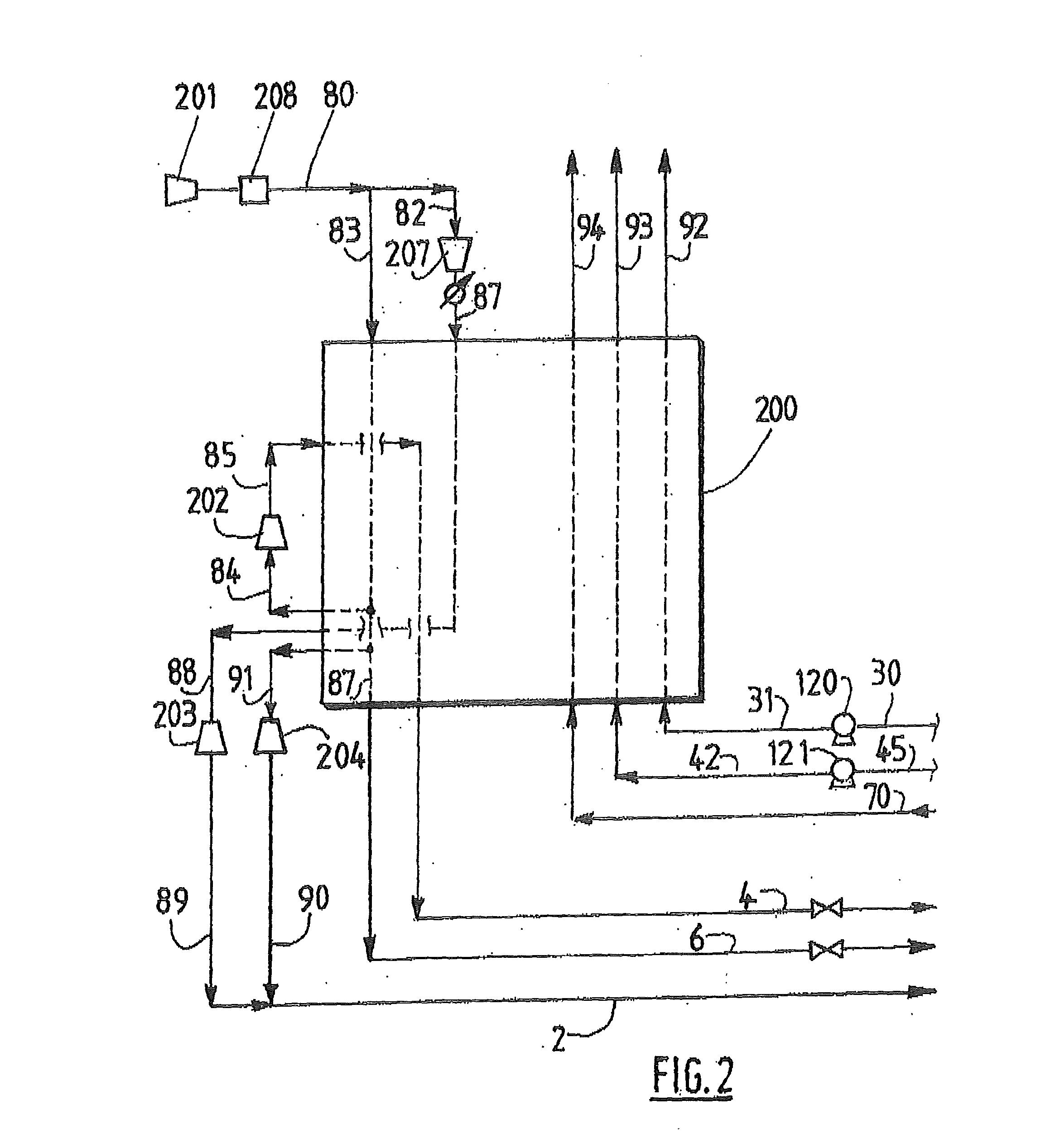

[0051]To illustrate the invention, FIG. 1 shows the column portion of a process operating according to an embodiment of the invention and FIGS. 2 and 3 show two alternative corresponding heat exchanger portions, to be used for oxygen pressures above 15 bars abs.

[0052]In FIG. 1, gaseous air 2 and liquid air 4 are fed to high pressure column 100. Oxygen enriched liquid 10 formed at the bottom of the high pressure column 100 is divided in two. One portion 12 is expanded and sent to an intermediate level of the low pressure column 101. Another portion 11 is expanded and sent to top condenser 105 of the argon column where it vaporizes to form stream 13 which is sent to the low pressure column 101. Alternatively all the oxygen enriched liquid 10 can be sent to the condenser 105 and partially condensed. In this case, stream 12 is absent and liquid from condenser 105 is sent to the low pressure column 101. The top of the high pressure column 100 is thermally coupled to the bottom of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com