Curved display panel manufacturing method

a manufacturing method and technology applied in the field of curved display panel manufacturing methods, can solve the problems of high manufacturing cost of curved display panels, difficult manufacturing process of conventional flexible liquid crystal display panels, and inability to use curved displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Technical Problem

[0008]The present invention has been made in an effort to provide a curved display panel manufacturing method in which a phenomenon of separation of two substrates during paring and bending glass substrates facing one another can be prevented.

Technical Solution

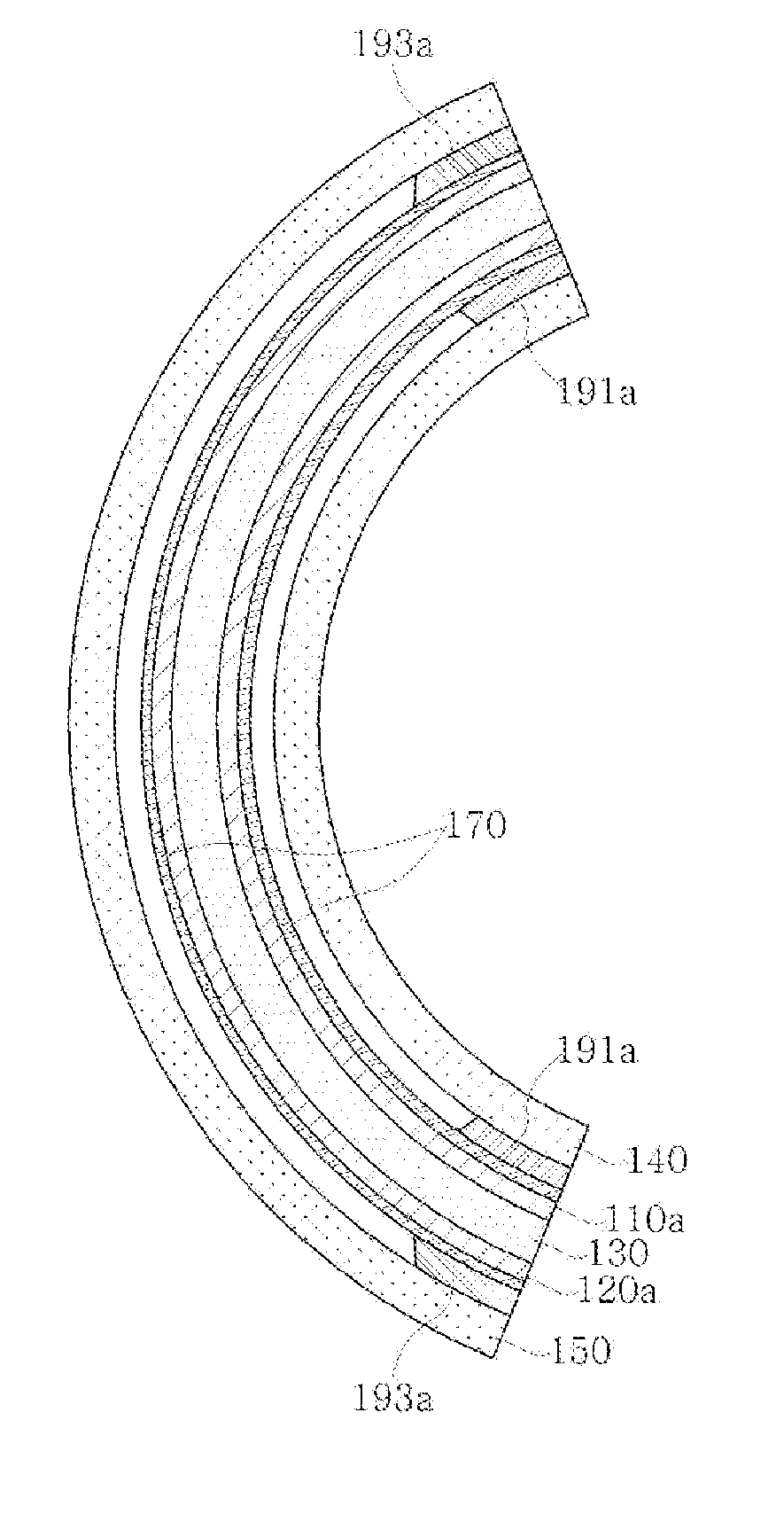

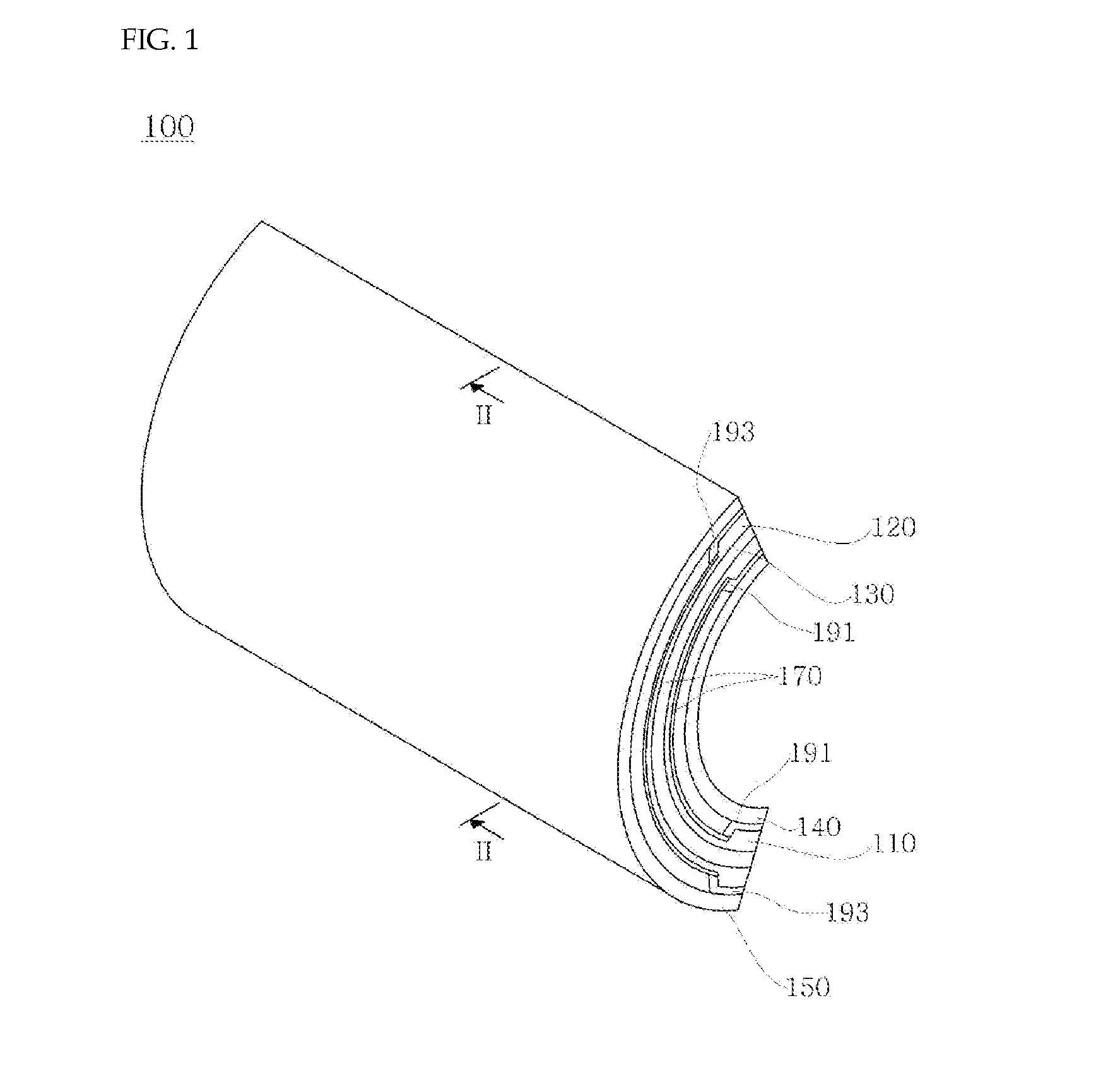

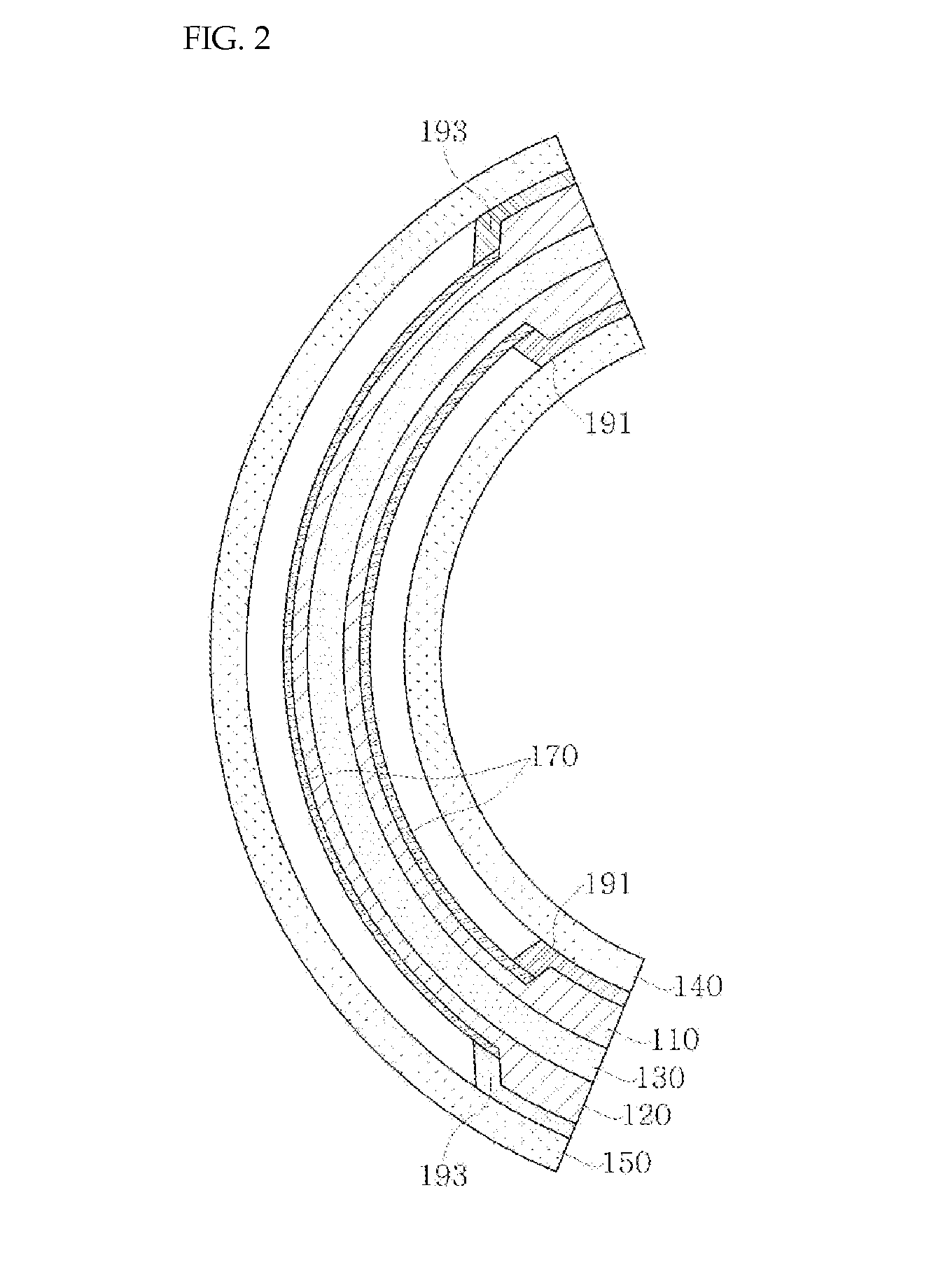

[0009]An exemplary curved display panel manufacturing method according to an embodiment of the present invention for manufacturing a curved display panel having a curved shape using a flat display panel having a first substrate and a second substrate facing one another includes: paring partially outer portions of the first substrate and the second substrate so as to reduce thicknesses thereof to predetermined thicknesses; and forming fixing layers at edge areas which are not bent in a state of being bent to the desired curved shape among the edge areas of the first substrate and the second substrate.

[0010]In the paring partially outer portions of the first substrate and the second substrate, the edge areas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com