Oxidized cellulose-based material, method for obtaining same and use thereof as compress

a technology of oxidized cellulose and cellulose, applied in the field of solid materials, can solve the problems of difficult recycling, high cost, dangerous raw materials, etc., and achieve the effect of convenient transposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

OF EMBODIMENT

[0147]The invention and the resulting advantages will better appear from the non-limiting embodiments discussed hereafter.

[0148]These examples are based on fabrics made from knitted yarns of regenerated cellulose (or viscose), in crochet or jersey stitch.

I / Method of Obtaining the Solid Cellulosic Material:

[0149]1) First Step:

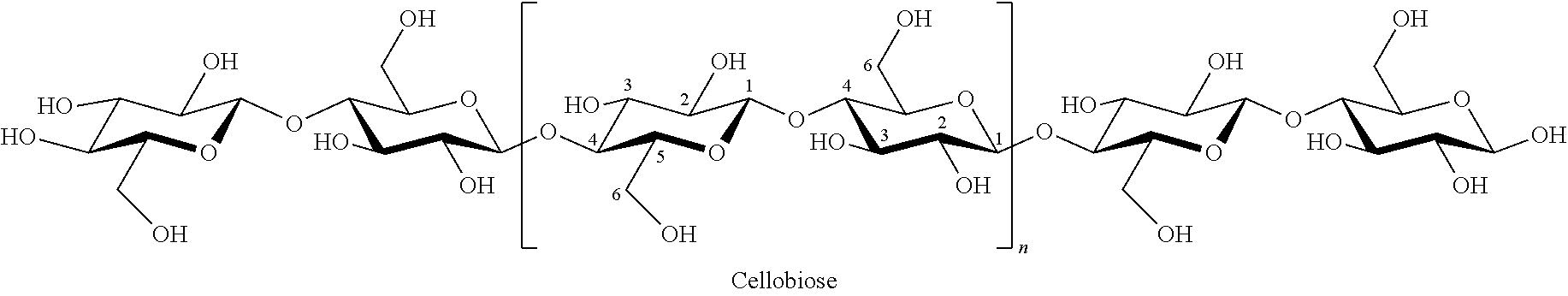

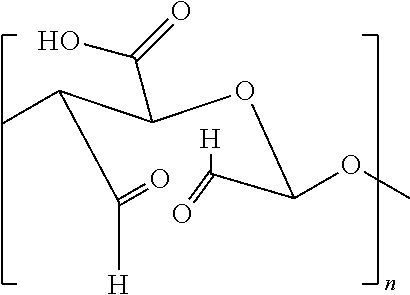

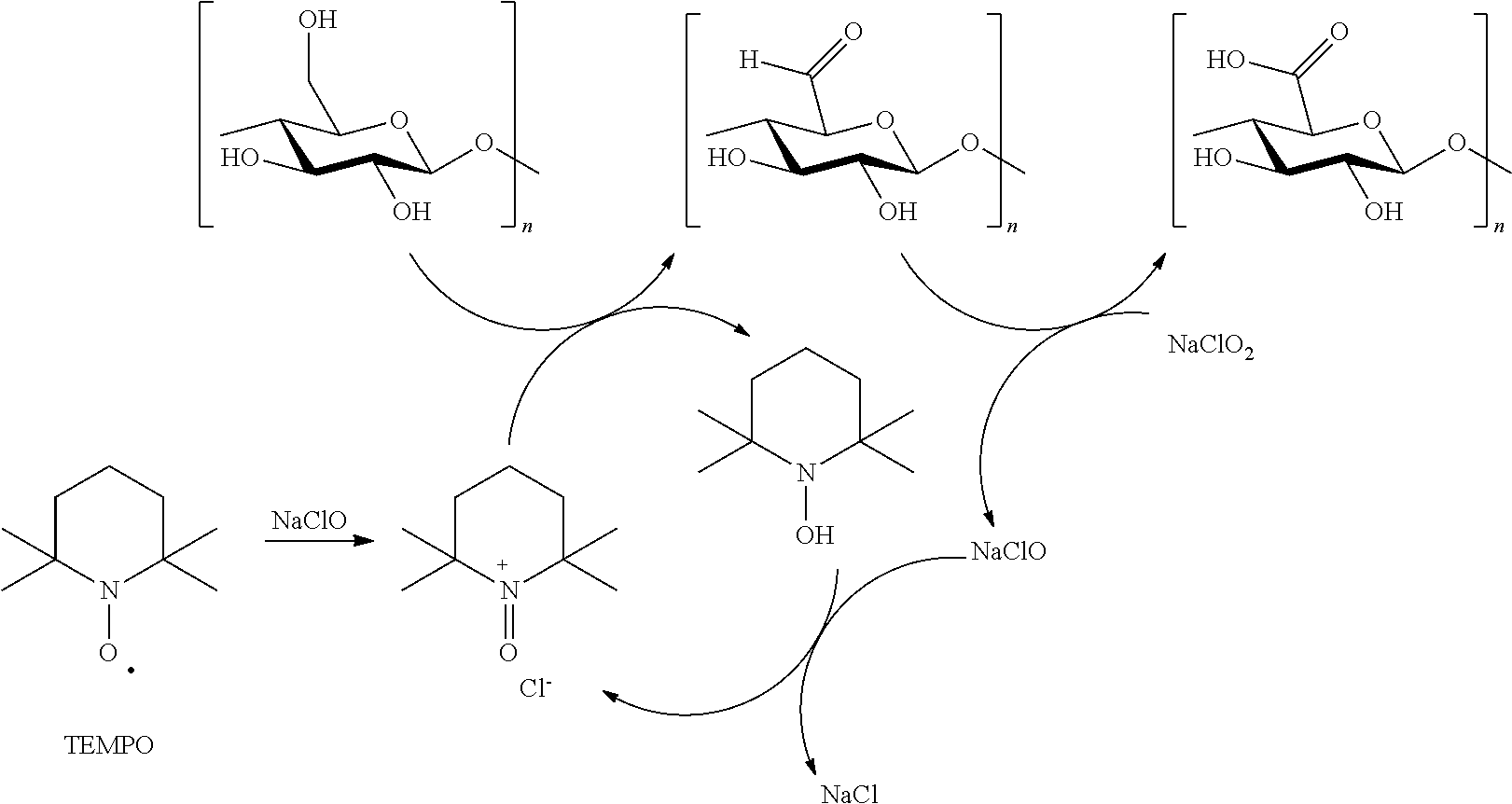

[0150]This step enables to partially oxidize the cellulose via the conversion of primary alcohol functions attached to the C6 carbon of the cellobiose units into carboxylic acid functions.

[0151]The general conditions of this step are described in Table 1 hereafter:

TEMPO (mole per gram offrom 0.0003 to 0.0006, for examplecellulose)0.0006NaClO (mole per gram offrom 0.0006 to 0.0049, for examplecellulose)0.0012NaClO2 (mole per gram offrom 0.006 to 0.025, for example 0.012cellulose)pH of the reaction mediumfrom 5 to 7, for example 5.8Temperature (° C.)60Duration of the reaction (h)from 1 to 6, typically from 4 to 5

[0152]Under a ventilator, 200 ml of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com