False eyelashes and manufacturing method therefor

a manufacturing method and eyelash technology, applied in the field of false eyelash structure, can solve the problems of time-consuming process, difficult handling of eyelash extensions, thin and small, etc., and achieve the effects of excellent processibility, economic feasibility, and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

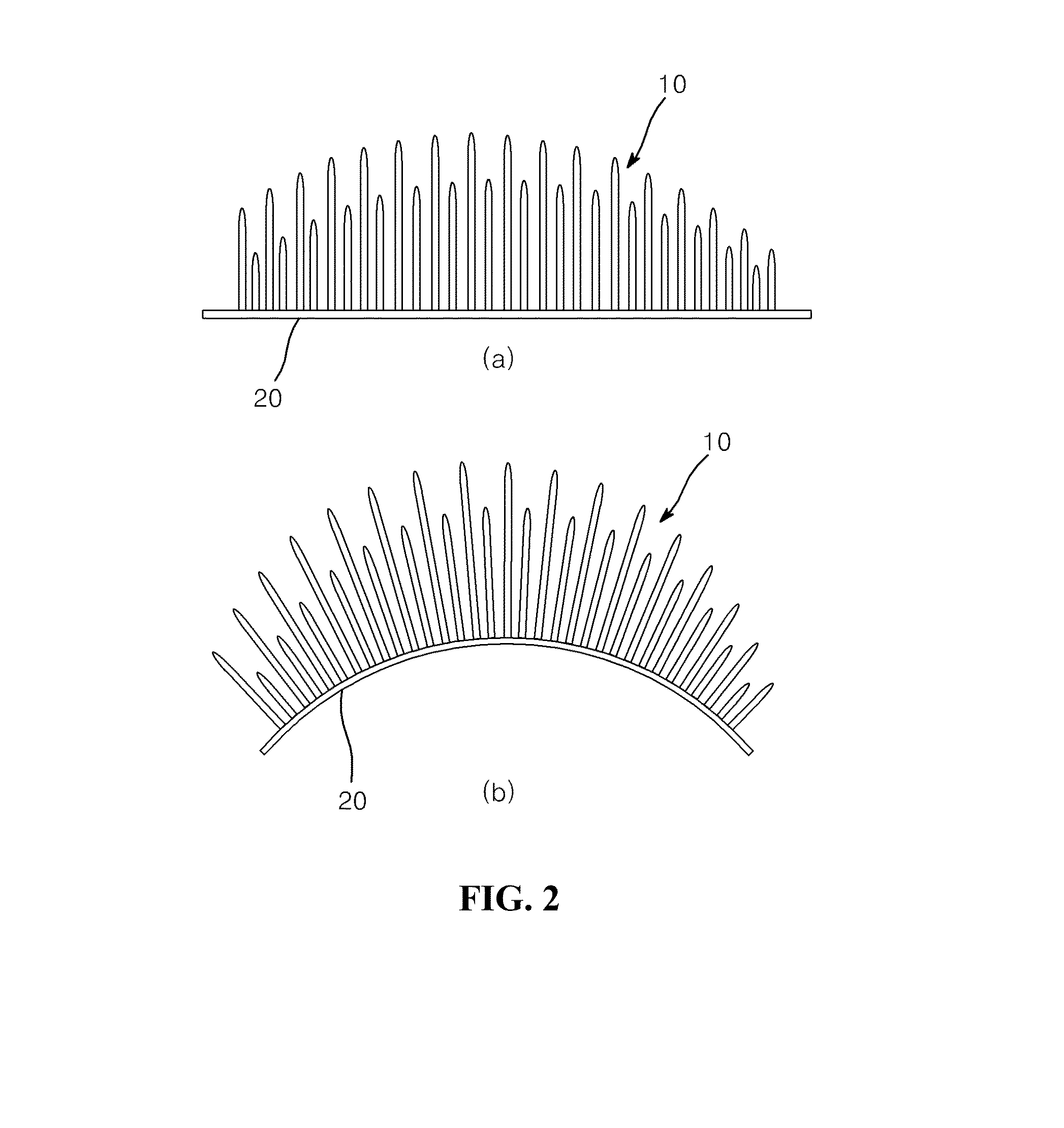

[0066]FIG. 5 is a picture of false eyelash structures having various shapes manufactured through the method according to the present invention. The method according to the invention provides excellent processibility, excellent economic efficiency and uniform quality in manufacture of false eyelash structures, and the false eyelash structures manufactured by the method have excellent properties in terms of shape stability and elasticity.

[0067]FIG. 6 shows a method of manufacturing a false eyelash structure according to another embodiment of the present invention. In this embodiment, two false eyelash structures manufactured by injection molding according to the invention may be coupled to each other such that an artificial hair part can be realized in various ways.

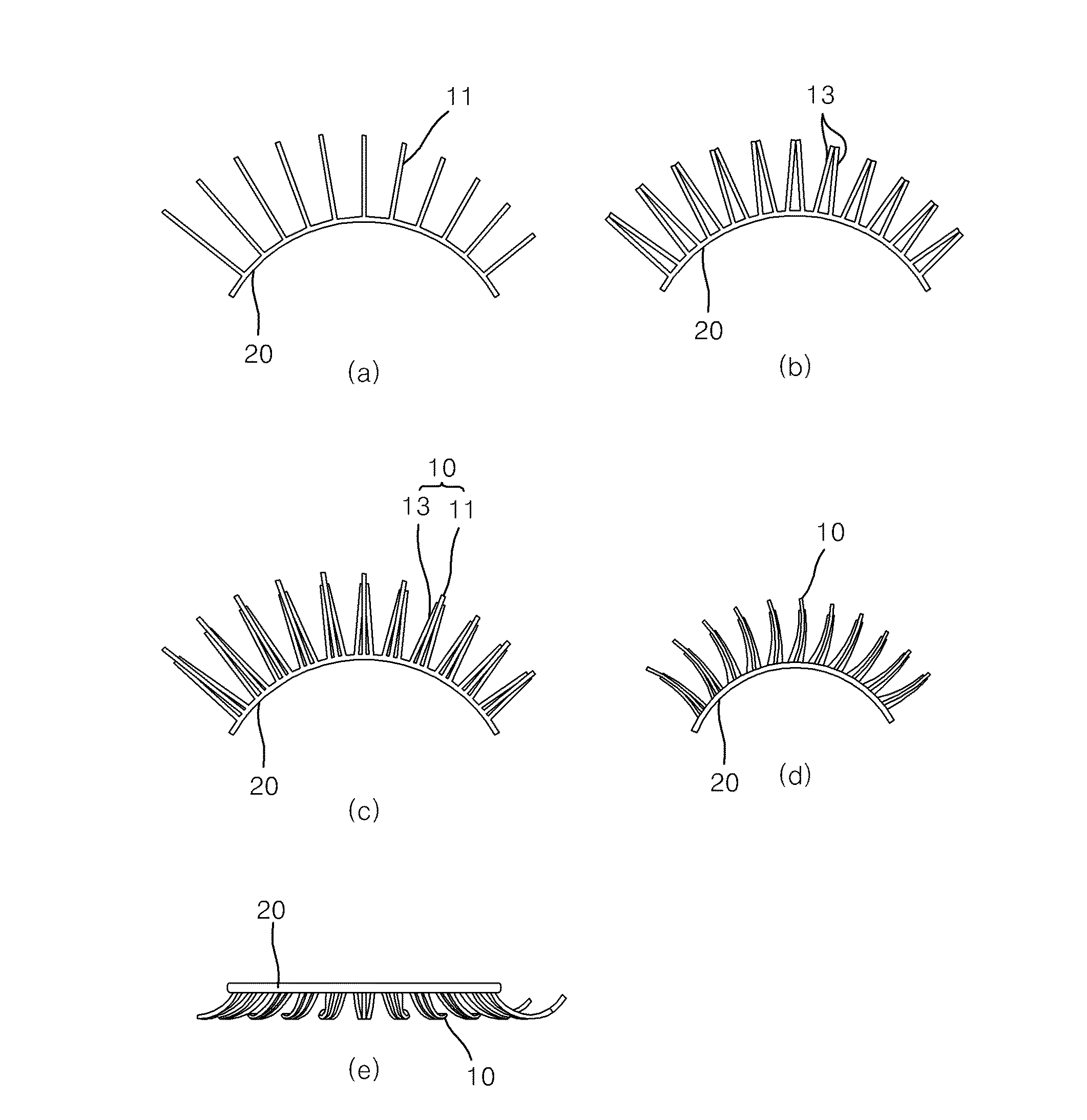

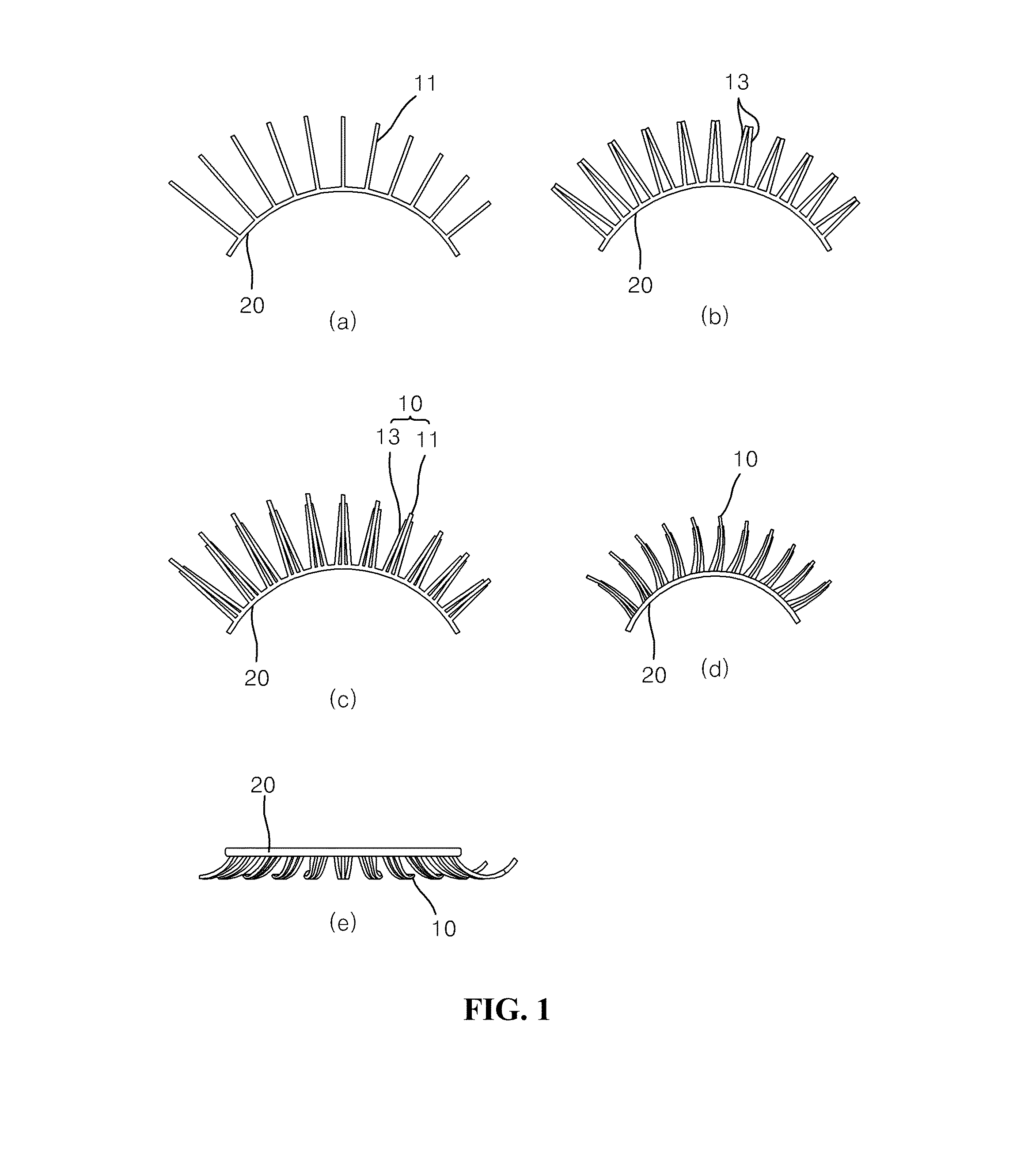

[0068]FIGS. 7(a) to 7(c) show false eyelash structures according to other embodiments of the present invention. The false eyelash structures having artificial hair parts whose shapes are complex can be repeatedly manufactur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com