Turbine bucket assembly and turbine system

a technology of turbine buckets and buckets, which is applied in the direction of liquid fuel engines, vessel construction, marine propulsion, etc., can solve the problems of limited operating capacity of such engines, and achieve the effects of reducing heat resistance, reducing heat expansion, and reducing heat resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

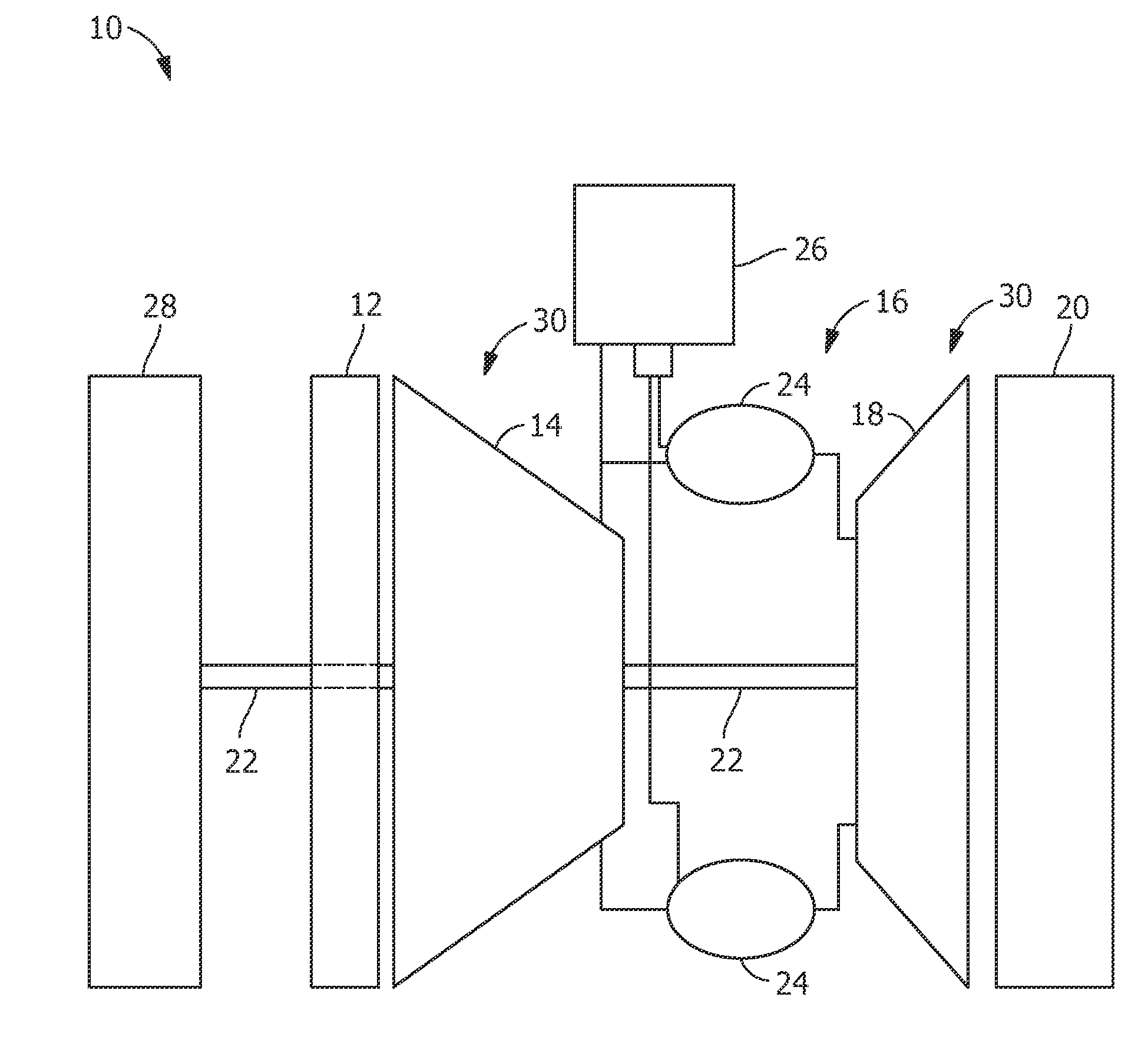

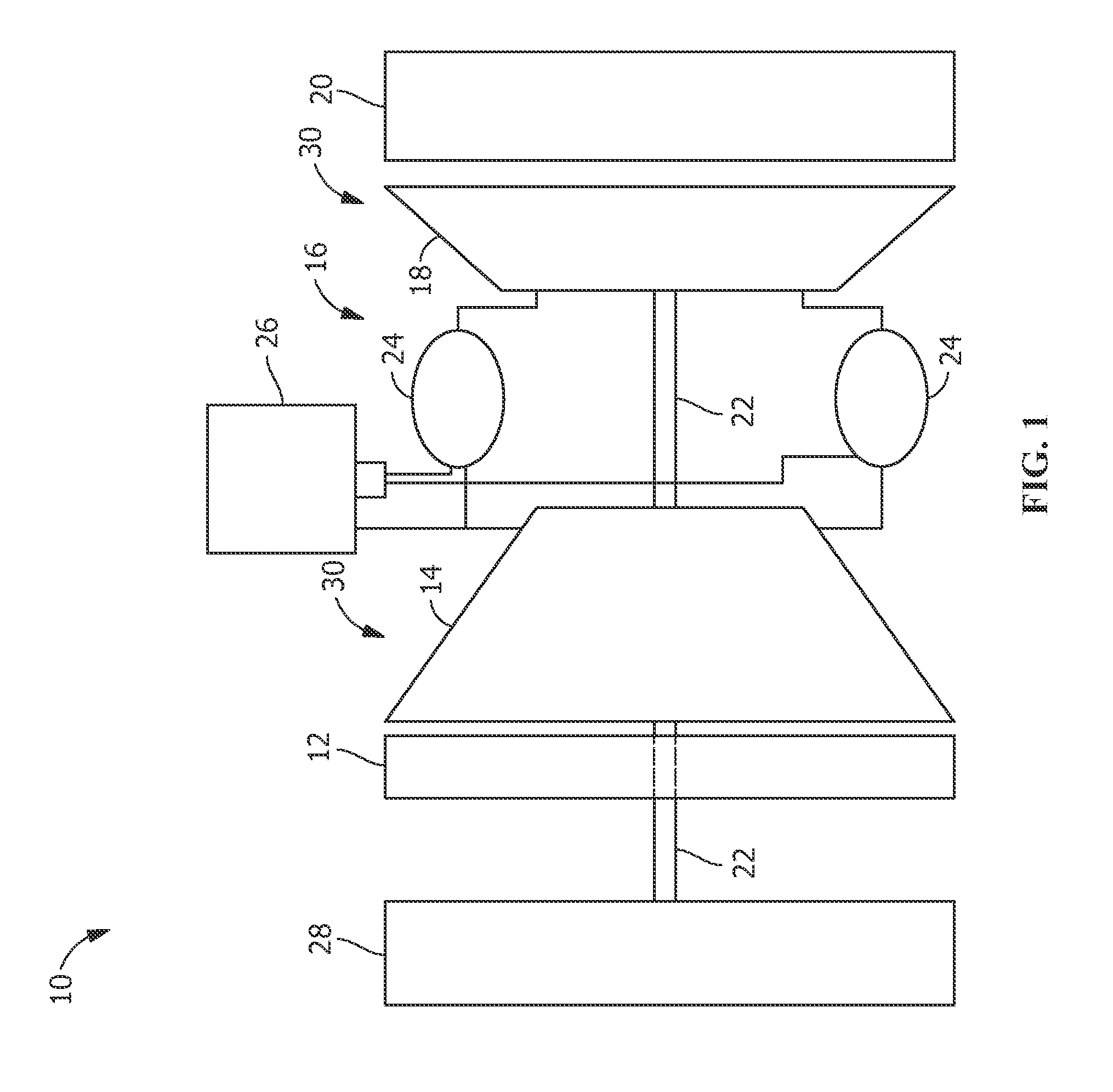

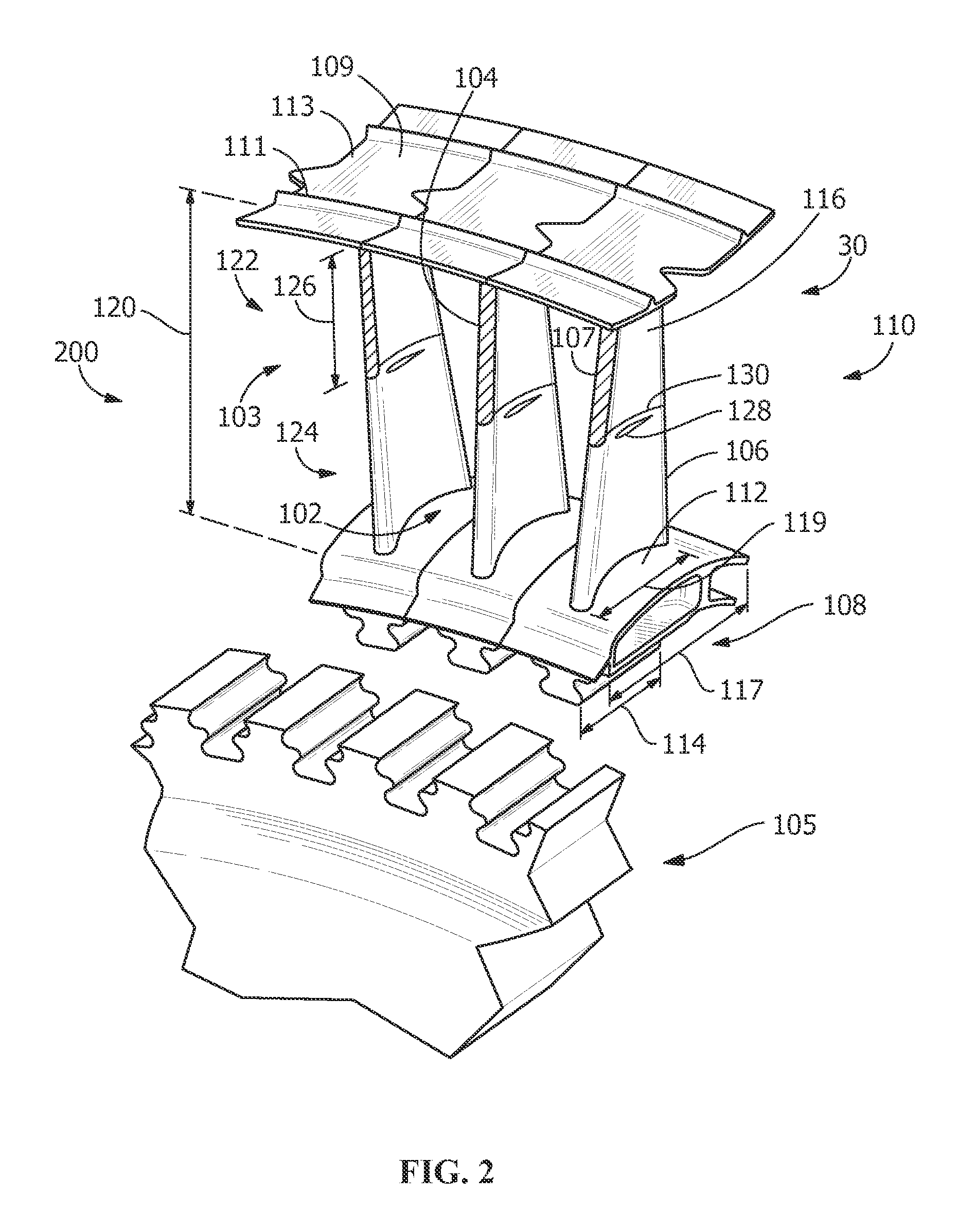

[0013]Provided is a turbine bucket assembly and a turbine system. In addition, methods of assembling and / or producing such turbine bucket assemblies and turbine systems are apparent from the disclosure. Embodiments of the present disclosure, for example, in comparison to similar concepts failing to include one or more of the features disclosed herein, permit easier repair of damage (for example, by a tip-rub event, overheating, and / or any other damaging event) by permitting the tip segment to be repaired alone without requiring more expensive and more time-consuming removal and repair / replacement of the complete turbine bucket, reduce overall operating and maintenance costs, reduce duration of out-of-service periods for repairs, permit other suitable advantages, permit larger or smaller sized engines and / or turbine buckets to be used, permit portions of a turbine bucket assembly to be exposed to higher temperatures, permit properties in a specific portion of a turbine bucket assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com