Method and assembly for soldier pile retaining wall leveling and erosion control

a technology of retaining wall and leveling and assembly, which is applied in the direction of artificial islands, construction, marine site engineering, etc., can solve the problems of premature failure of the shore wall, erosion to occur under the shore wall, and limited life expectancy of the installation, so as to prevent erosion, delaying the erosion process, and pleasing aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

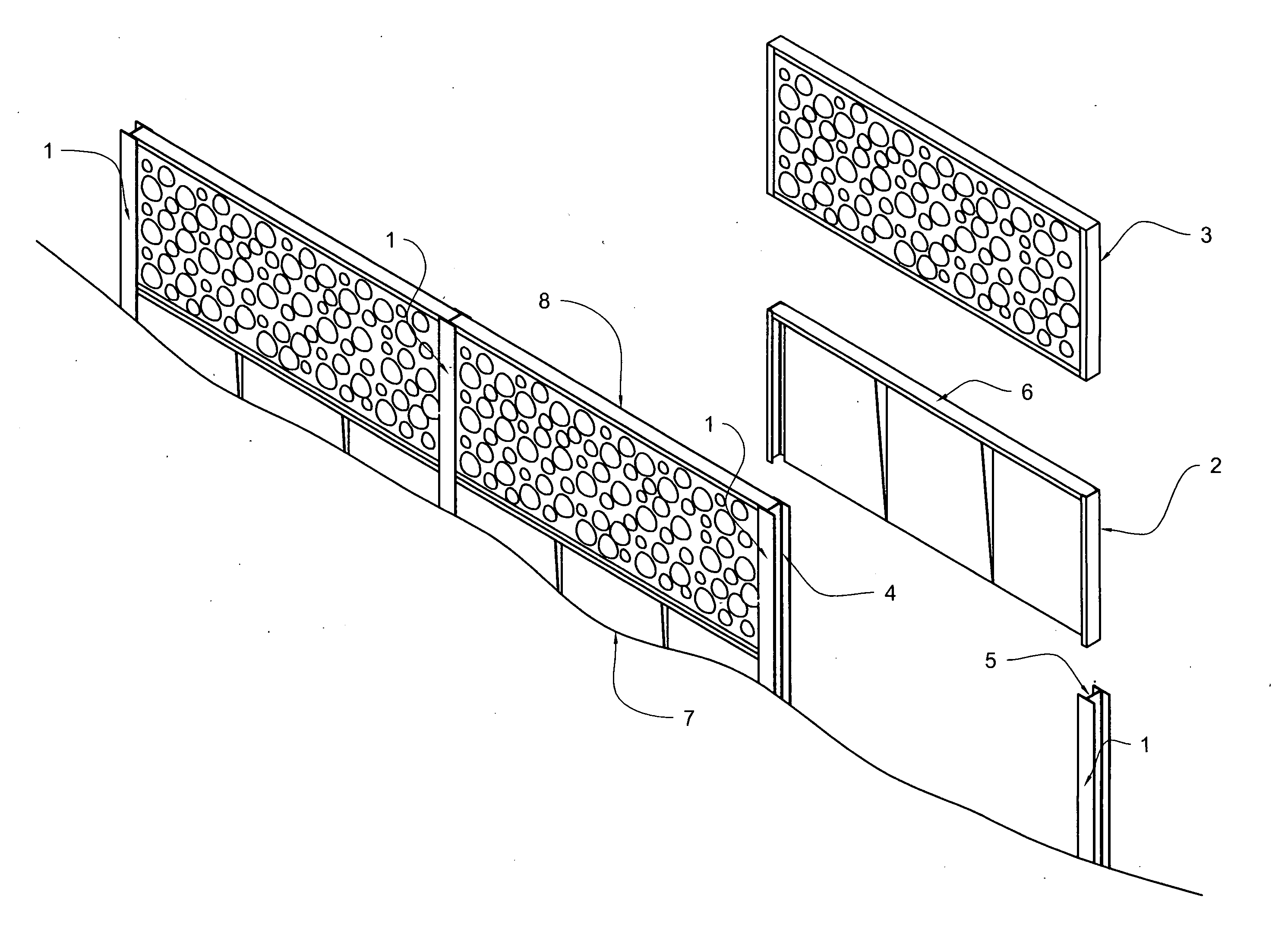

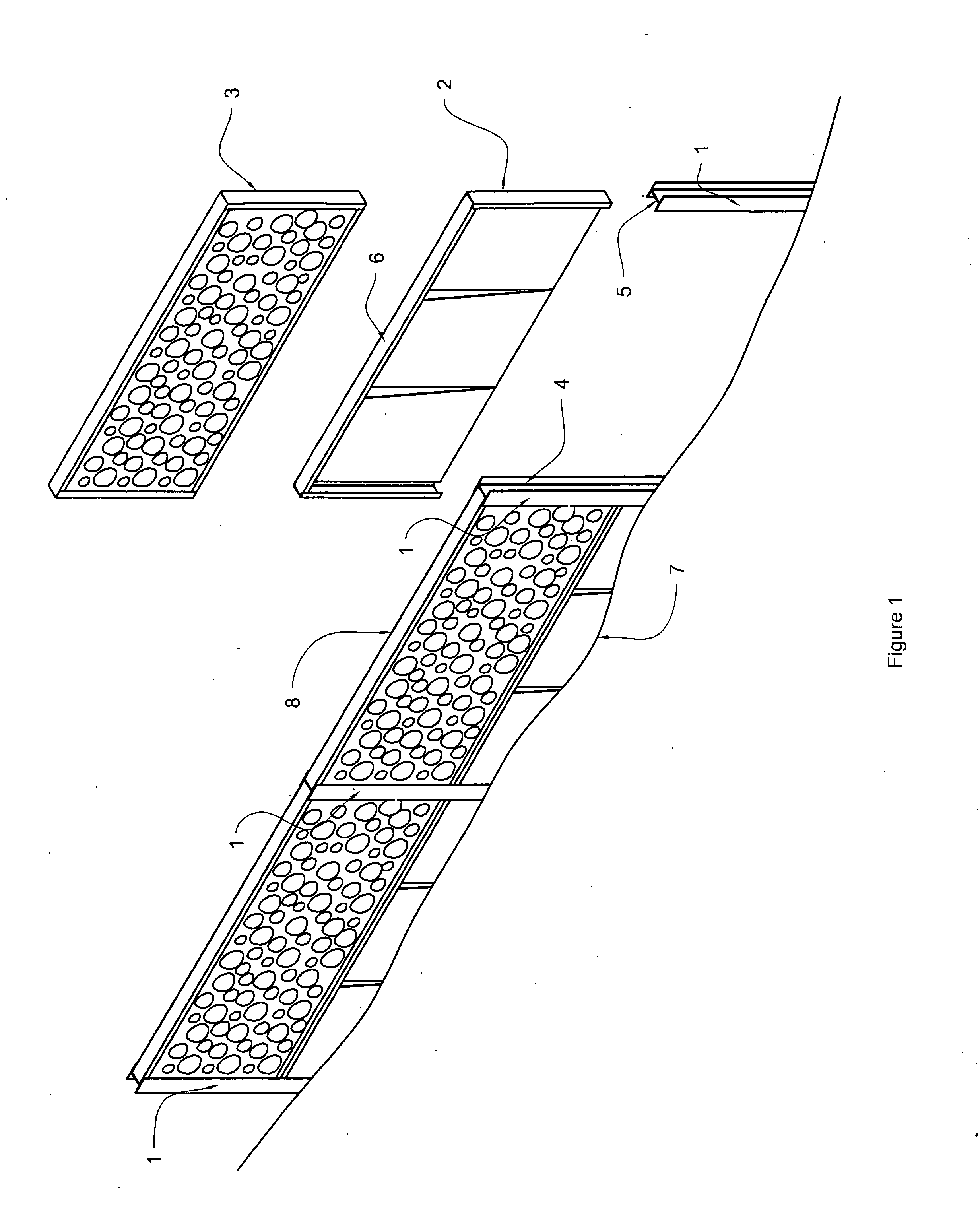

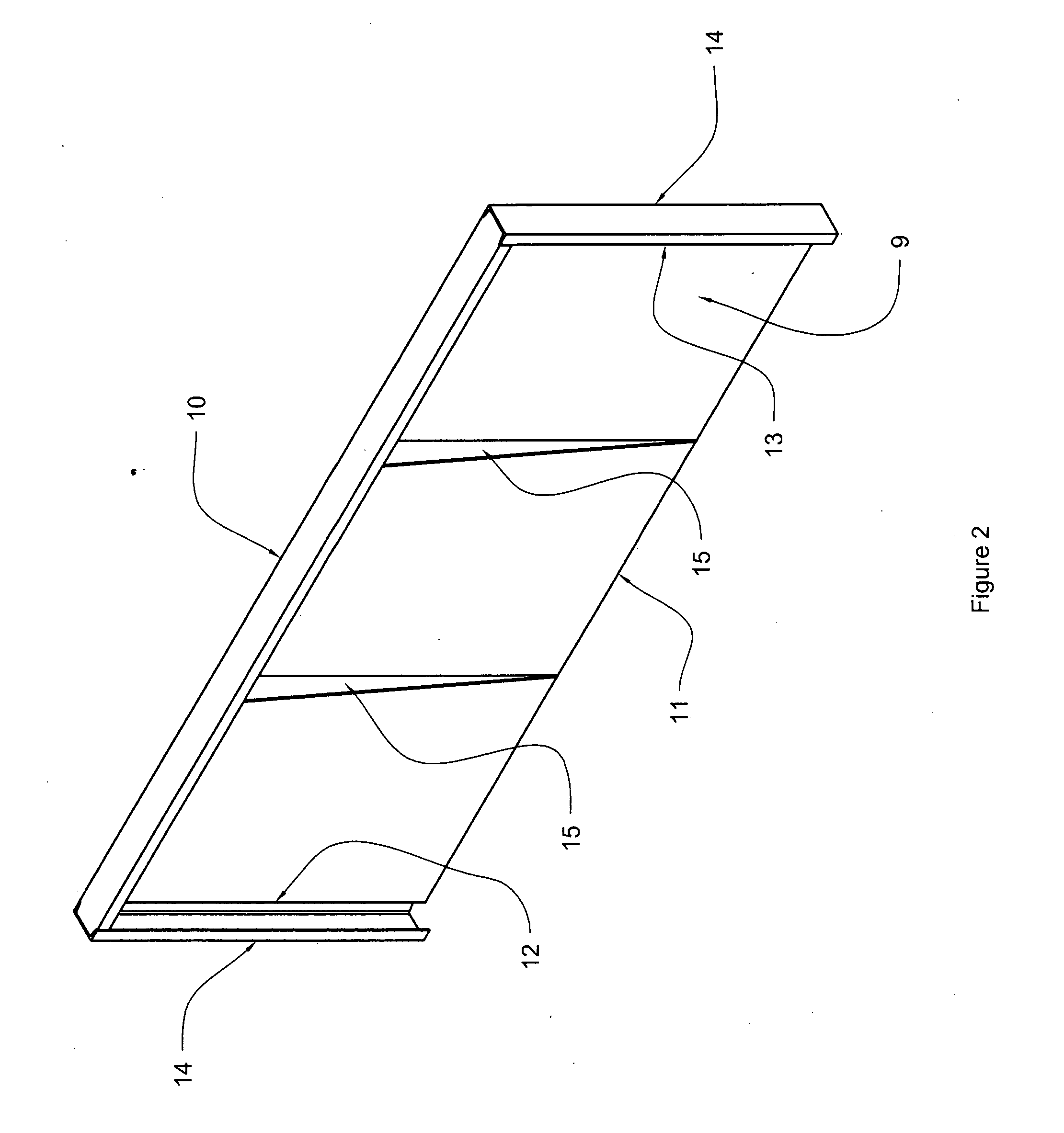

[0013]FIG. 1 illustrates one embodiment of the novel shore wall or retaining wall of the invention intended for installation along the periphery of a body of water. A plurality of vertical soldier pilings (1) are driven or pounded into the bed of the body of water along a longitudinal center line with uniform spacing equivalent to the longitudinal dimension of the shore wall base element assembly (2) and lagging panels (3). The opposing transverse slots (4-5) of the vertical soldier pilings are equivalent width to the width of the framing element (6) of the shore wall base element assembly. The side edge framing element is slotted into the receiving slot of the soldier pile which is an I-beam in the preferred embodiment. After the shore wall base element is inserted between adjacent soldier pilings, the shore wall base element is driven or pounded into the bed of the body of water (7). The same mechanism is repeated for a plurality of shore wall base elements which are driven or pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com