Solid-Wood Rigid Block Assemblies

a technology of solid-wood rigid blocks and blocks, applied in the field of solid-wood rigid block assemblies, can solve the problems of difficult manufacturing, relatively easy manufacturing, and inferior reliability and durability of engineered wood products, and achieve the effects of improving reliability and durability, reducing production costs, and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

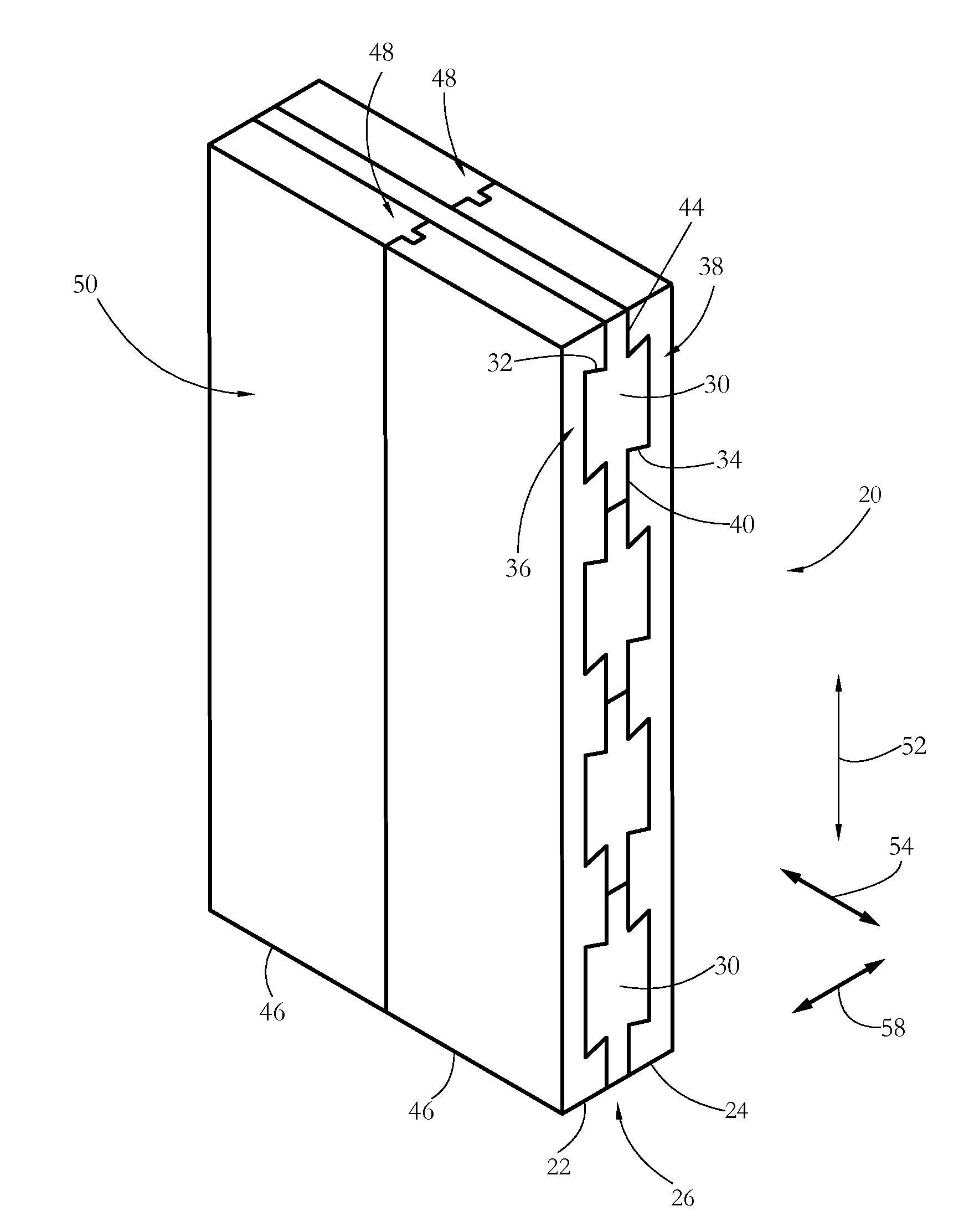

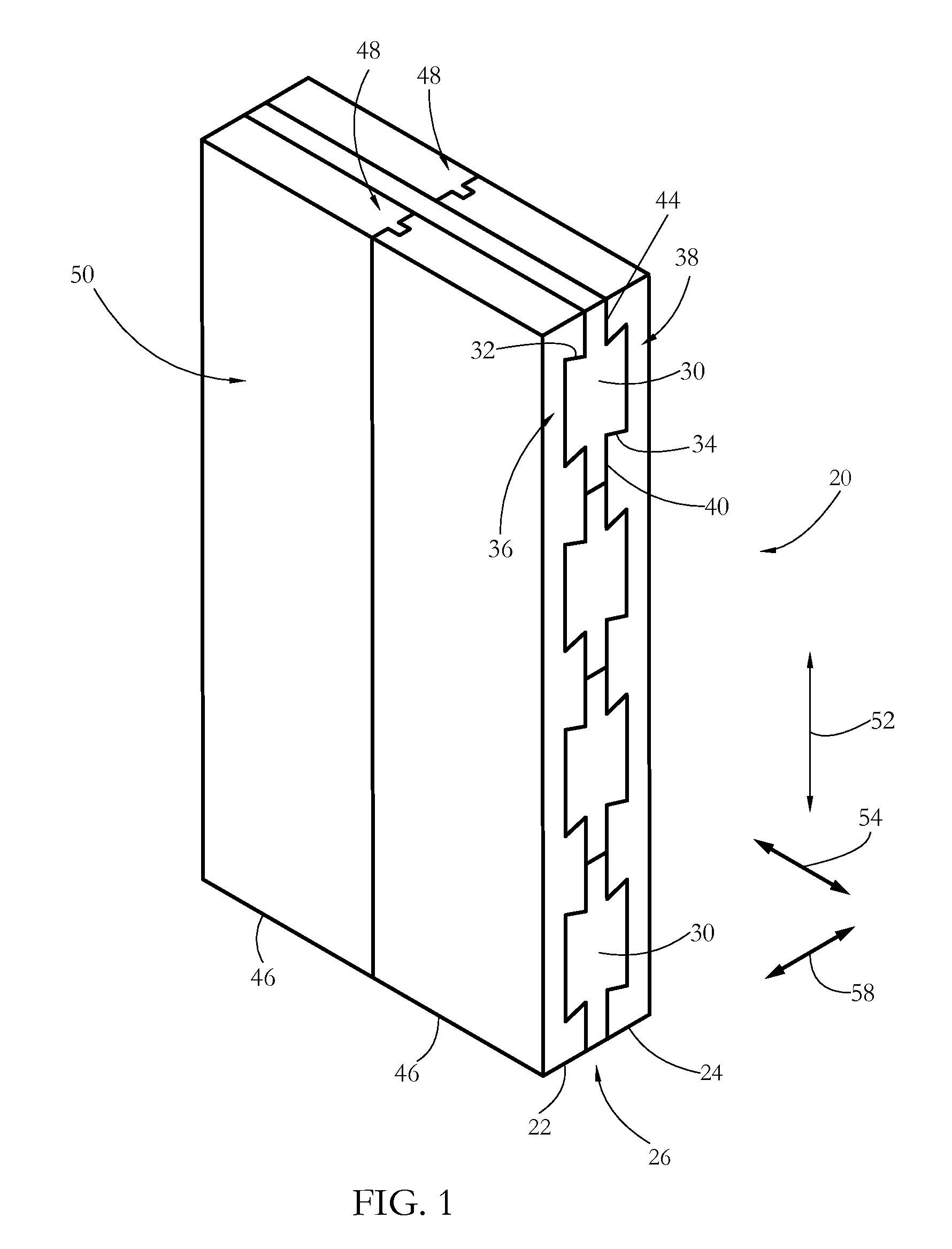

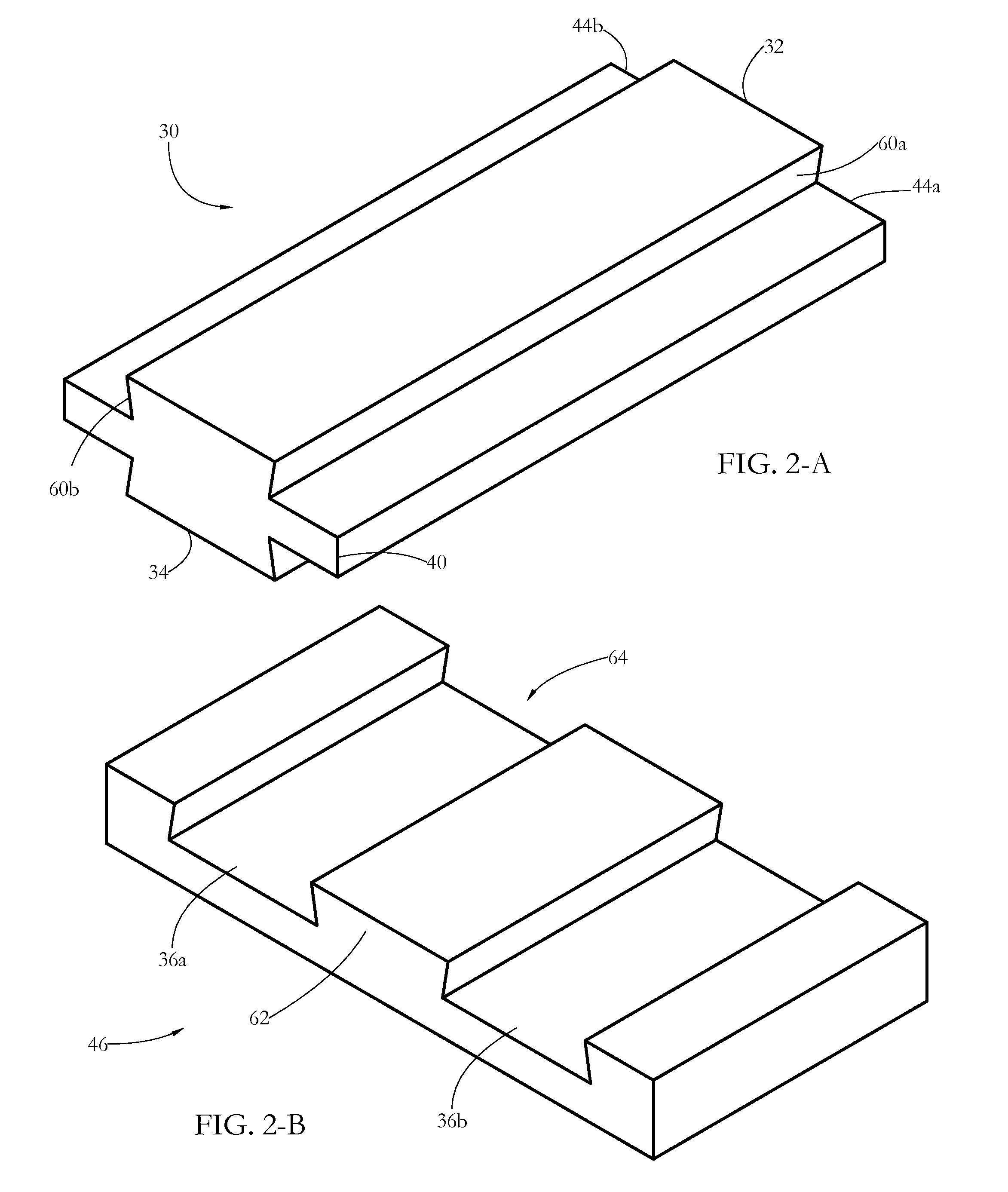

[0017]The following description illustrates the present invention by way of example and not necessarily by way of limitation. A set of elements includes one or more elements. A plurality of elements includes two or more elements. Any recitation of an element is understood to refer to at least one element. Unless otherwise required, any described method steps need not be necessarily performed in a particular illustrated order. The term “solid wood” refers to ordinary lumber, whether having any hollow spaces or not, but does not include engineered wood; engineered wood products (e.g. plywood) are manufactured by binding together wood strands, fibers or veneers with adhesives to form a composite material. The terms “monolithic” and “integrally formed” refer to structures cut from a single original piece of wood, and not structures created by assembly (whether by gluing, interlocking, fastening, or any other assembly / connection mechanism). The statement that two boards are secured in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com