Hydraulic hammer device for excavators

a hydraulic hammer and excavating technology, applied in mechanical machines/dredgers, portable drilling machines, manufacturing tools, etc., can solve the problems of significant yield loss with the conventional solution, low yield improvement in practice, and blowing to the ground rod and the ground, so as to improve the overall yield of the machine, the effect of improving the overall yield and reducing the pressure fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

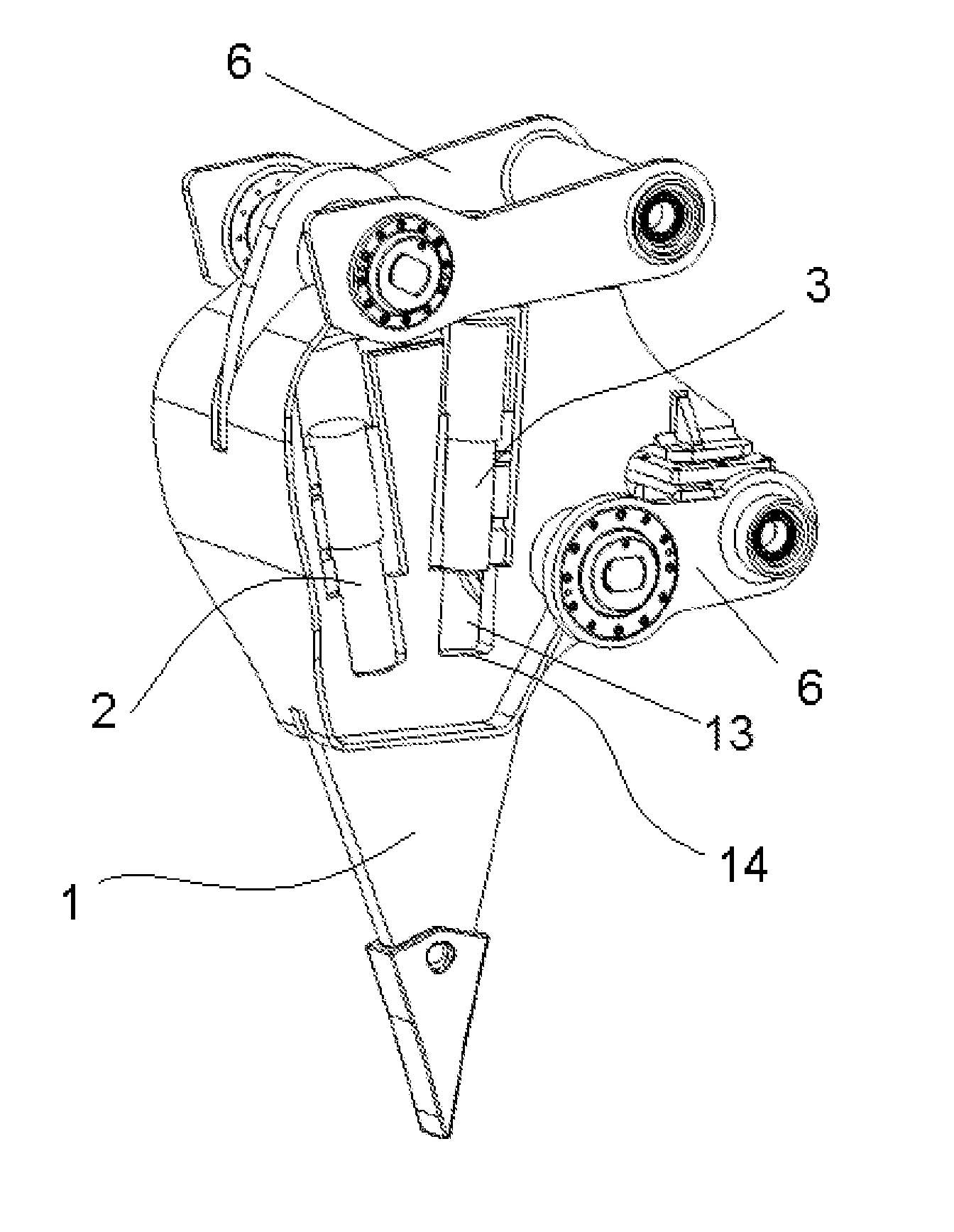

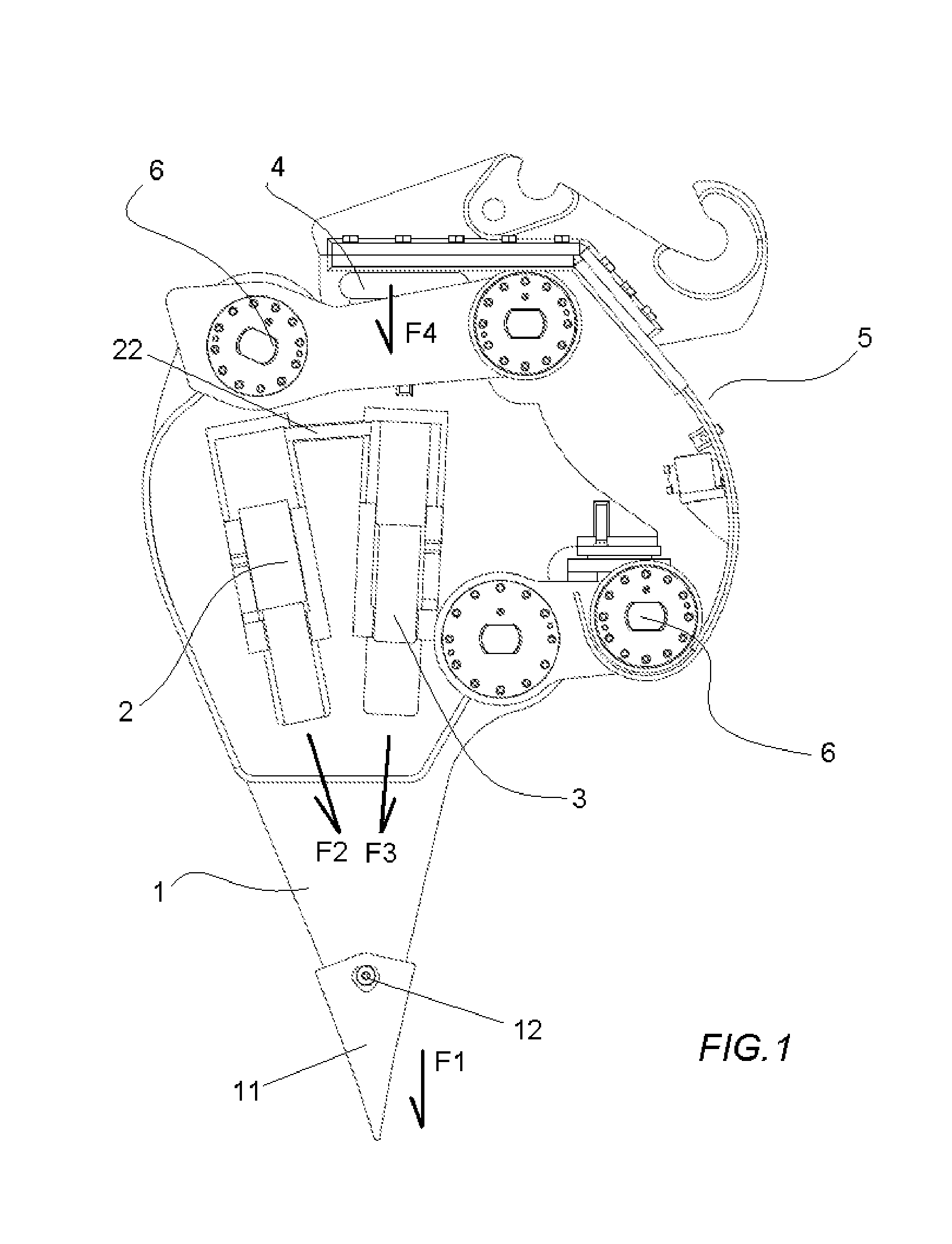

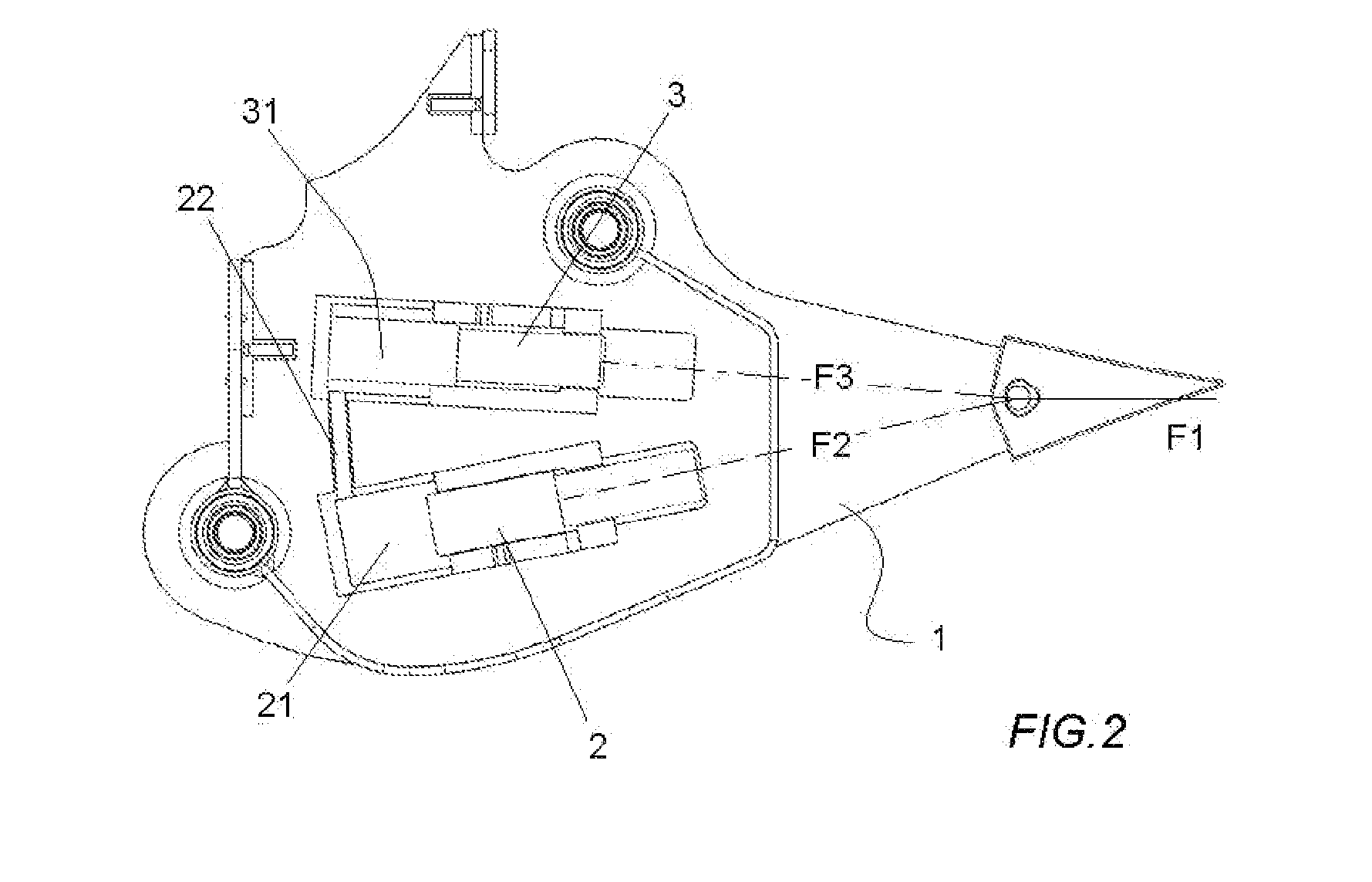

[0025]As can be seen in the attached drawings, the hydraulic hammer device for excavators object of the present invention is used for delivering blows to and digging up extremely hard grounds, such as rock (granite) and the like. The device essentially comprises a ripper (1) itself, at the lower end of which there is arranged a tooth (11) connected to the body of the ripper (1) by means of a bolt (12) or the like, such that said tooth (11) can be replaced if it wears out.

[0026]Inside the body of the ripper (1), in a space (13) provided for such purpose, there are housed two cylinders (2,3) integrally connected to the body of the ripper (1) and arranged with respect to one another such that the force vector (F2,F3) of both cylinders (2,3) is oriented towards one and the same point coinciding with the attack vector (F1) which attacks the bottom of the ripper and which in this embodiment coincides with the connection point (12) of the tooth (11) with the ripper (1).

[0027]In this practi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com