High efficiency portable power plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

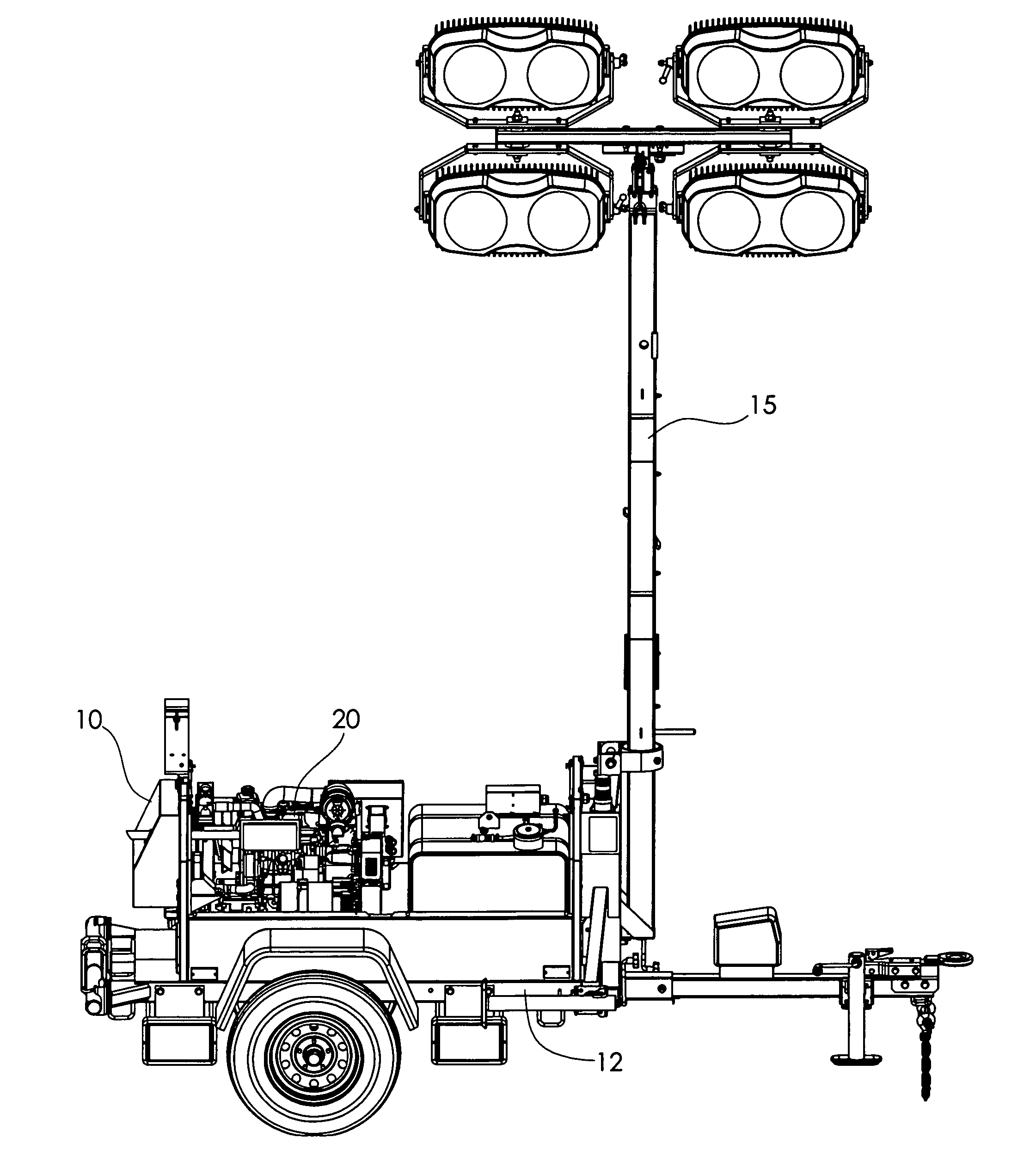

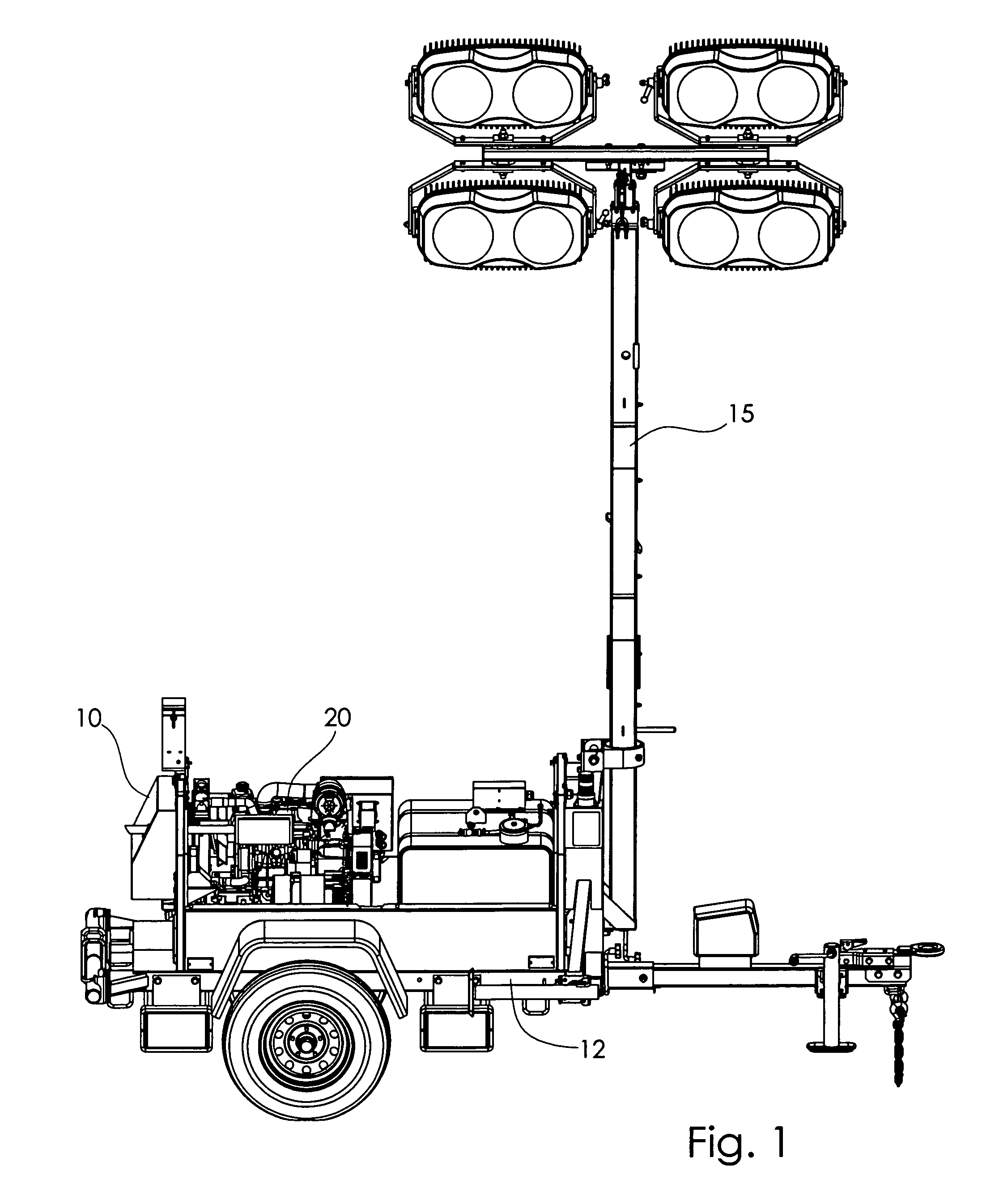

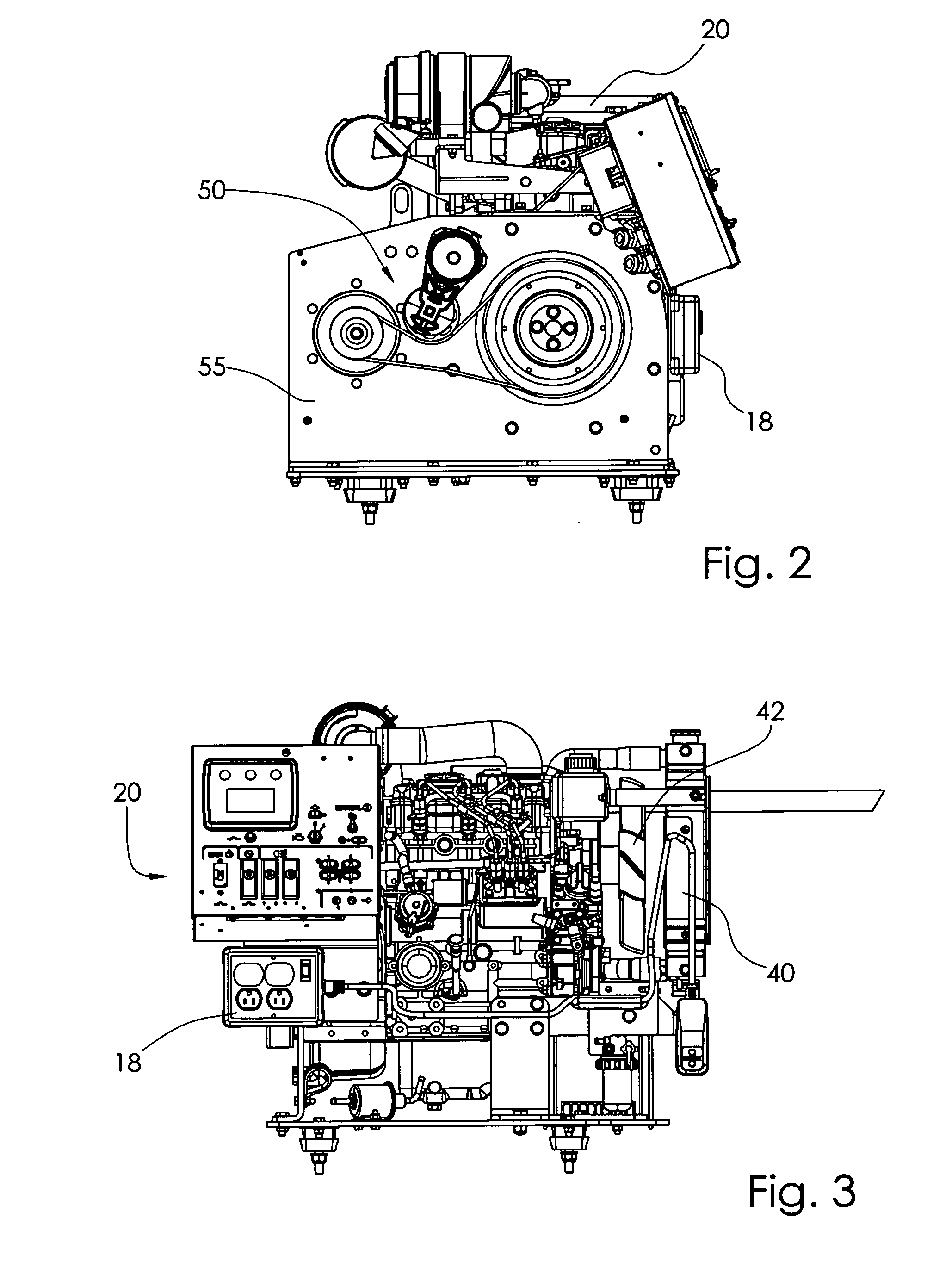

[0024]A portable electrical generating power plant 10 producing electrical power for the operation of electrical equipment, as shown in FIGS. 1-9 of the drawings, provides a portable transport trailer 12 upon which is mounted a high efficiency diesel engine 20 having a compact and light weight profile and having a low noise output, extended servicing intervals and the ability to produce and high power output, operating on a diesel or bio-diesel fuel, a belt drive and pulley system 50 providing a wide belt 90 drive between a large engine pulley 60 and a smaller generator pulley 70 attached to an electrical generator 30, and a coolant system 40 to maintain a constant operational temperature regardless of the environmental temperature within which the power plant 10 is operated, wherein the engine 20 is operated at a lower rpm while maintaining a high rpm on the generator pulley 70, extending the operational time of the engine 20, producing minimal 1600 watts at 60 Hz of electrical sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com