Fuel injection system for a turbine engine

a technology for turbine engines and fuel injection systems, which is applied in the direction of hot gas positive displacement engine plants, combustion processes, lighting and heating apparatus, etc. it can solve the problems of excessive leaning of nozzles designed to run at full load, high co production of lean flames, and limited air flow by igvs, etc., to achieve constant fuel ratio, improve efficiency, and reduce nox emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

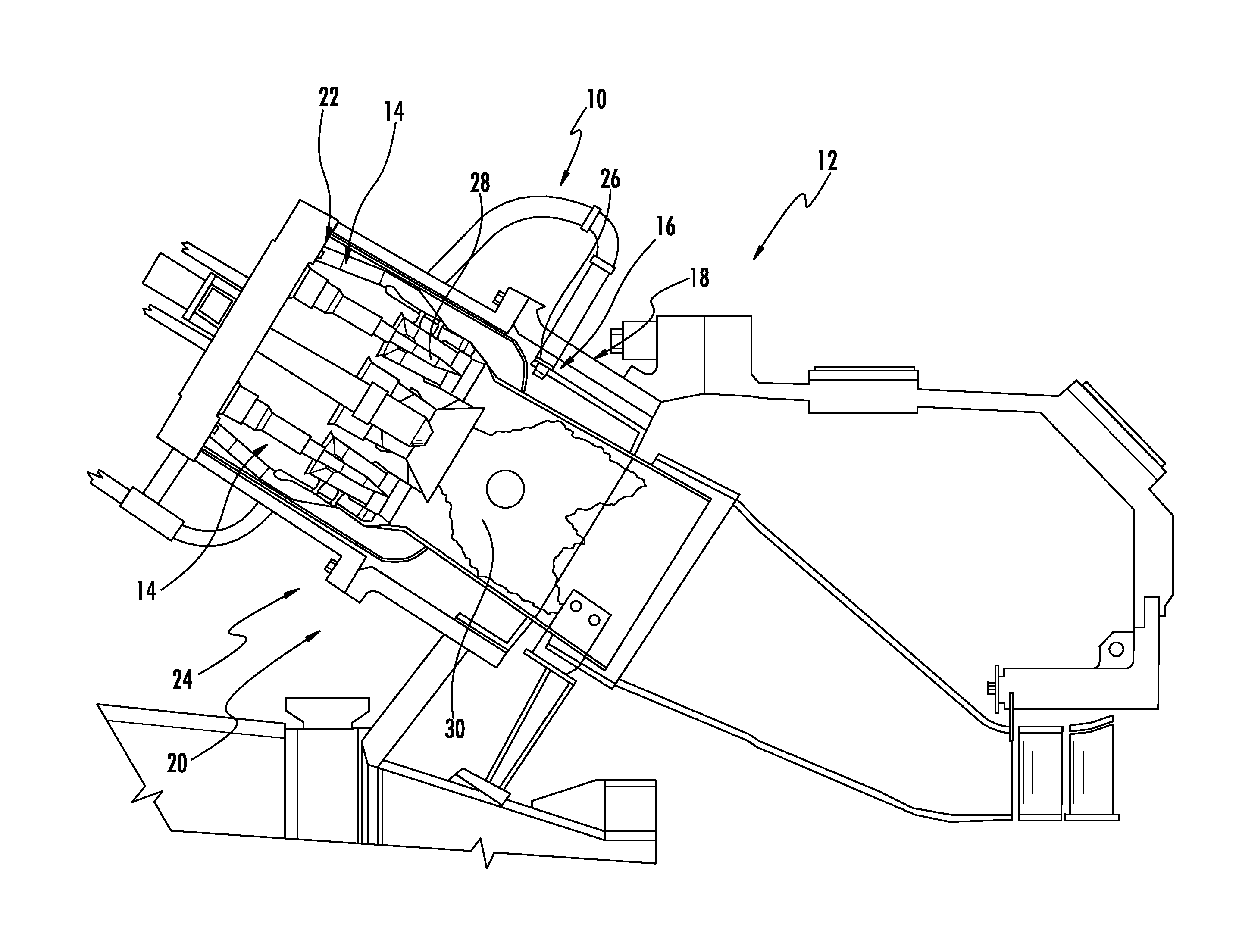

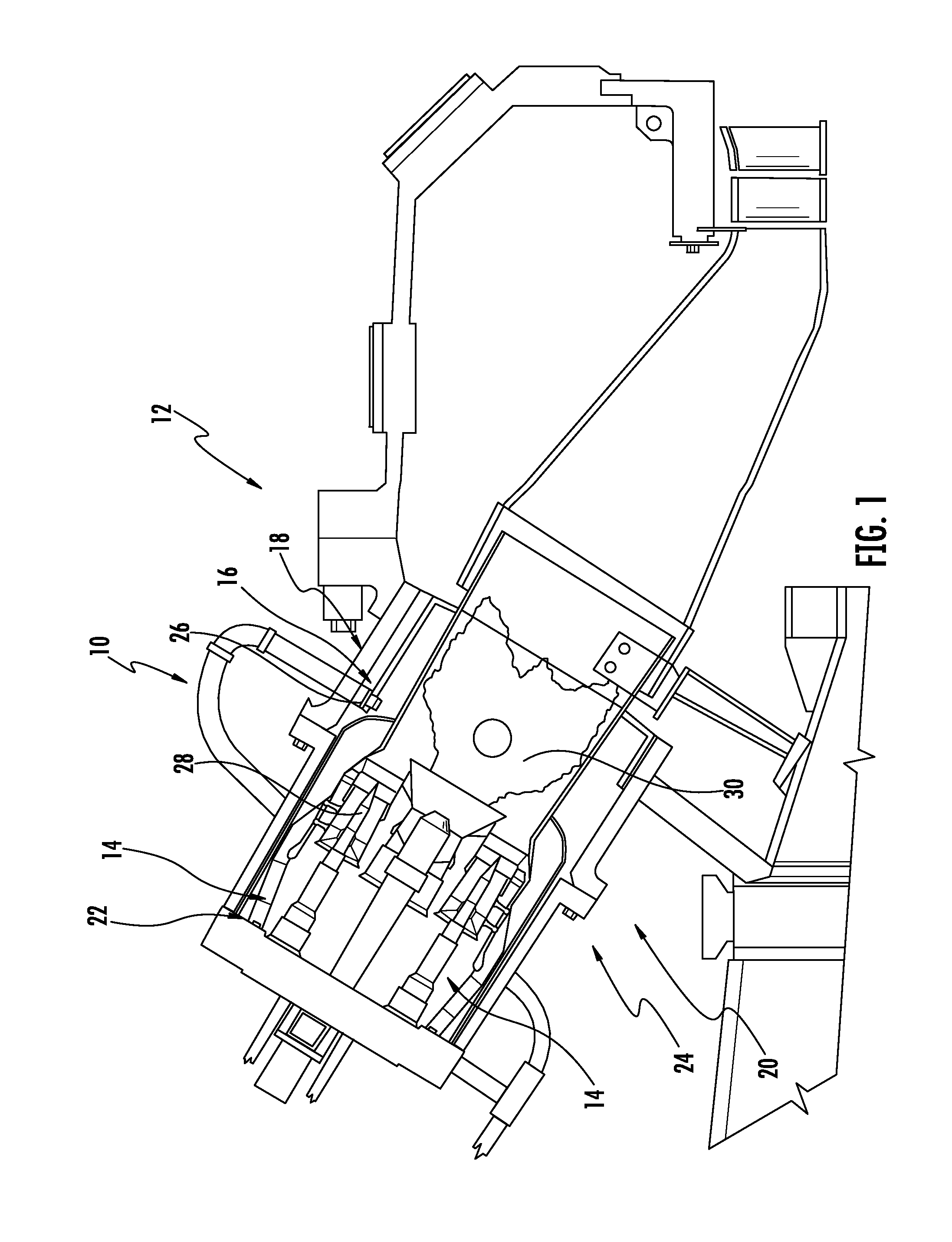

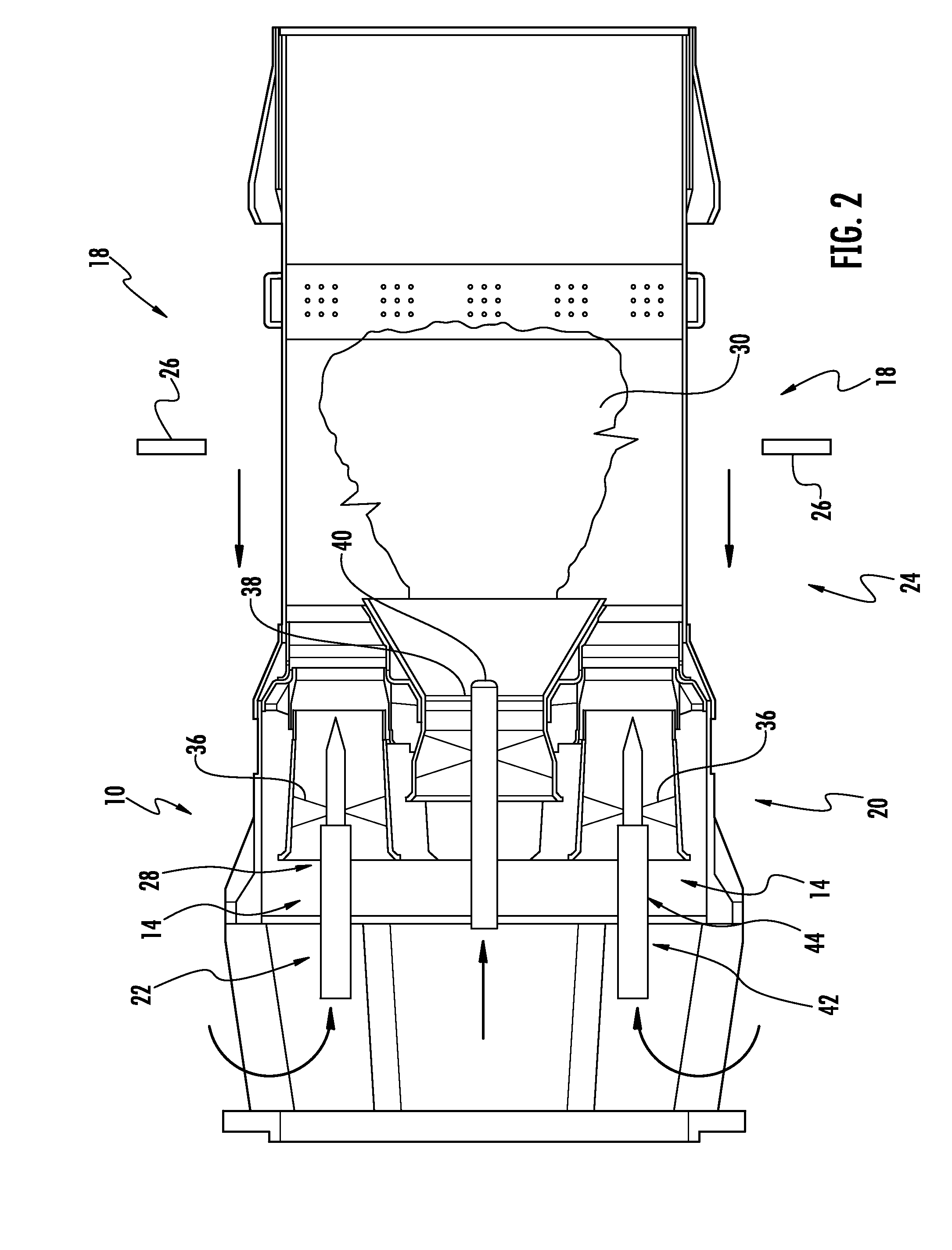

[0020]As shown in FIGS. 1-6, a fuel system 10 for a turbine engine 12 for improving the efficiency in the fuel system 10 where a major stage 14 and secondary stage 16 can be combined and held to a relatively constant fuel ratio while maintaining acceptable engine dynamics and NOx emissions is disclosed. The fuel system 10 may be formed from a first premix injector assembly stage 18 positioned upstream from a combustor basket 20, whereby the first premix injector assembly stage 18 is a secondary injector system. The fuel system 10 may be formed from a first primary injector assembly stage 22, which is a primary injector system, positioned downstream from the first premix injector assembly stage 18. The first premix injector assembly stage 18 and the first primary injector assembly stage 22 may be coupled together such that the fuel system 10 is capable of emitting fuel into a combustor 24 of the turbine engine 12 via the first premix injector assembly stage 18 and the primary injecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com