Oil well safety valve apparatus and method

a safety valve and oil well technology, applied in the direction of earth-moving tools, wellbore/well accessories, constructions, etc., can solve the problem of still occurring blowou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

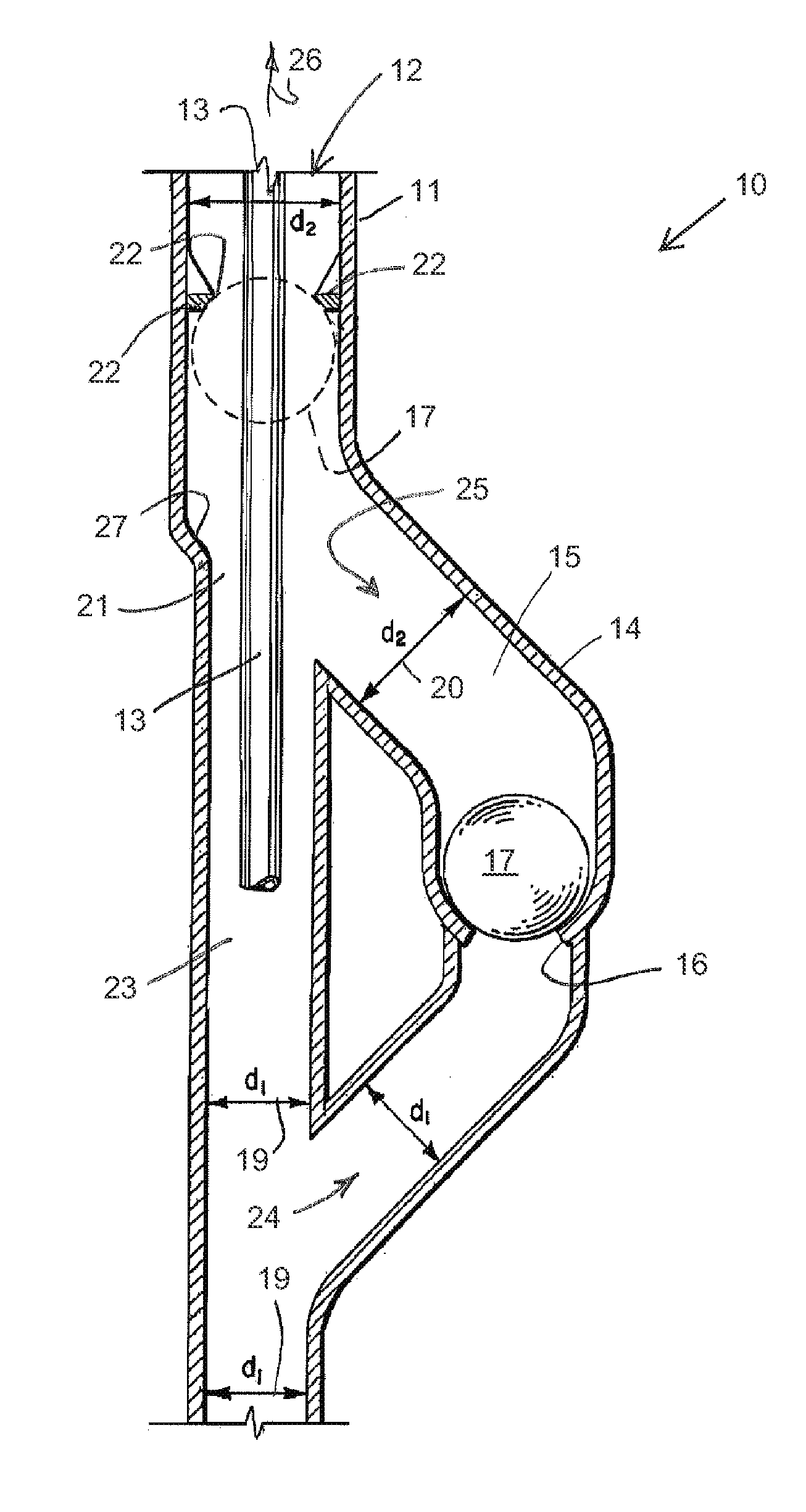

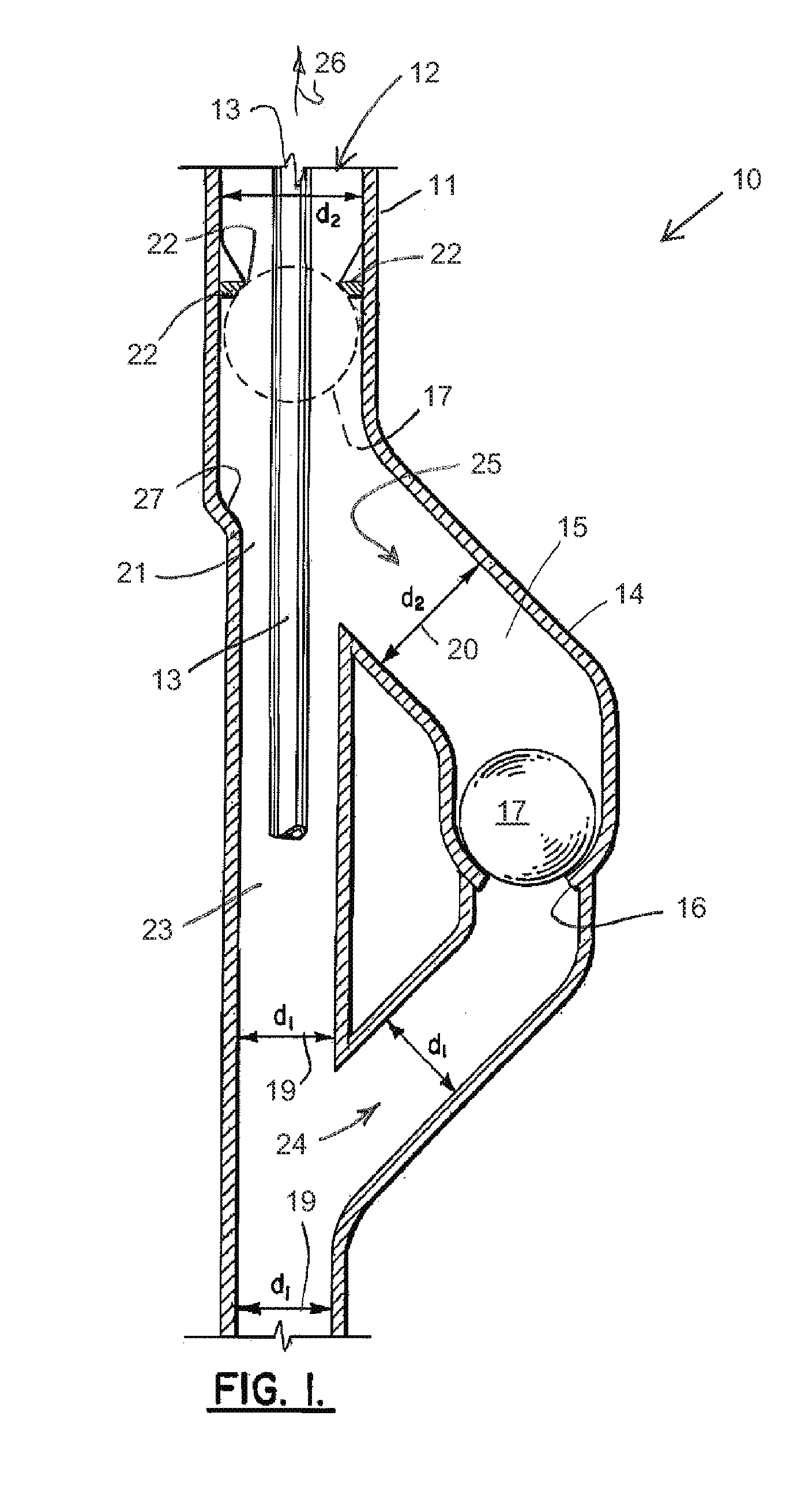

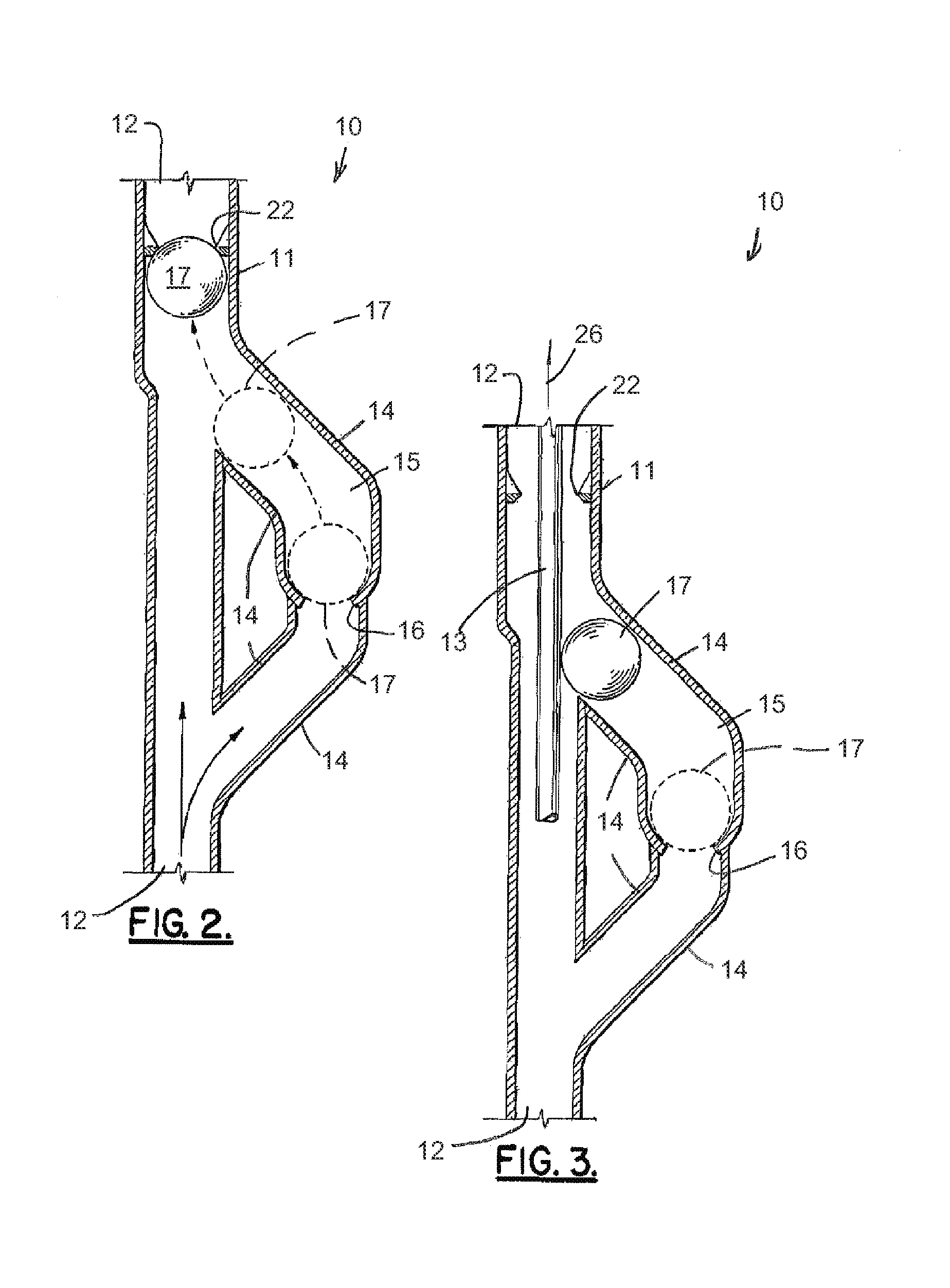

[0029]Oil well safety shut off apparatus is shown in FIGS. 1-7, designated generally by the numeral 10. Oil well safety shut off apparatus 10 can be used in a well casing 11 that surrounds a well bore 12 and blow out preventer (BOP) 18. In FIG. 7, a marine use is shown with drill ship 30, casing 11, blow out preventer 18 and seabed 31. Oil producing formation 32 is below seabed 31.

[0030]A drill string, work string or other string 13 extends downwardly into the well bore 12 and through the first bore 23 of the device 10. Circulating mud 21 can be located in first bore 23. First bore 23 has a diameter dl designated by the numeral 19. Diameter 19 of first bore 23 and the diameter of the well bore (i.e. casing 11 internal diameter) can be equal (see FIG. 7).

[0031]A branch flow line 14 has a bore 15 with a diameter (d2) designated by the numeral 20 and larger than the diameter designated by the numeral 19. The branch flow line 14 communicates with the first bore 23 at two spaced apart po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com