Roll-to-roll electrochemical polish apparatus

a technology of electrochemical polishing and rolling to roll, which is applied in the direction of electrolysis components, manufacturing tools, electrolysis processes, etc., can solve the problems of hard to acquire zirconia, affecting the quality of products made by metal foils, and affecting the production cost reduction of metal foils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

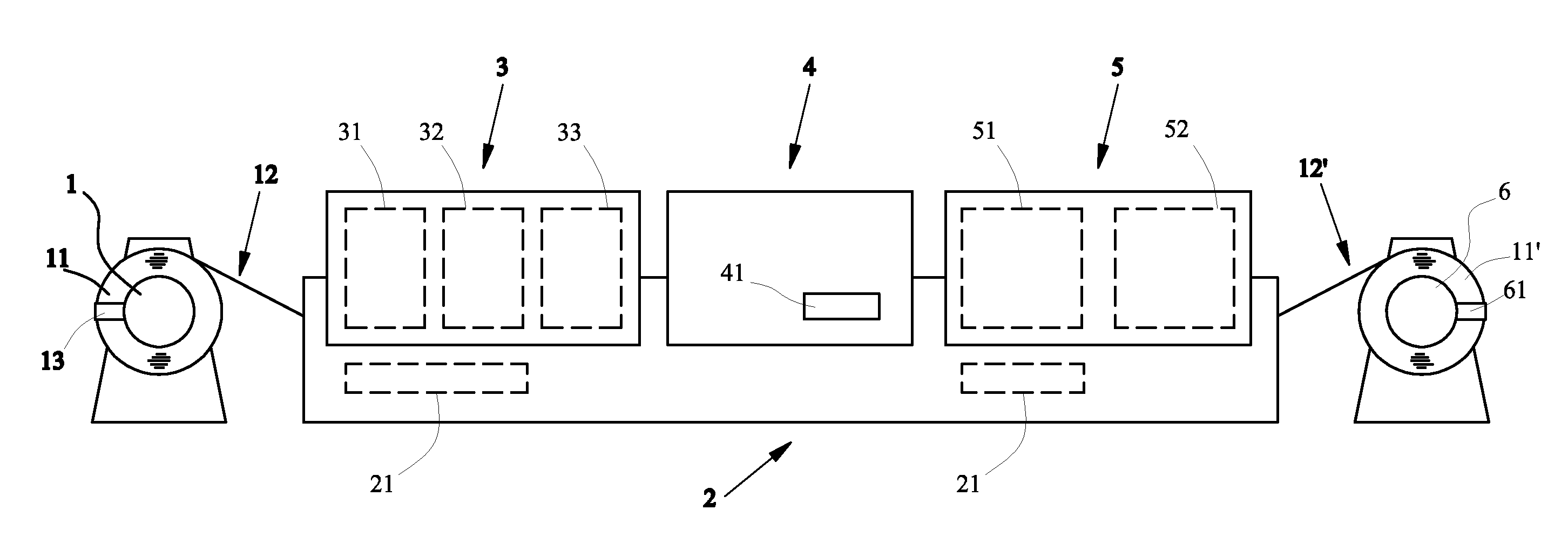

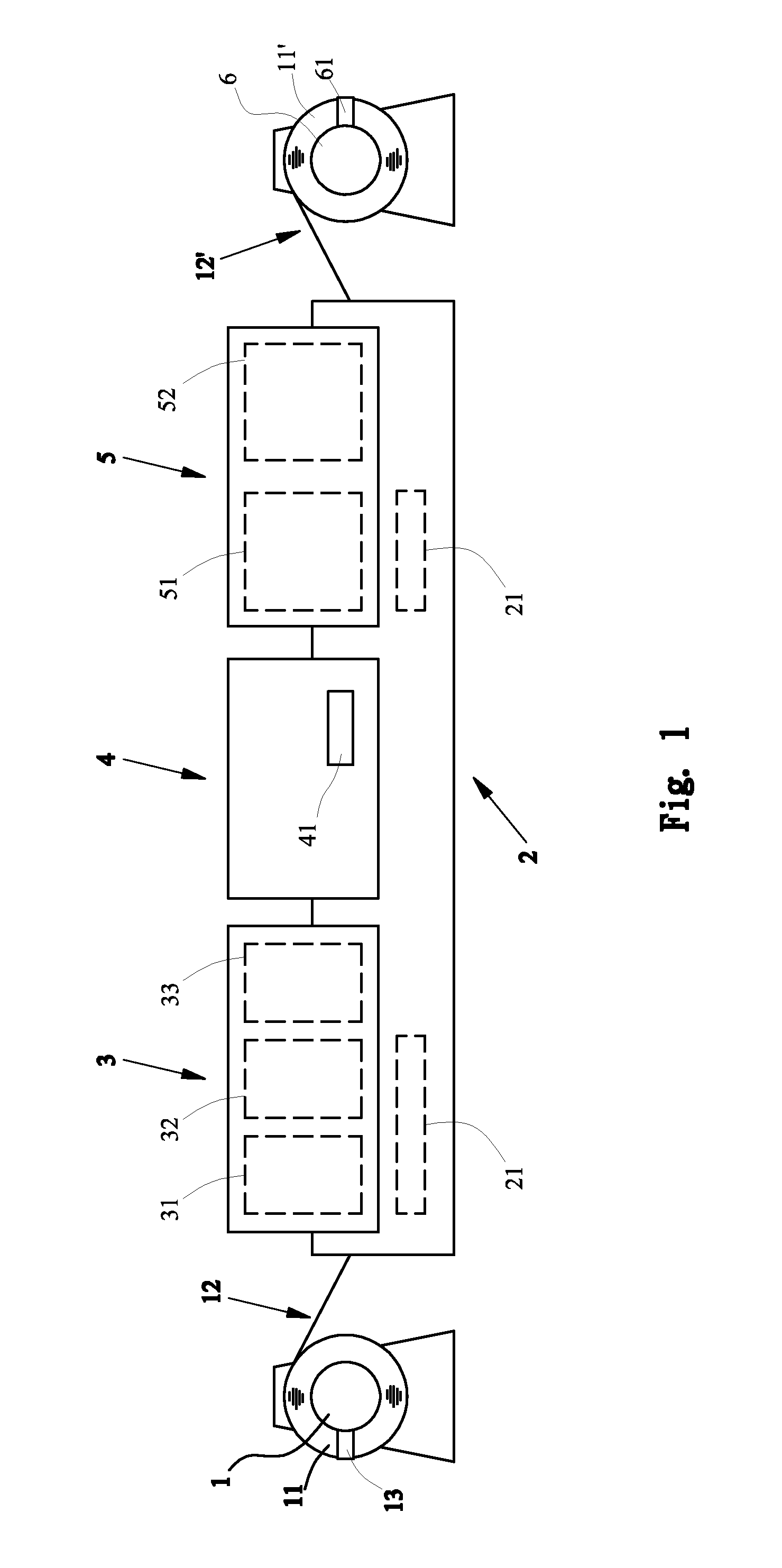

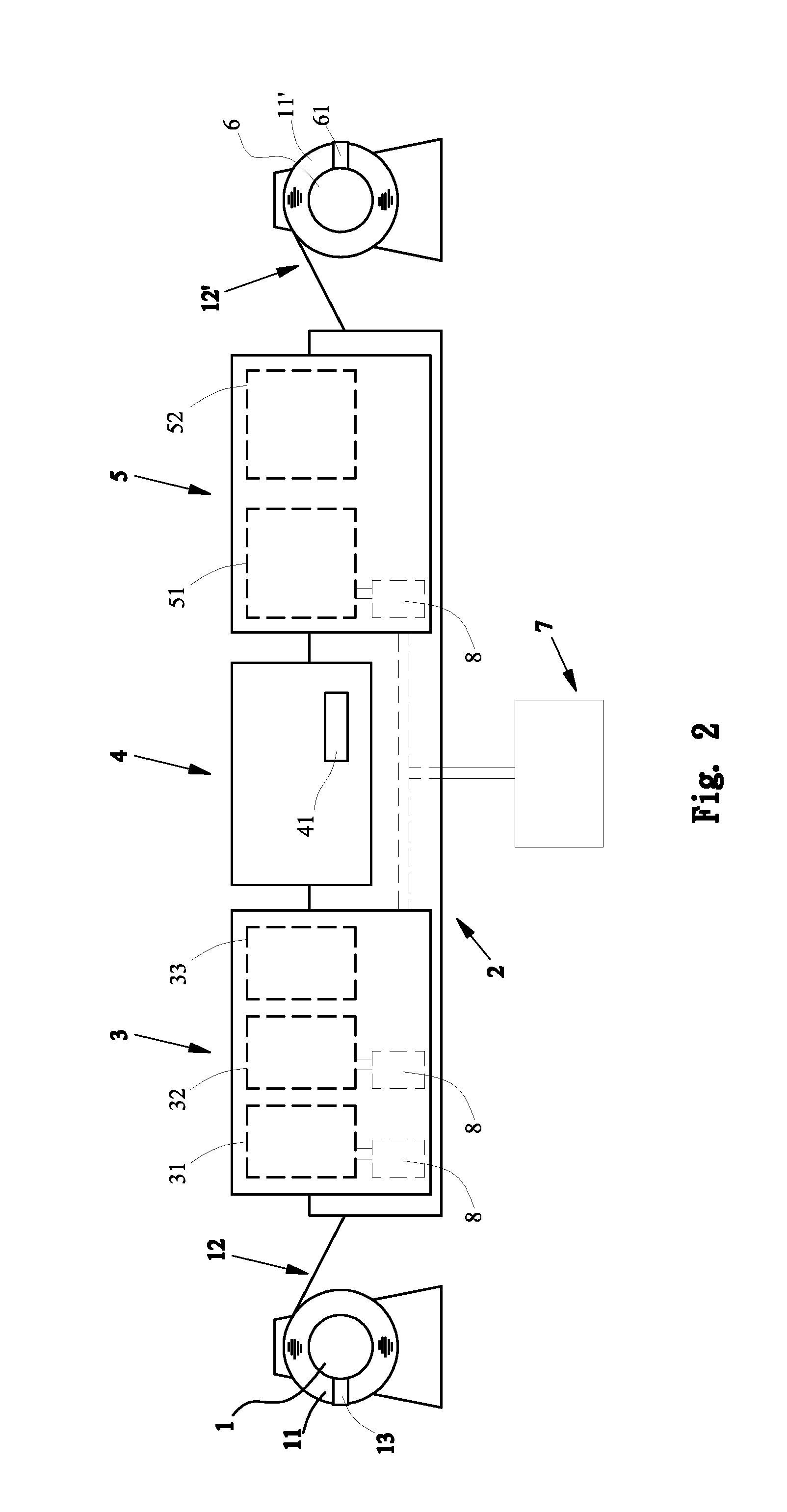

[0014]With reference to FIG. 1, a first embodiment of an electrochemical polish apparatus in accordance with the present invention has a first rotator 1, a transporting device 2, a pre-treatment device 3, an electrochemical polish device 4, a post-treatment device 5 and a second rotator 6.

[0015]The first rotator 1 serves to load a metal foil roll 11, is driven by a motor, which provides a power to steadily rotate the metal foil roll 11, such that a metal foil 12 of the metal foil roll 11 can be spread out. The first rotator 1 has a holder 13 mounted on the first rotator 1 for the metal foil roll 11 to be held by the holder 13 and keeps the metal foil 12 to be spread out in a right direction.

[0016]The transporting device 2 serves to deliver the metal foil 12, provides a conveying path for the metal foil 12, and one end of the conveying channel receives the metal foil 12 from the metal foil roll 11. The transporting device 2 has two ultrasound generators 21 respectively embedded in tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com