Magnetic memory including memory cells incorporating data recording layer with perpendicular magnetic anisotropy film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

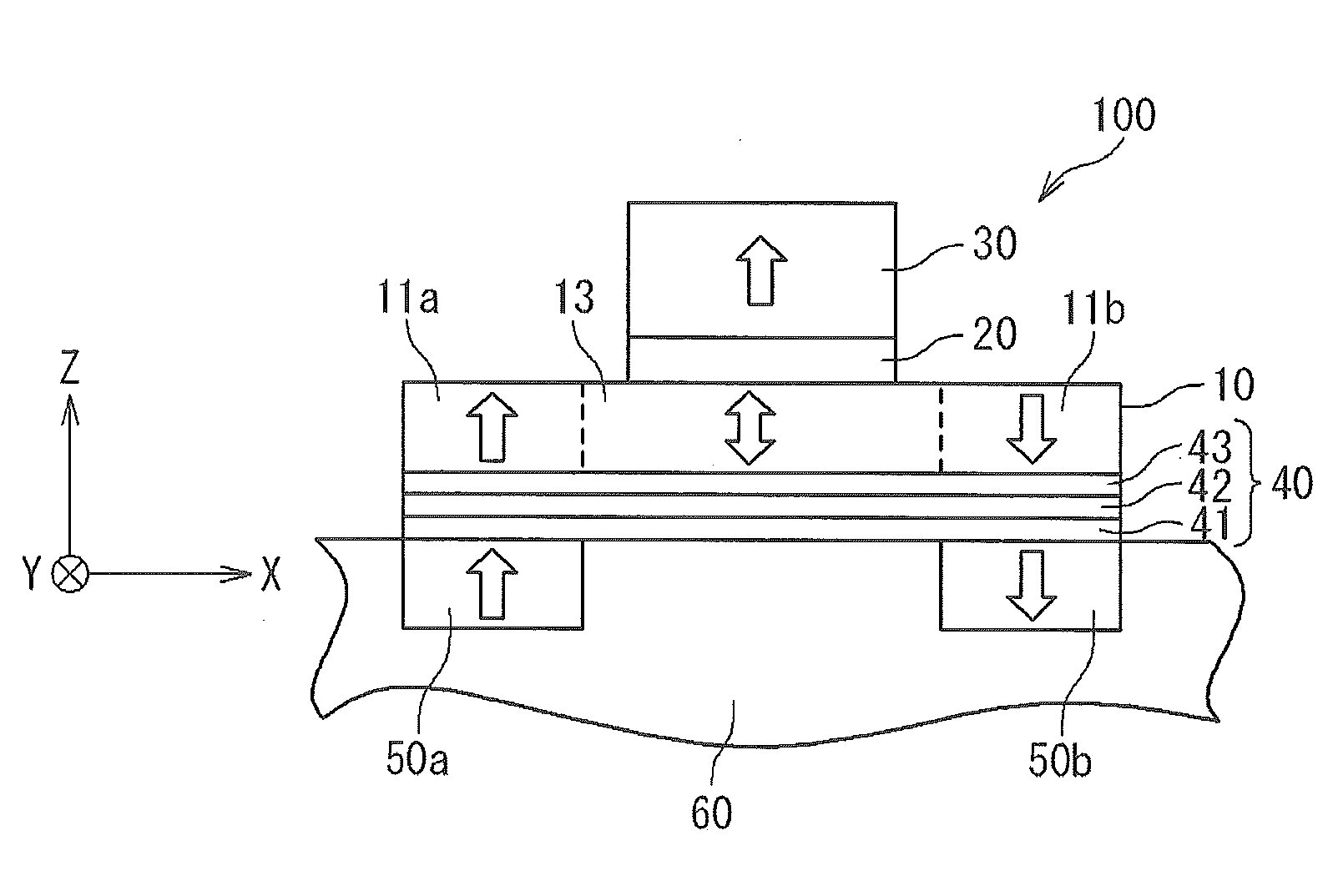

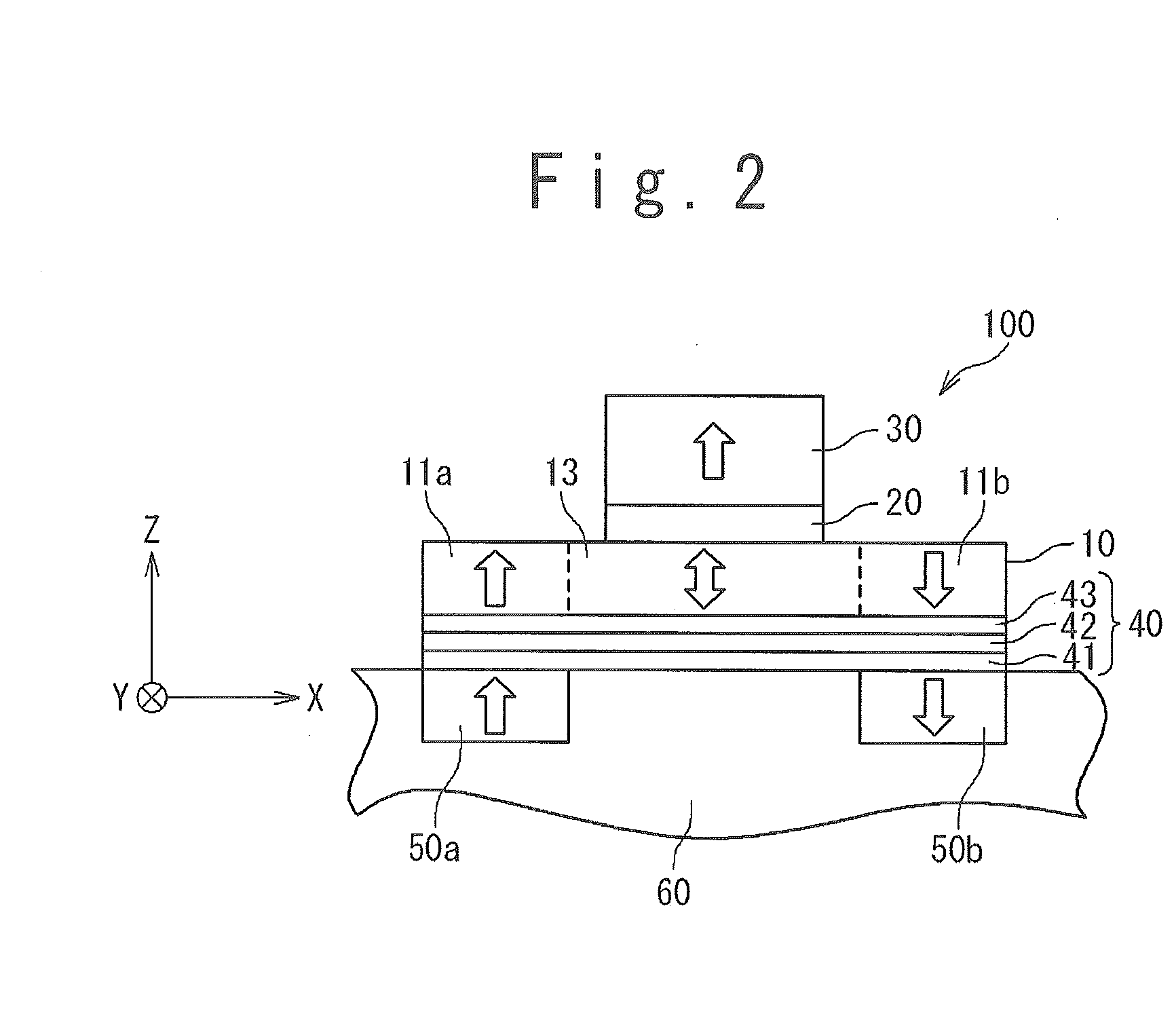

[0071]FIG. 2 is a section view schematically showing an exemplary configuration of a magnetoresistance element 100 in a first embodiment of the present invention. The magnetoresistance effect element 100 includes a data recording layer 10, a spacer layer 20, a reference layer 30, an underlayer 40 and magnetization fixed layers 50a and 50b.

[0072]The data recording layer 10 is formed of ferromagnetic material with perpendicular magnetic anisotropy. The data recording layer 10 includes a region in which the magnetization direction is reversible and stores data as the magnetization state thereof. In detail, the data recording layer 10 includes a pair of magnetization fixed regions 11a and 11b and a magnetization free region 13.

[0073]The magnetization fixed regions 11a and 11b are disposed adjacent to the magnetization free region 13. The magnetizations of the magnetization fixed regions 11a and 11b are fixed in opposite directions (or in antiparallel). In the example shown in FIG. 2, t...

second embodiment

[0138]FIG. 12 is a section view showing an exemplary structure of a magnetoresistance effect element 100A of a second embodiment of the present invention. The magnetoresistance effect element 100A of the second embodiment is structured similarly to the magnetoresistance effect element 100 of the first embodiment. The difference exists in the structure of the underlayer. In the first embodiment, as described above, the first magnetic underlayer 41 in the underlayer 40 is formed of material which is intrinsically ferromagnetic with such a thin thickness that the first magnetic underlayer 41 does not exhibit ferromagnetism. In the second embodiment, on the other hand, a first magnetic underlayer 41A in an underlayer 40A is formed of material which intrinsically exhibits in-plane magnetic anisotropy, but with such a thin thickness (specifically, 0.5 to 3 nm) that the first magnetic underlayer 41A exhibits perpendicular magnetic anisotropy. The first magnetic underlayer 41A is formed of ...

experiment 1

Dependence of MR ratio of Magnetic Tunnel Junction on Material of Underlayer

[0144]Examined first was the dependence of the MR ratio of the magnetic tunnel junction composed of the data recording layer 10, the spacer layer 20 and the reference layer 30 on the material of the first magnetic underlayer 41 or 41A. For each magnetoresistance effect element, a dielectric film corresponding to the interlayer dielectric 60 was formed on a substrate and the underlayer 40 or 40A, the data recording layer 10, the spacer layer 20, and the reference layer 30 were formed. As the underlayer 40 or 40A, the first magnetic underlayer 41 or 41A, the non-magnetic underlayer 42 and the second magnetic underlayer 43 were serially formed in this order.

[0145]A NiFeZr film, a CoTa film, a CoZr film or a FeZr film having a thickness of 1.5 nm was used as the first magnetic underlayer 41 or 41A. The NiFeW film included 12.5 atomic % tungsten (W) and the remainder was NiFe base metal. The ratio of Ni to Fe in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com