Cooling systems for heat-treated parts and methods of use

a technology of heat-treated parts and cooling systems, which is applied in the direction of heat treatment equipment, manufacturing tools, furnaces, etc., can solve the problems of high thermal stress, extreme centrifugal force and extreme environmental stress during use of certain metallic parts, and the complex geometries of components of jet aircraft turbines and turbines for power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

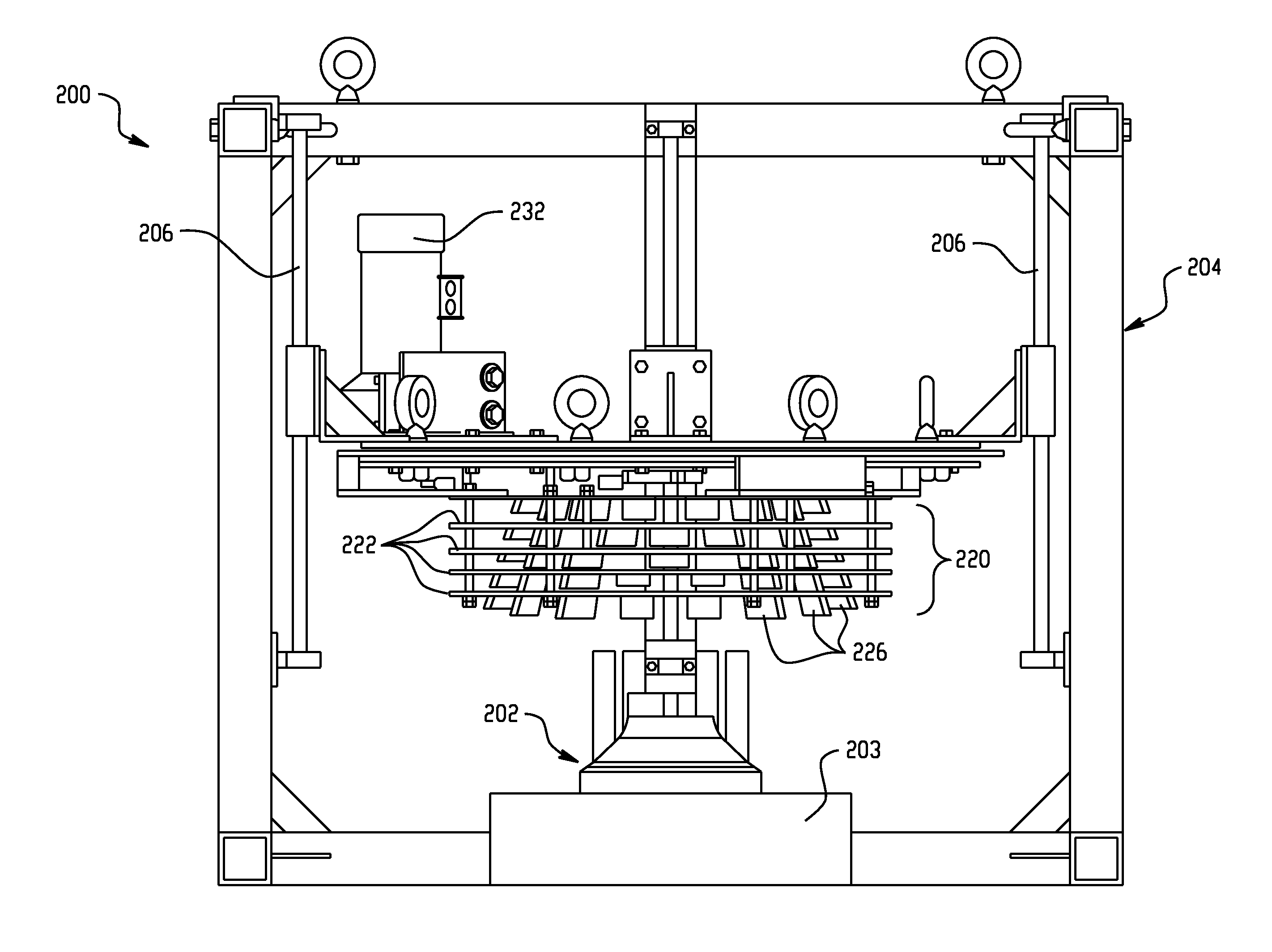

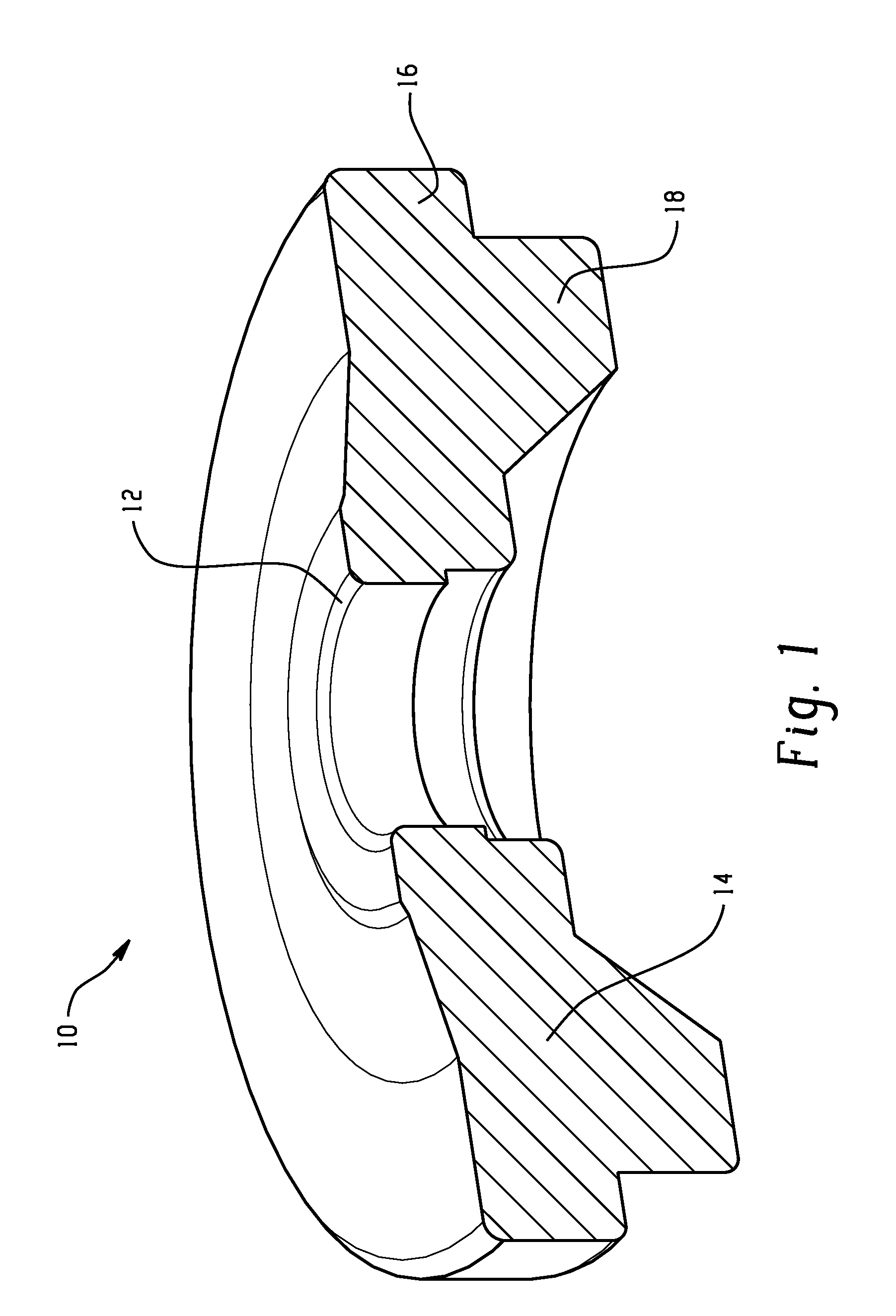

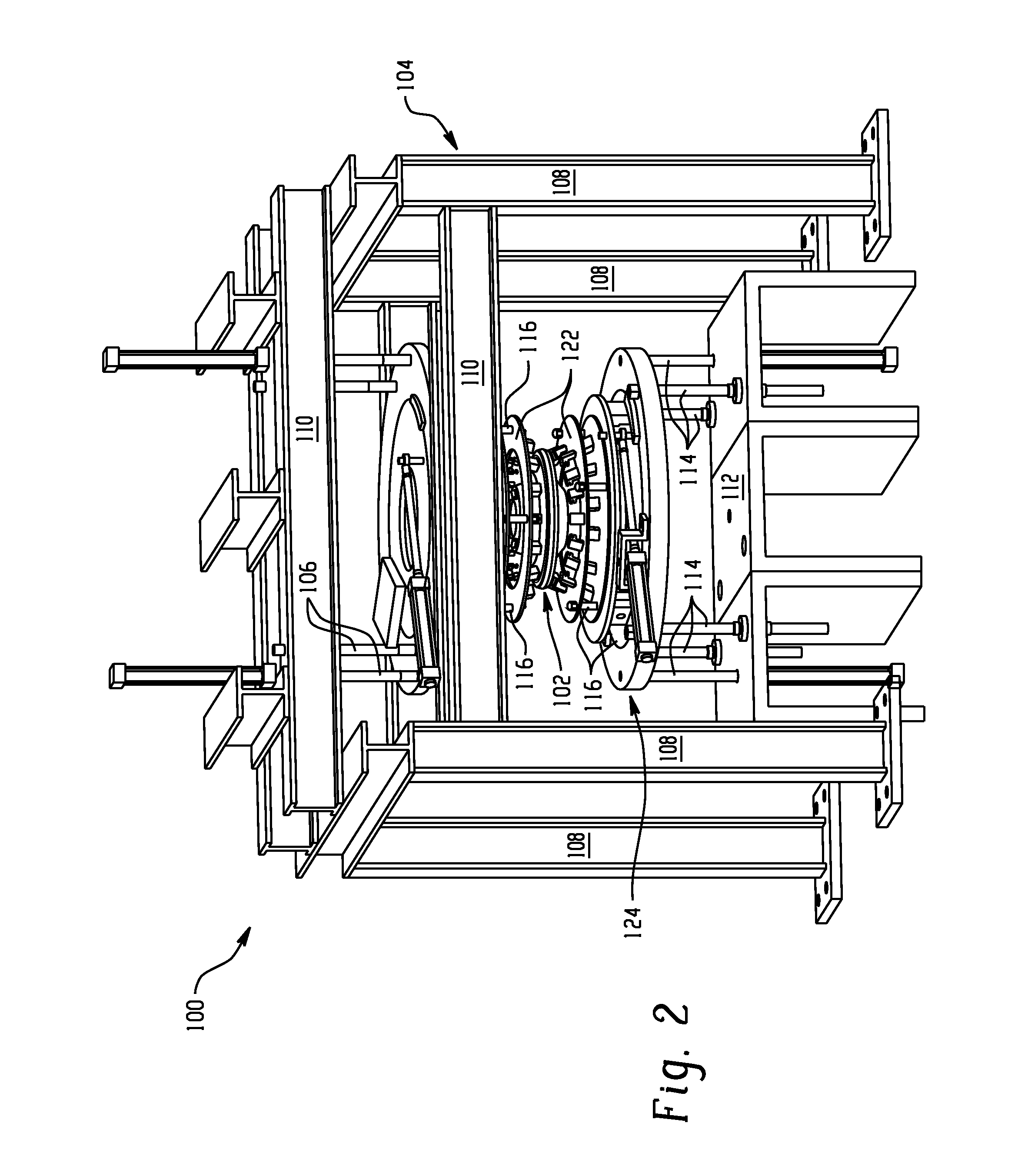

[0020]Disclosed herein are systems and methods for the rapid and highly controlled cooling of a heat-treated metallic part. The heat-treated metallic part to be cooled can be any metallic material. In some embodiments, the heat-treated part is a high temperature aerospace alloy. Typically, these materials must have adequate performance characteristics for its intended use, such as tensile strength, creep resistance, oxidation resistance, and corrosion resistance, at high temperatures. More particularly, the systems and methods are configured to maintain highly controlled cooling across the surface of the metallic part being heat-treated by tailoring the heat transfer coefficient in specific areas of the part based on the cross-sectional thickness of the part in those locations. The systems and methods disclosed herein can be particularly advantageous in the production of jet engine and gas turbine generator components, such as turbine disks, and the like.

[0021]The production of meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com