Heater pattern including heaters powered by wind-electricity for in situ thermal processing of a subsurface hydrocarbon-containing formation

a hydrocarbon-containing formation and heater pattern technology, which is applied in the direction of fluid removal, insulation, borehole/well accessories, etc., can solve the problems of high cost of mining and upgrading tar sand, high cost of upgrading, and poor quality of oil produced from such retorting, etc., and achieves the effect of increasing the rate of hydrocarbon fluid production and high spatial density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

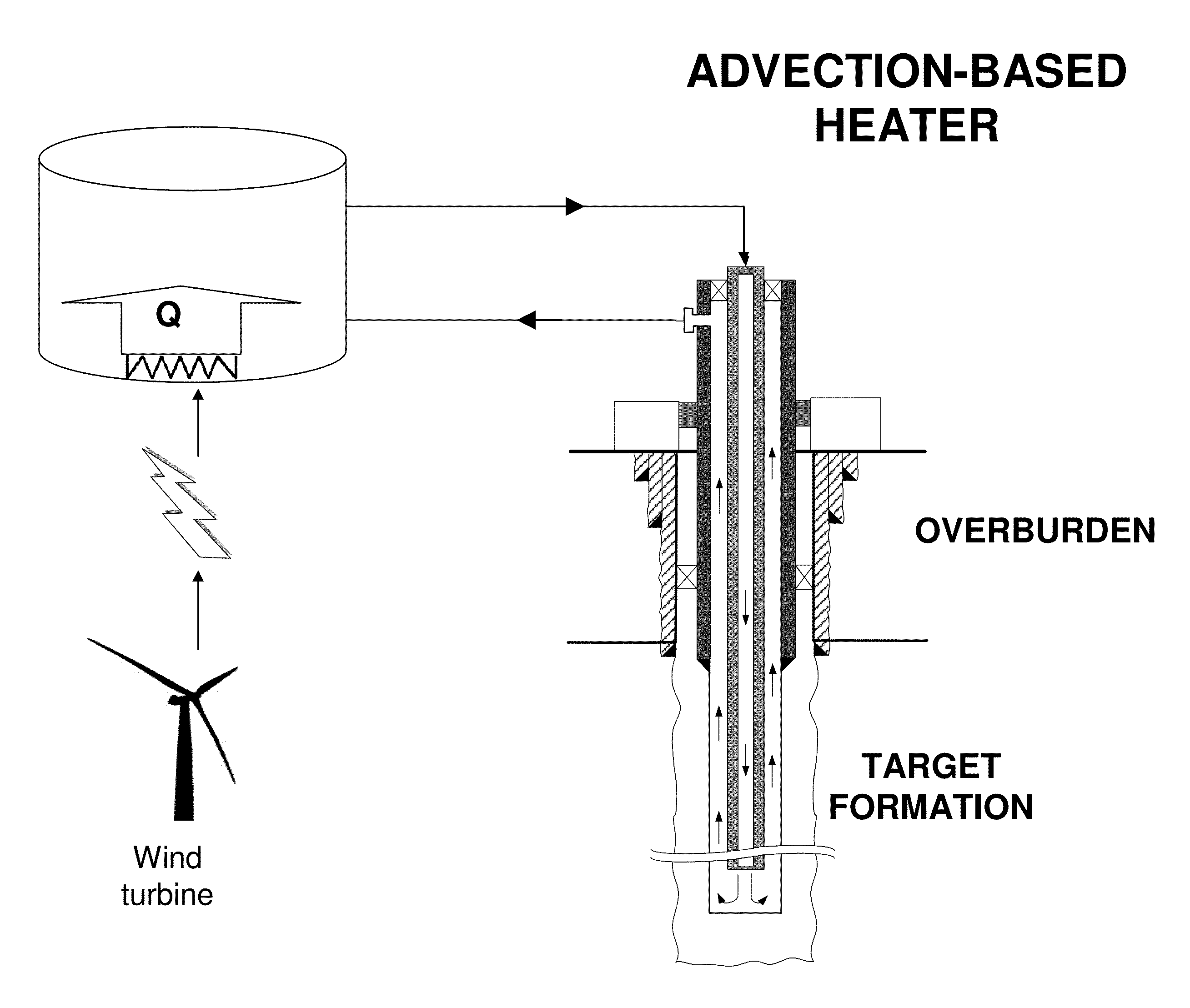

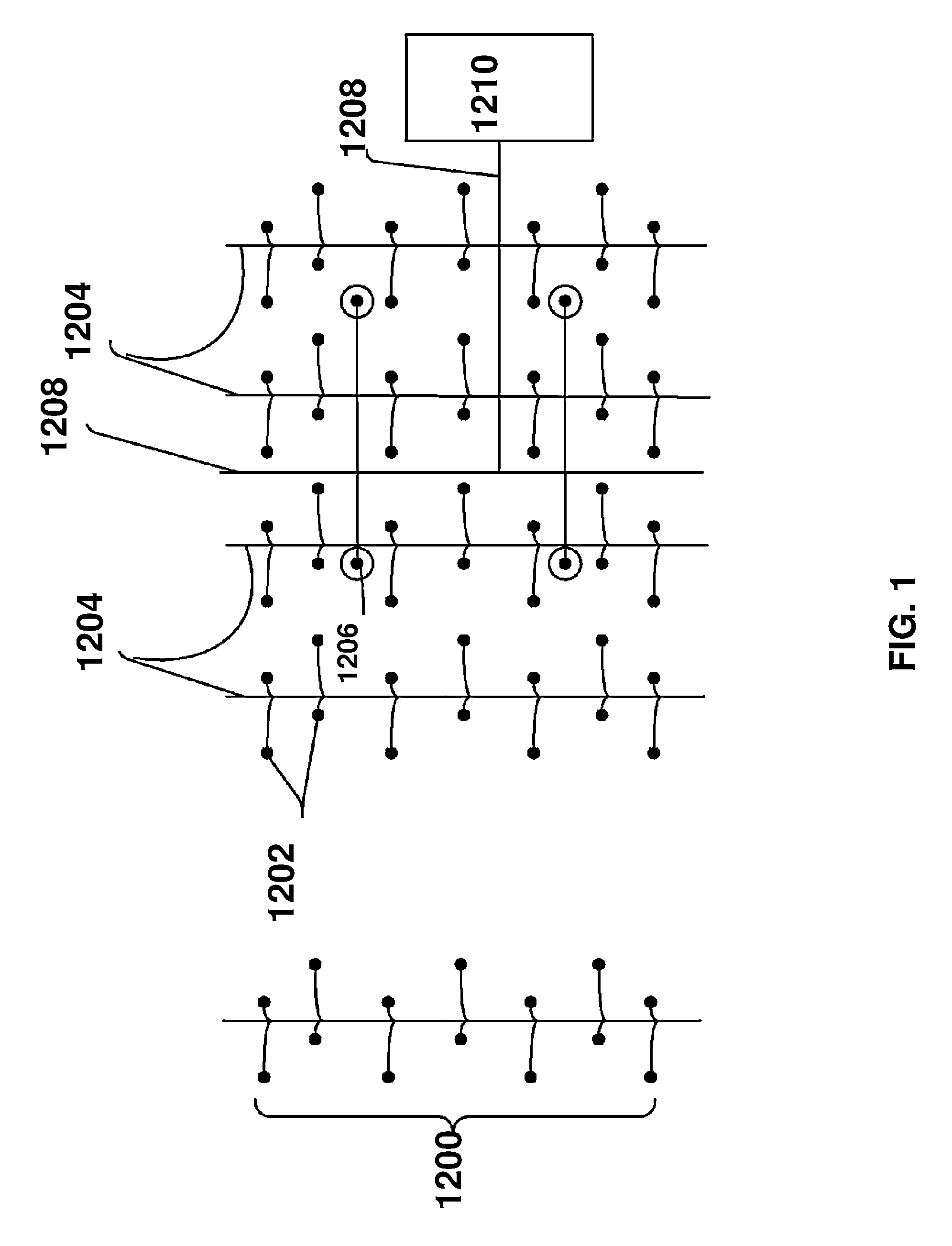

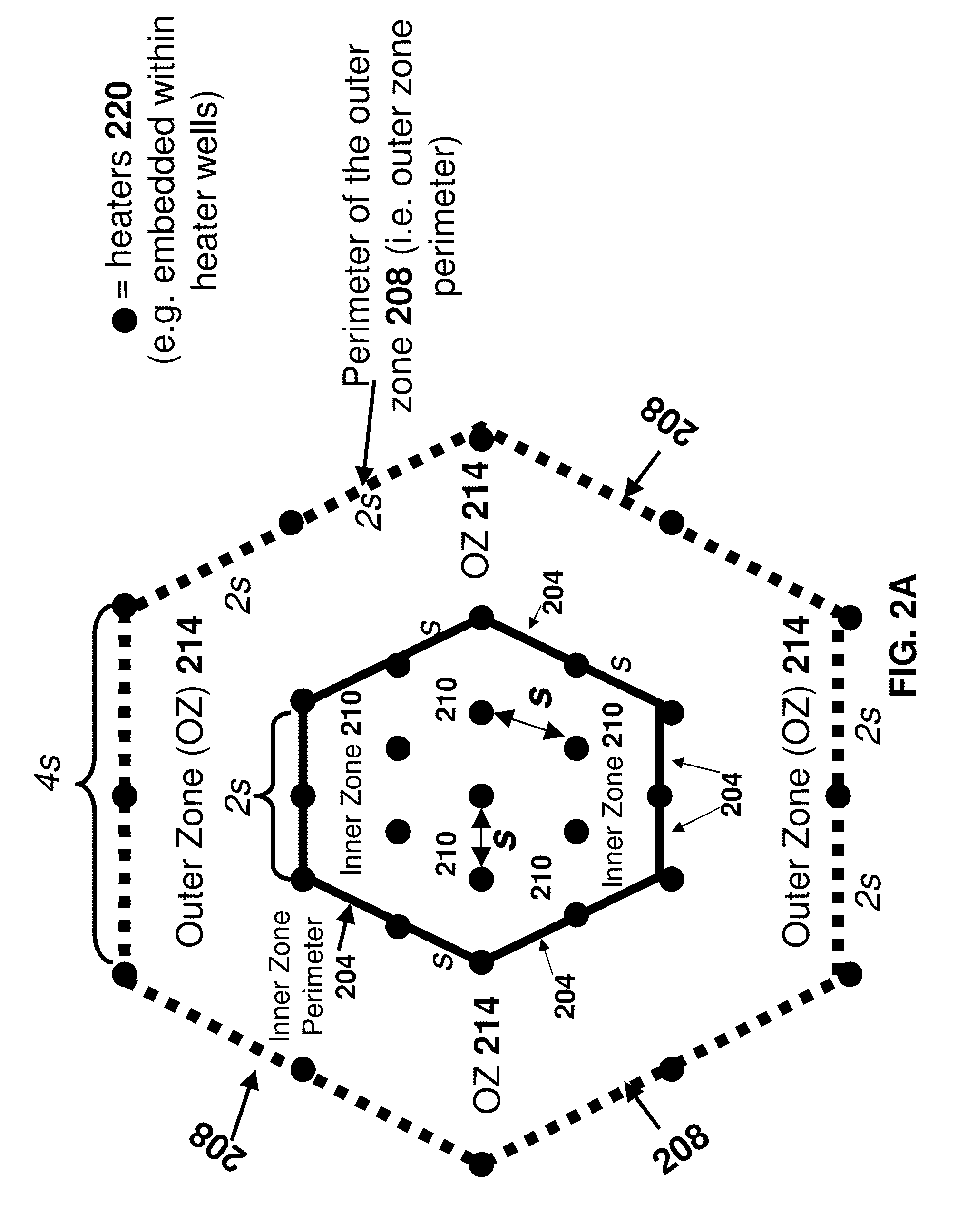

[0012]Embodiments of the present invention relate to heater patterns and related methods of producing hydrocarbon fluids from a subsurface hydrocarbon-containing formation (for example, an oil shale formation) where a heater cell may be divided into nested inner and outer zones. One or more heaters of the heater cell are powered primarily by electricity generated by wind. Production wells may be located within one or both zones. In the smaller inner zone, heaters are arranged at a relatively high spatial density while in the larger surrounding outer zone, a heater spatial density is significantly lower. Due to the higher heater density, a rate of temperature increase in the smaller inner zone of the subsurface exceeds that of the larger outer zone, and a rate of hydrocarbon fluid production ramps up significantly faster in the inner zone than in the outer zone.

[0013]The overall density of heaters in the heater cell, considered as a whole, is significantly less than that within the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com