Low voltage differential signaling (LVDS) driving circuit

a driving circuit and low voltage technology, applied in logic circuit coupling/interface arrangement, logic circuit coupling/interface using field-effect transistors, pulse techniques, etc., can solve the problems of insufficient head room of current sources and very limited output range of differential signaling circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]In order to illustrate the purposes, features and advantages of the invention, the embodiments and figures of the invention are described in detail as follows.

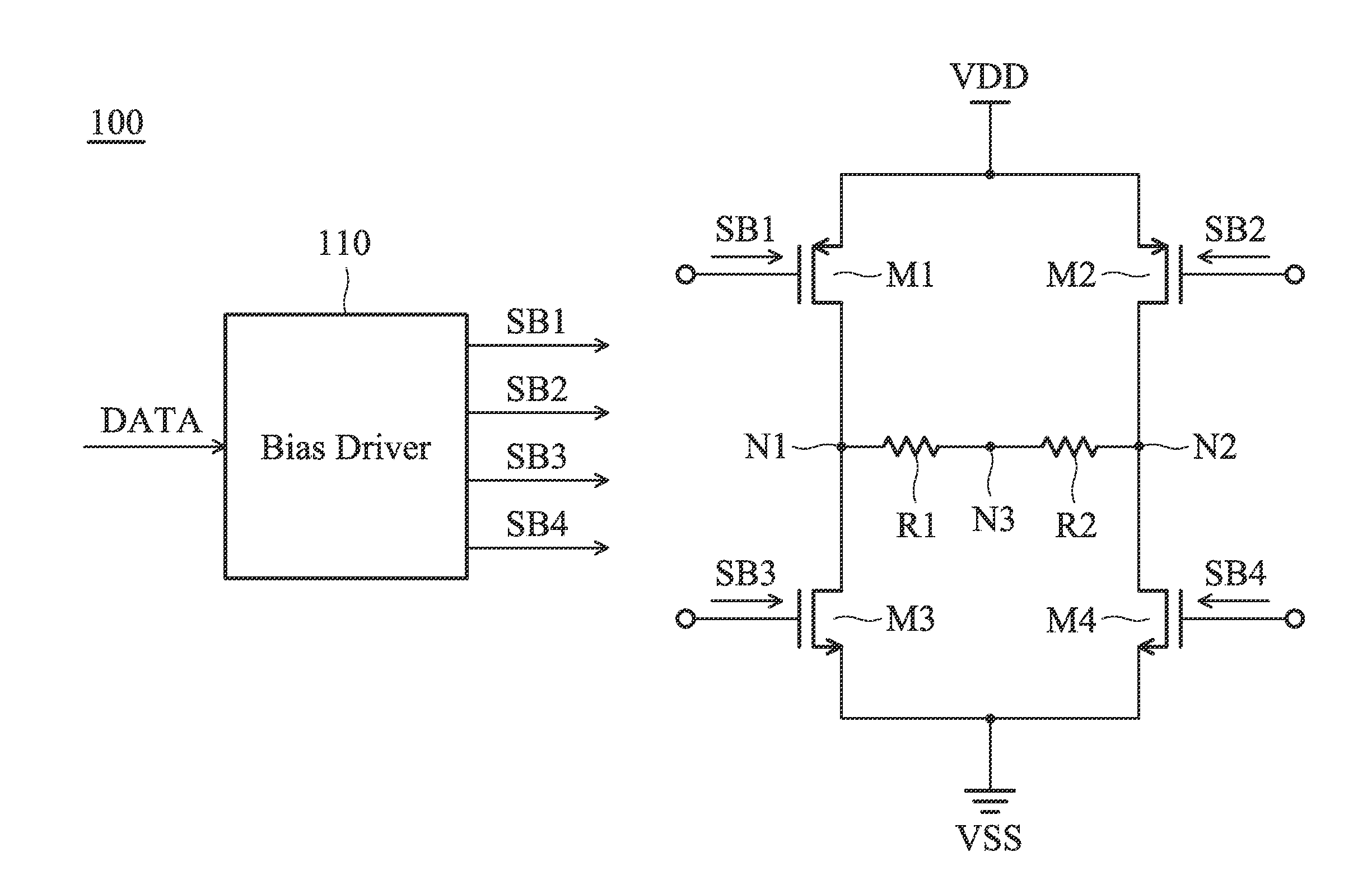

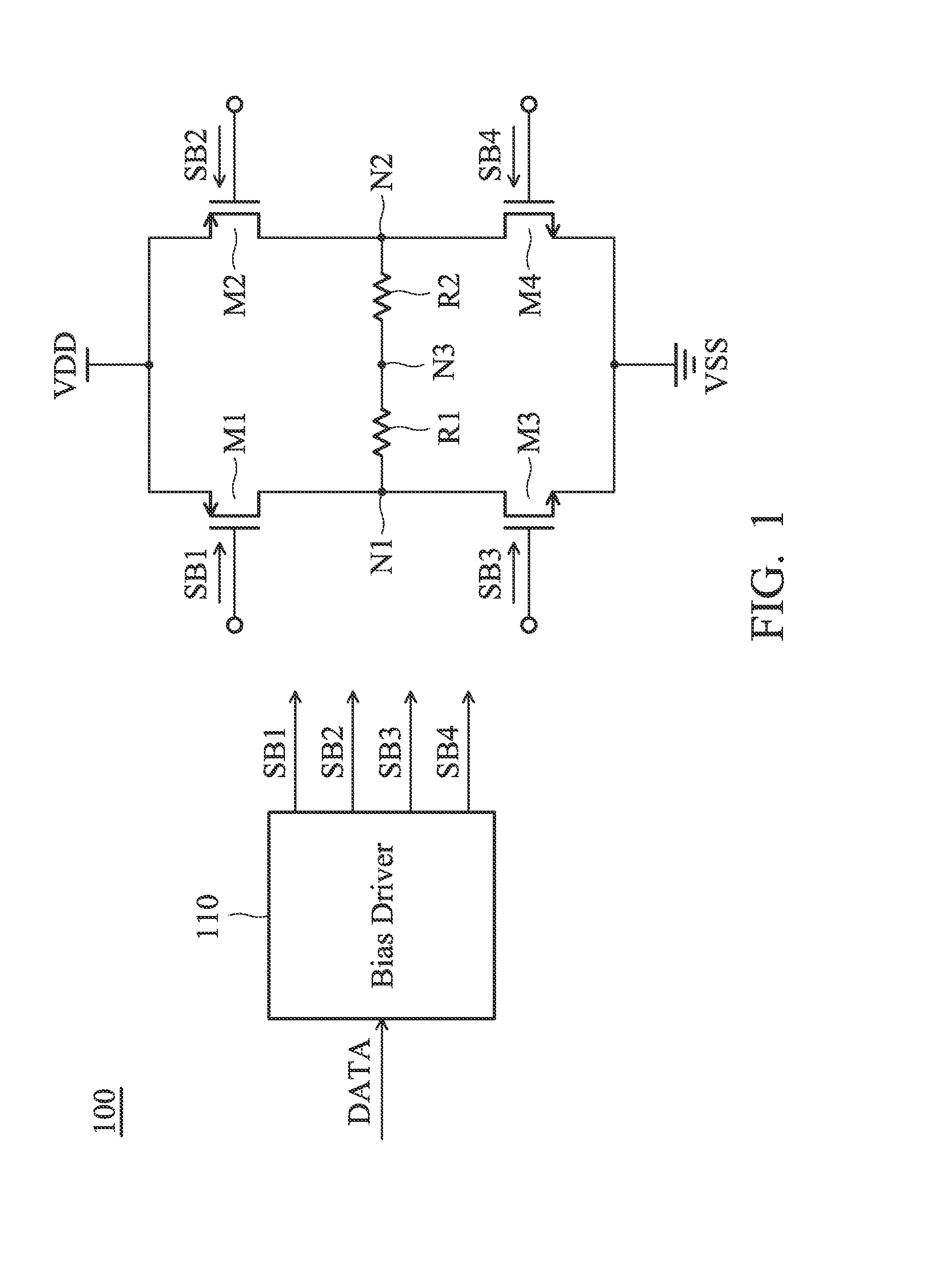

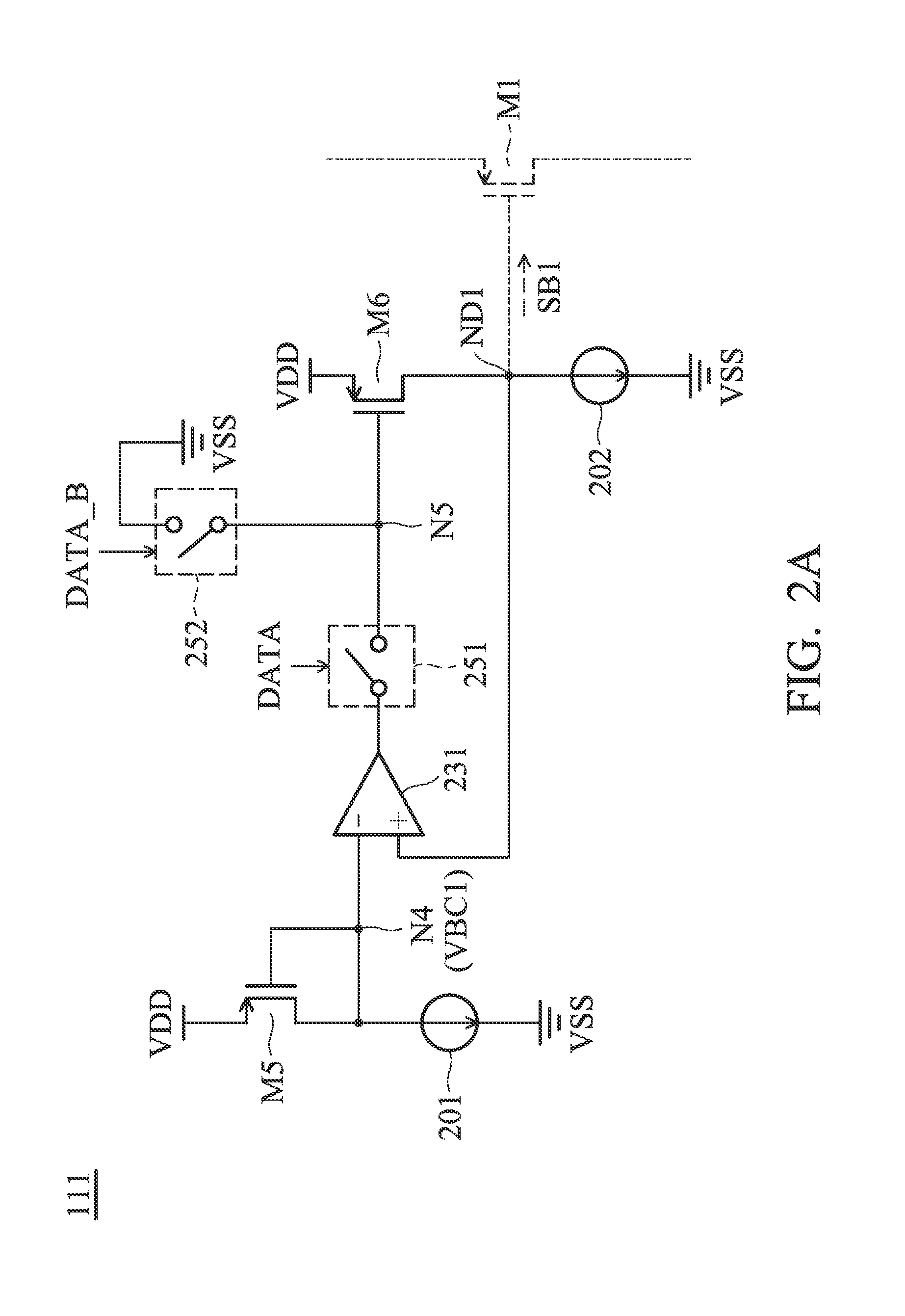

[0050]FIG. 1 is a diagram of an LVDS (Low Voltage Differential Signaling) driving circuit 100 according to an embodiment of the invention. The LVDS driving circuit 100 includes a first transistor M1, a second transistor M2, a third transistor M3, a fourth transistor M4, a first resistor R1, a second resistor R2, and a bias driver 110. The bias driver 110 generates a first bias signal SB1, a second bias signal SB2, a third bias signal SB3, and a fourth bias signal SB4 for controlling the first transistor M1, the second transistor M2, the third transistor M3, and the fourth transistor M4, respectively, according to a data signal DATA. The data signal DATA may be a digital signal. In some embodiments, the first transistor M1 and the second transistor M2 are PMOS transistors (P-type Metal Oxide Semiconductor Field Effect Tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com