Centrifugal compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

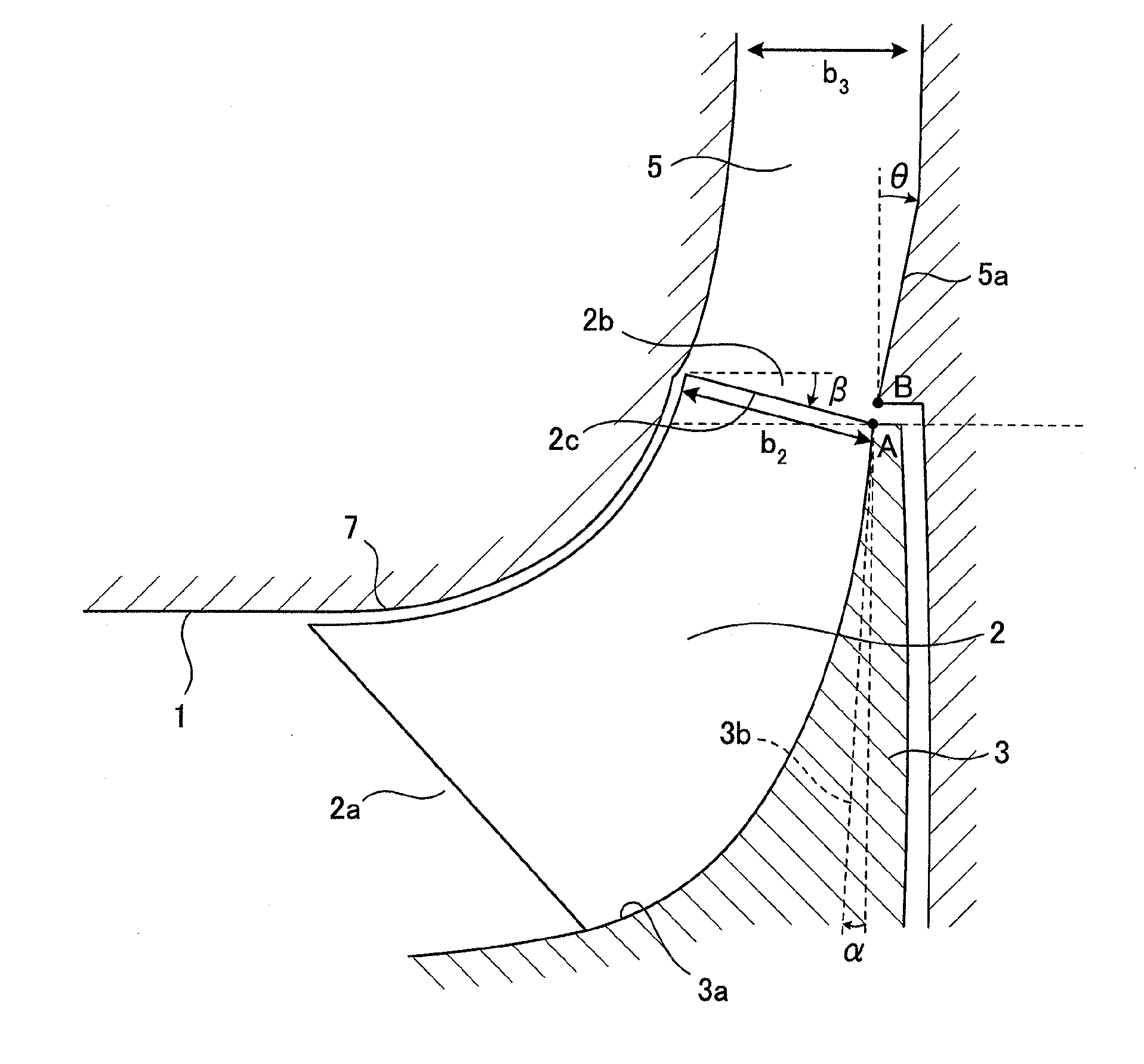

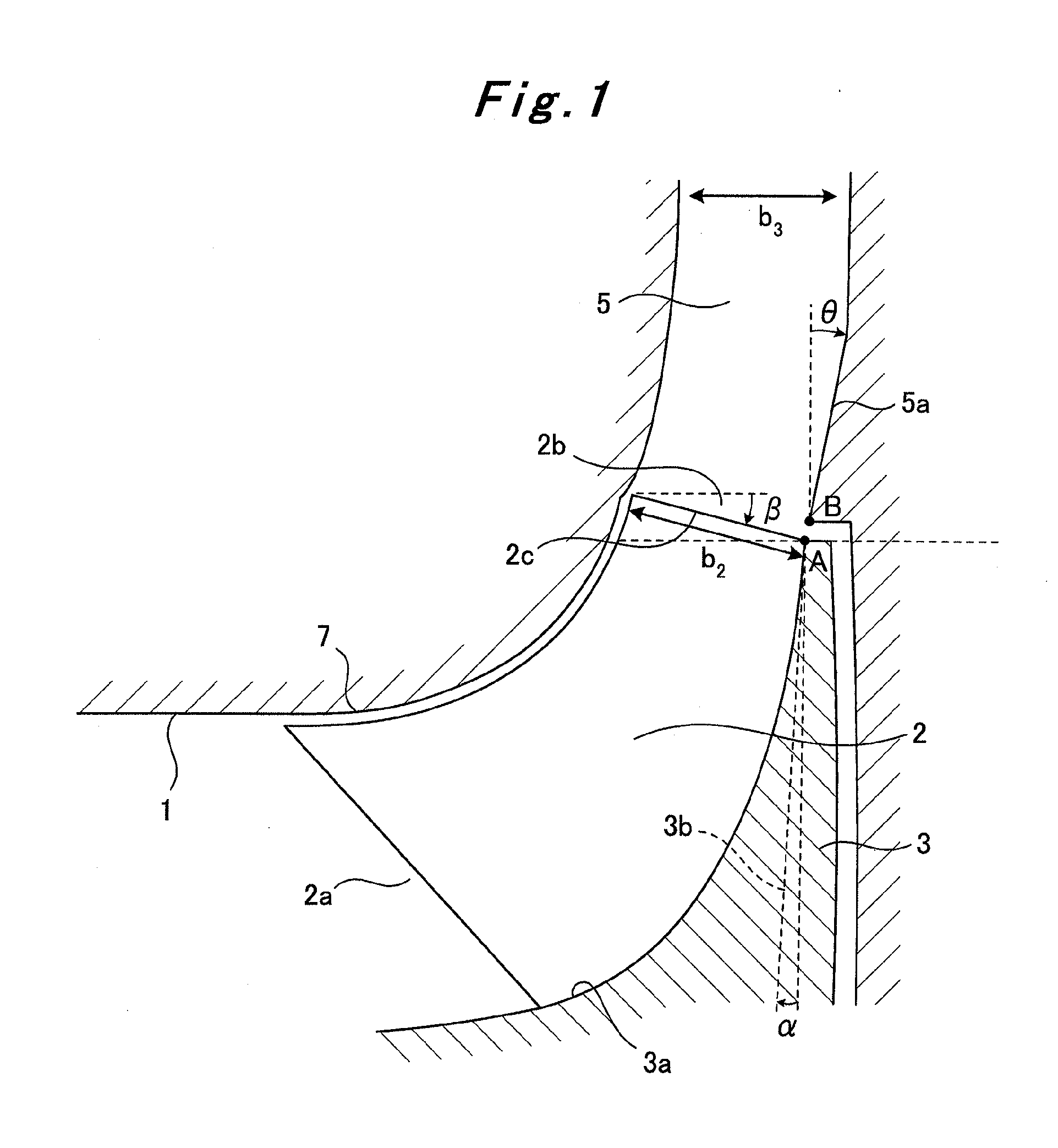

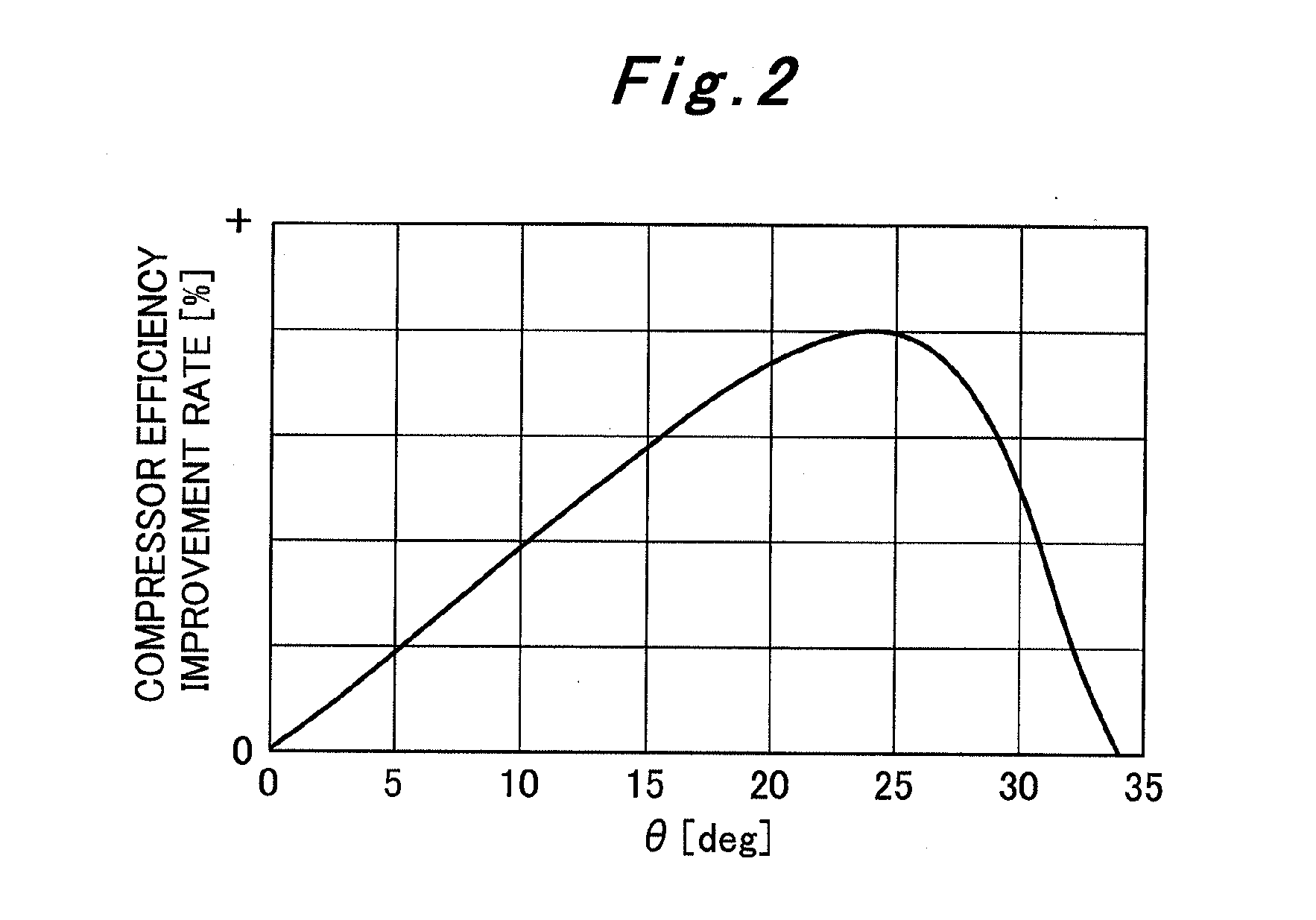

[0034]An apparatus according to Embodiment 1 of the present invention will be described by use of FIG. 1. The apparatus mainly includes a suction inlet 1, an impeller 2, a hub 3, a rotary shaft 4, a diffuser 5, and a scroll 6, as in the case of the conventional centrifugal compressor. The impeller 2 is connected to the rotary shaft 4 via the hub 3. In addition, the diffuser 5 is provided downstream of the impeller 2, has a flow passage directed in a direction away from the rotary shaft 4, and has an outlet directed in a radial direction in a meridian plane. Moreover, the scroll 6 is provided downstream of the diffuser 5, and communicates with an outlet of the diffuser 5. Note that the rotary shaft 4 and the scroll 6 are not shown in FIG. 1, but are assumed to be the same as those of the conventional technical.

[0035]Furthermore, like the conventional technique, the suction inlet 1 plays a role of guiding a gas to the impeller 2. The centrifugal compressor is configured such that the ...

embodiment 2

[0044]An apparatus according to Embodiment 2 of the present invention is one obtained by improving the apparatus according to Embodiment 1. FIG. 4 shows differences between the apparatus according to Embodiment 1 and the present apparatus. In the apparatus according to Embodiment 1, since the diffuser inlet hub-side line 5a is a straight line, directing the outlet of the diffuser 5 in the radial direction requires that the angle of the diffuser 5 has to be changed at a certain portion. As a result, as shown in FIG. 4, a stagnation region 11 where the flow of the gas stagnates is formed. Shear stress acts between the gas stagnating in the stagnation region 11 and the flowing gas, leading to a possibility of occurrence of an energy loss. The present apparatus reduces the stagnation region 11.

[0045]As in the case of the apparatus according to Embodiment 1, as shown in FIG. 3, the present apparatus mainly includes a suction inlet 1, an impeller 2, a hub 3, a rotary shaft 4, a diffuser 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com