Energy Efficient Shingles

a technology of energy-efficient shingles and shingles, which is applied in the direction of sustainable buildings, transportation and packaging, chemistry apparatus and processes, etc., can solve the problems of worse problems and none of the available techniques have produced energy-efficient roofing that is affordable, and achieve the effect of reducing heat islands in urban areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

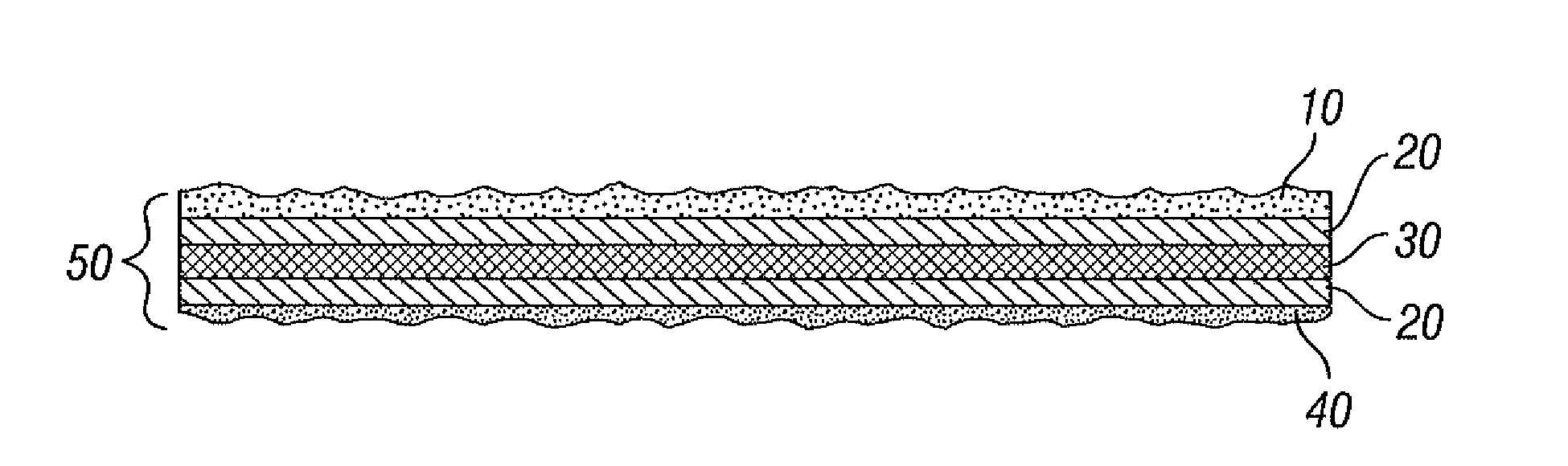

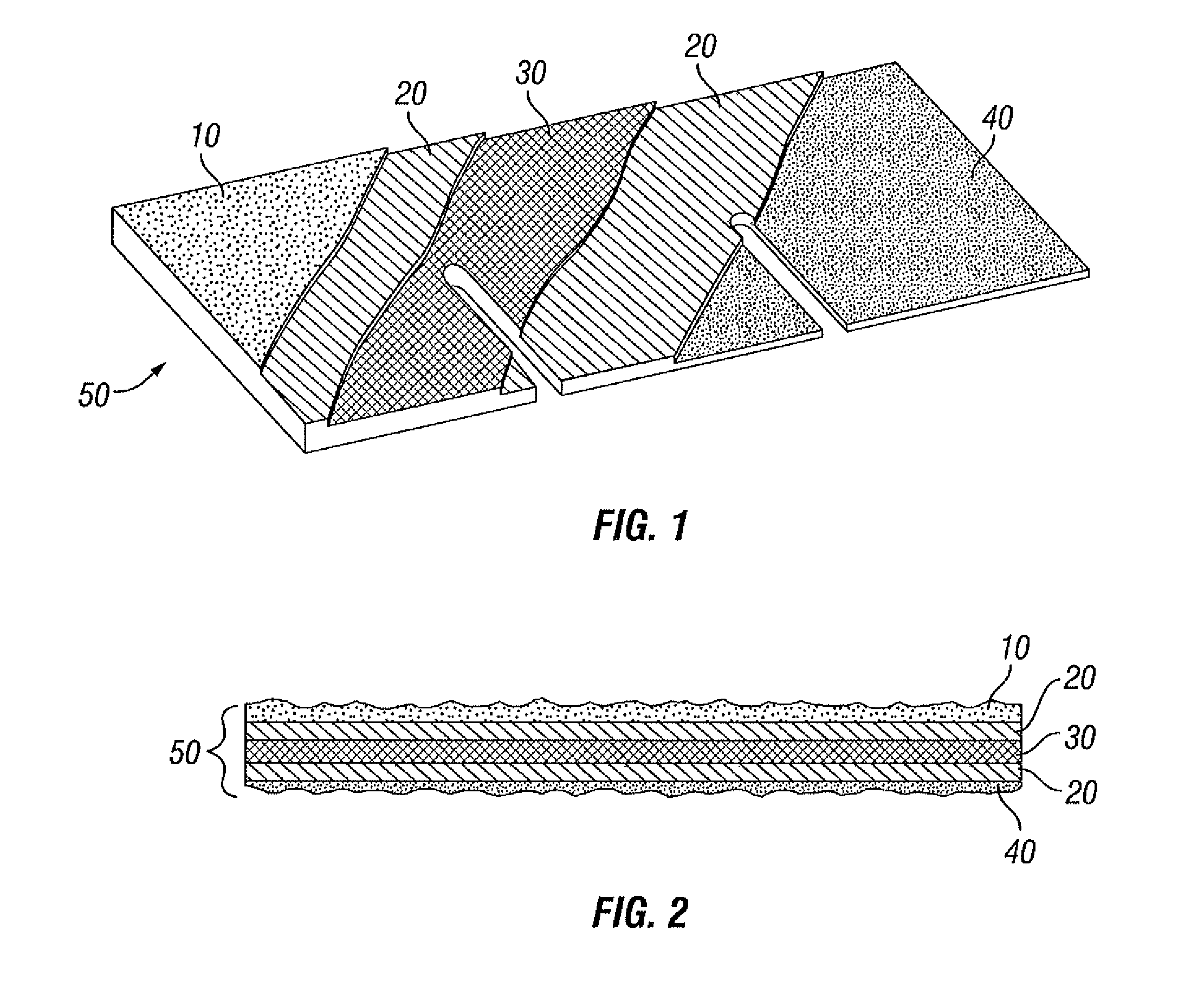

Image

Examples

example 1

Prototype Shingle

[0037]The filler mixture was prepared with air blown asphalt with a viscosity of 33,500 cP (centipoise) (the viscosity was measured at 135° C.). The air blown asphalt was heated to 204° C. to lower the viscosity and allow for better mixing with the recycled glass. The recycled glass (with size ranging from 53 μn to 75 μm) was heated to a 100° C. The recycled glass is added to the binder according to the measurements shown in Table 1 and mixed thoroughly. The viscosity of the mixture was measured at 204° C. and 150° C. and was found to be 20,000 cP and 33,940 cP. The mixture was placed back in the oven and heated to 230° C. For a sample of 3″×3″, 14.7 g air blown asphalt and 27.3 g recycled glass (35:65 ratio) was used for layer two.

TABLE 1ANATOMY OF SHINGLE SAMPLEBY WEIGHT PERCENT (Grams)BY WEIGHTFiberglass Matting (3″× 3″)2.0 4%Filler Mixture36.0 68%Asphalt (35%)12.6 24%Glass Cullet (65%)23.4 44%Top Surface Glass Cullet13.0 24%Backdust Glass Cullet2.20 4%Total Shin...

example 2

Solar Reflectance Index (SRI)

[0044]SRI incorporates both solar reflectance and emittance into a single value and is a measure of the constructed surface's ability to stay cool in the sun by reflecting solar radiation and emitting thermal radiation. It is defined such that a standard black surface (initial solar reflectance 0.05, initial thermal emittance 0.90) has an initial SRI of 0, and a standard white surface (initial solar reflectance 0.80, initial thermal emittance 0.90) has an initial SRI of 100. Materials with the highest SRI values are the coolest choices for roofing.

[0045]Table 2 displays the SRI of conventional asphalt shingles.

TABLE 2SOLAR REFLECTANCE INDEX OF CONVENTIONALASPHALT SHINGLESTYPE OF THE TYPE OF THE ASPHALT SHINGLESRIASPHALT SHINGLESRIWhite21Black1Gray4Weathered Wood4Green18Dark Brown4Antique Silver19Beachwood Sand19

[0046]Table 3 displays the SRI of the novel asphalt shingle.

TABLE 3SOLAR REFLECTANCE INDEX OF NOVEL ASPHALT SHINGLESMaterial CompositionIDTop Sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com