Blue collagenase assay

a blue collagenase and assay technology, applied in the field of blue collagenase, can solve the problems of inability to measure the activity of soluble or insoluble cell or tissue-associated collagenase, individually or in combination, and achieve the effect of improving the detection accuracy and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

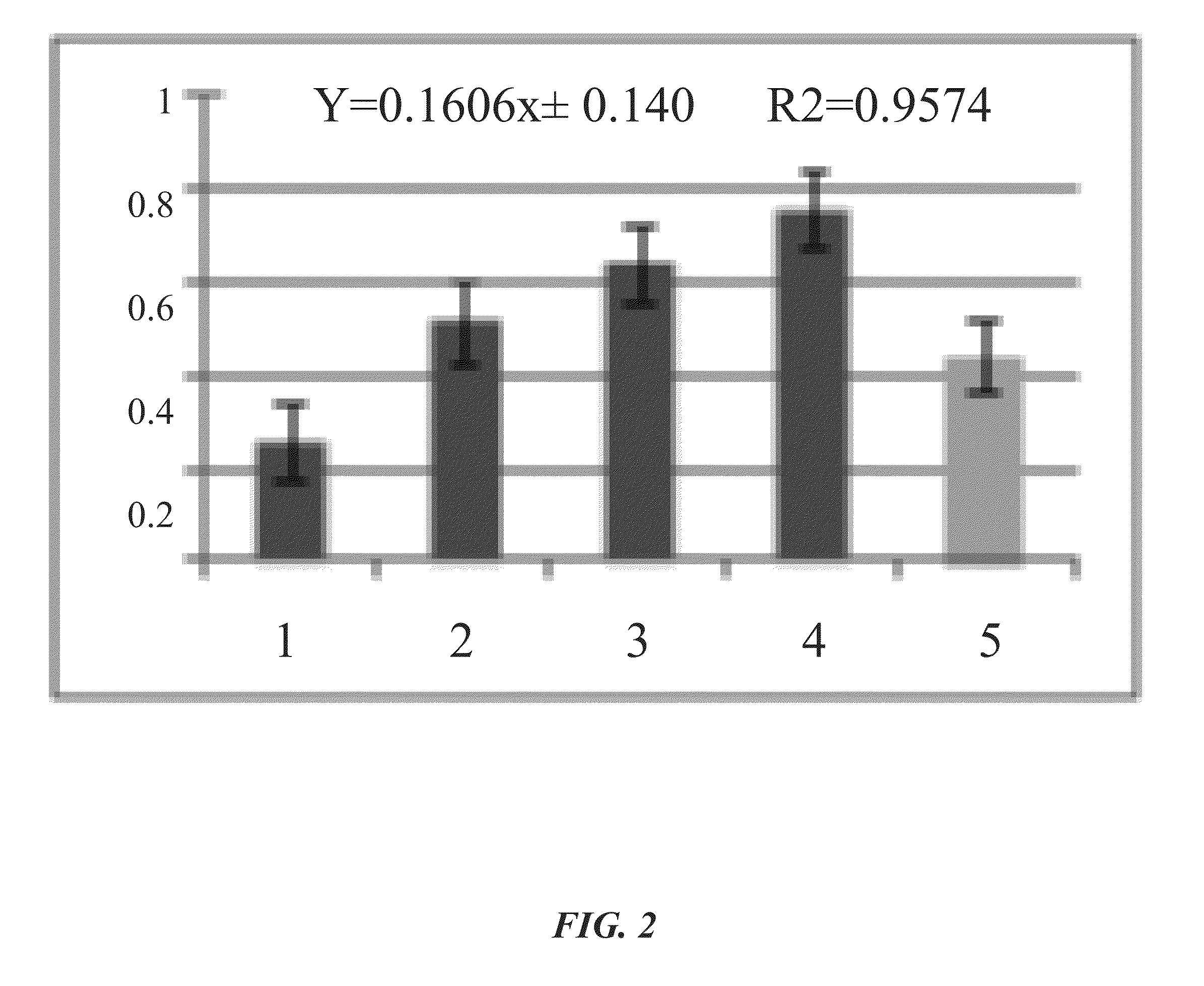

[0024]As an example, application of the blue collagenase assay to soluble Clostridium histolyticum collagenase (see FIGS. 1A-IB) and cell-associated Streptococcus mutans collagenase (see FIG. 2) is described herein.

[0025]The method generally includes the following steps:

[0026]1. The collagen fibrils are stained using Coomassie Brilliant Blue R-250 (C46-H44-N3-07-S2-Na).

[0027]2. The Blue collagen fibrils are suspended in collagenase substrate buffer (50 mM Tris, 50 mM NaCl, 10 mM CaCl2, pH7.5).

[0028]3. The blue collagen fibrils in suspension are incubated with the test sample at 37° C. on a rotator.

[0029]4. The collagenase activity results in the production of blue collagen particulates that can be readily observed.

[0030]5. After the incubation time of three (3) hours or longer, the mixture is filtered through glass wool / fibers to which the blue collagen fibrils are retained, and the small blue fragments are collected in the filtrate,

[0031]6, To determine the amount of digested colla...

example 2

1. Staining of Collagen

[0037]Type I fibrillar Collagen from Bovine Achilles Tendon (SIGMA-ALDRICH, product no. C9879) was cut with a pair of sharp scissors into shorter fibrils. The fibrils were passed through a 1 mm sieve and collected as dry collagen.

[0038]The dry collagen was mixed with 0.2% Coomassie Brilliant Blue in a solution of 10% acetic acid, 40% methanol in deionized water (standard method for staining protein bands in polyacrylamide gel), at a ratio of 500 mg collagen in 30 mL acetic acid-methanol-water solution, in a 50 mL conical centrifuge tube on a rotor at room temperature for 30 mins to 1 hour until all the collagen was saturated with the blue dye, after which time acetic acid-methanol-water (10:40:50) was added up to 50 mL.

[0039]The blue collagen suspension was centrifuged at 200×g for 2 minutes, and the supernatant was discarded. The excess dye was removed by rinsing with the solution of 10% Acetic acid, 40% methanol in deionized water.

[0040]With repeated mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com