Shoe having carbon fiber composite spring soles and upper support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

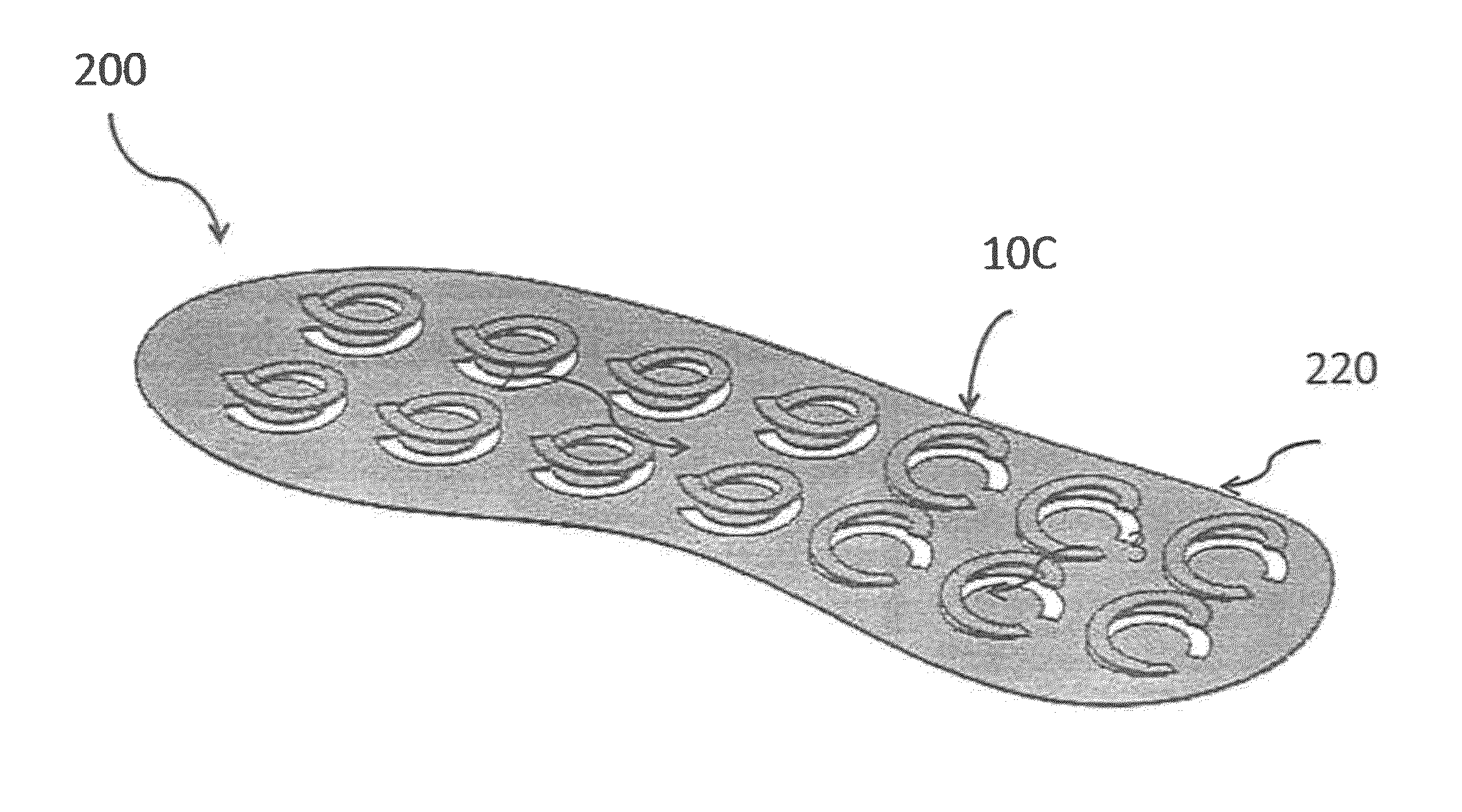

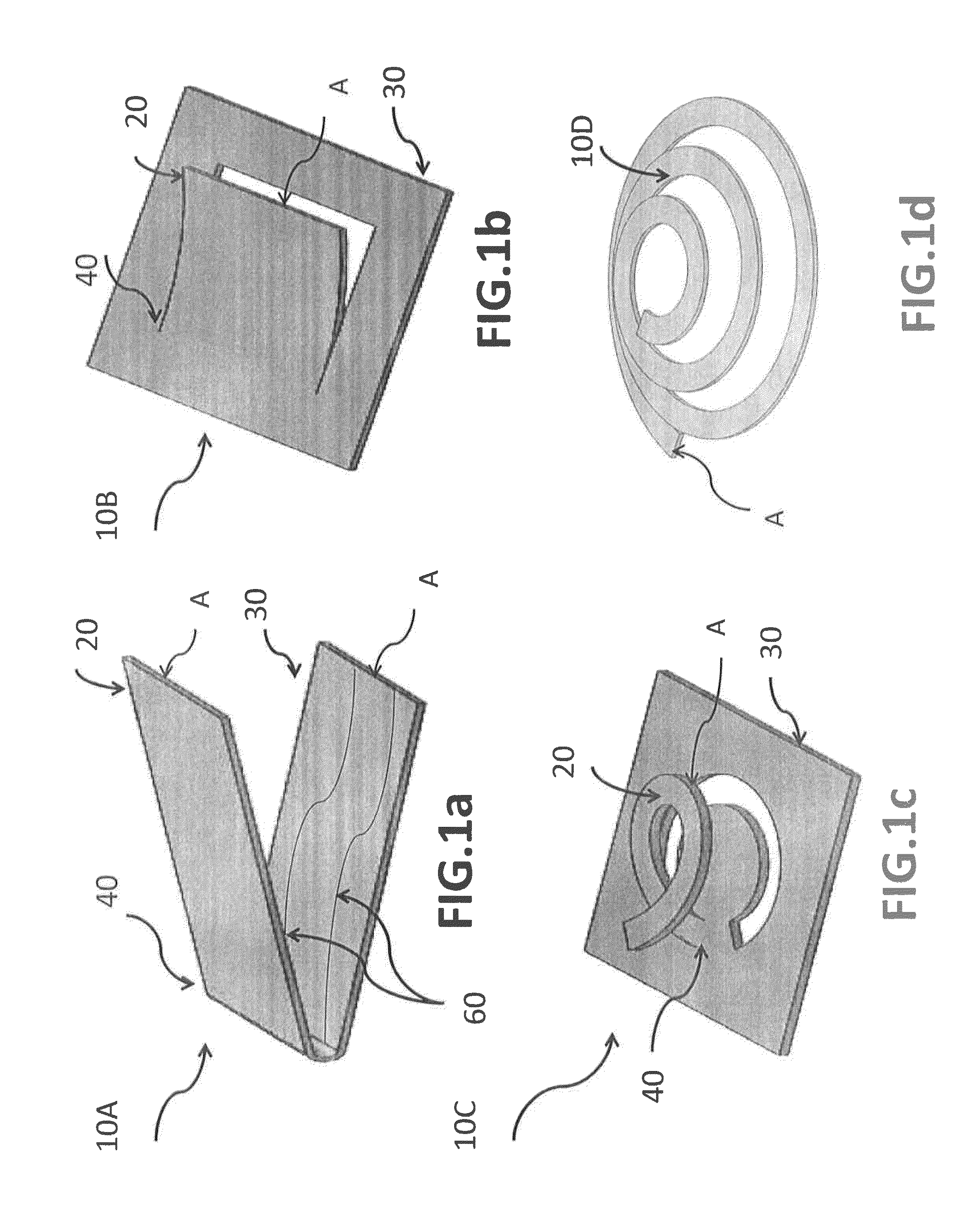

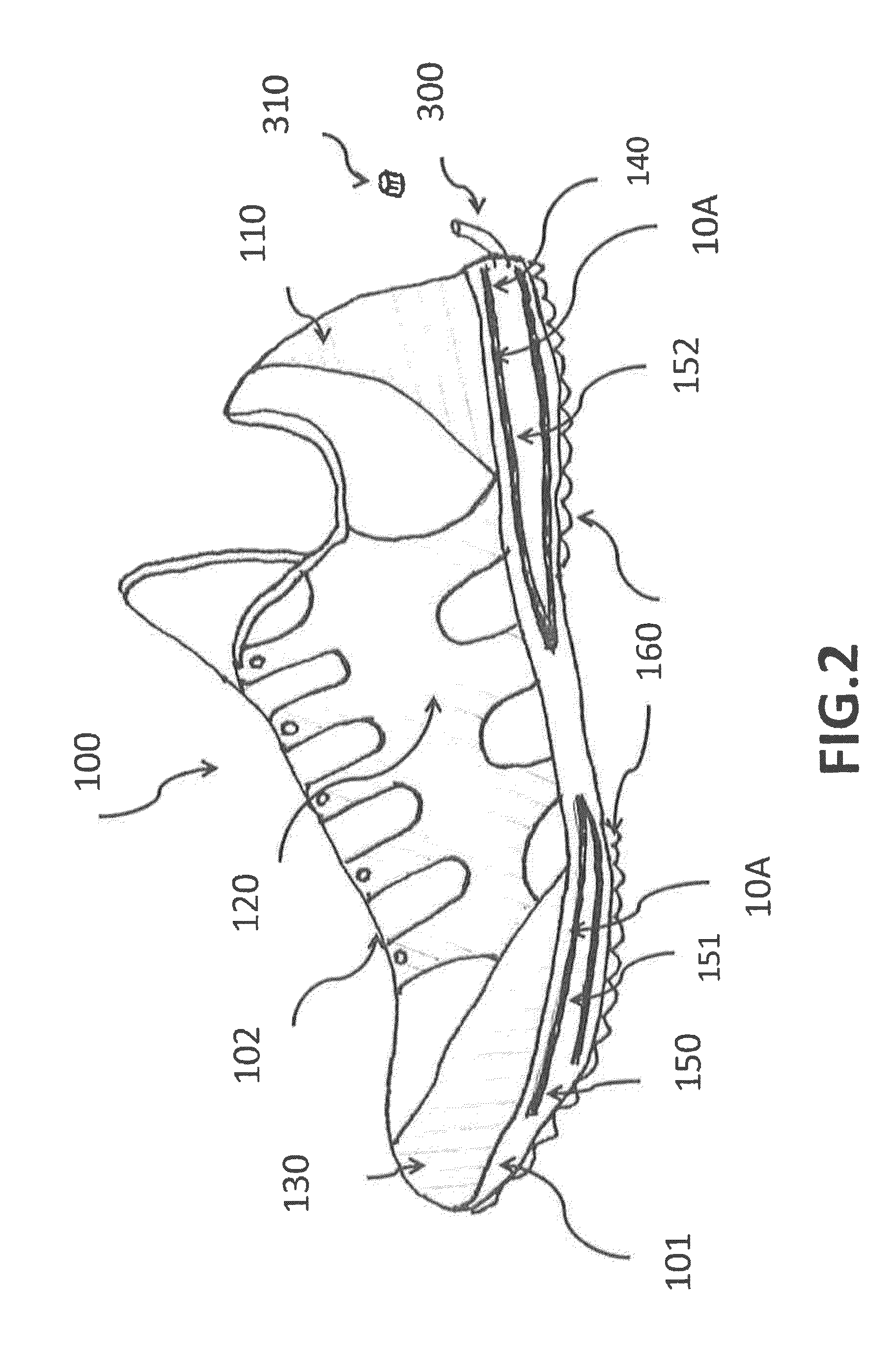

[0021]This invention provides a lightweight shoe having substantially improved shock absorption as well as energy recycling function by incorporating springs or other equivalent components made of carbon fiber composite of a variety of shapes and configurations in a variety of locations within the sole. The spring configurations of this invention are specifically tailored to carbon fiber composite properties and feature compactness that can be incorporated into a thin sole. The inventive spring design also features amenability for mass production that can be made from a single sheet or stow of carbon fiber composite with molding and curing processes. The spring cushions of this invention can be made on a single sheet that curves to fit the foot contour for comfort. The size and distribution of the springs can be further optimized to better cushion the pressure points of the foot, providing a smooth spring responsive sole for the foot, which comprises a complex bone structure. Since ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com