Composite structural member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Assessment of Three Member Beam, and Comparison with Two Member Beam

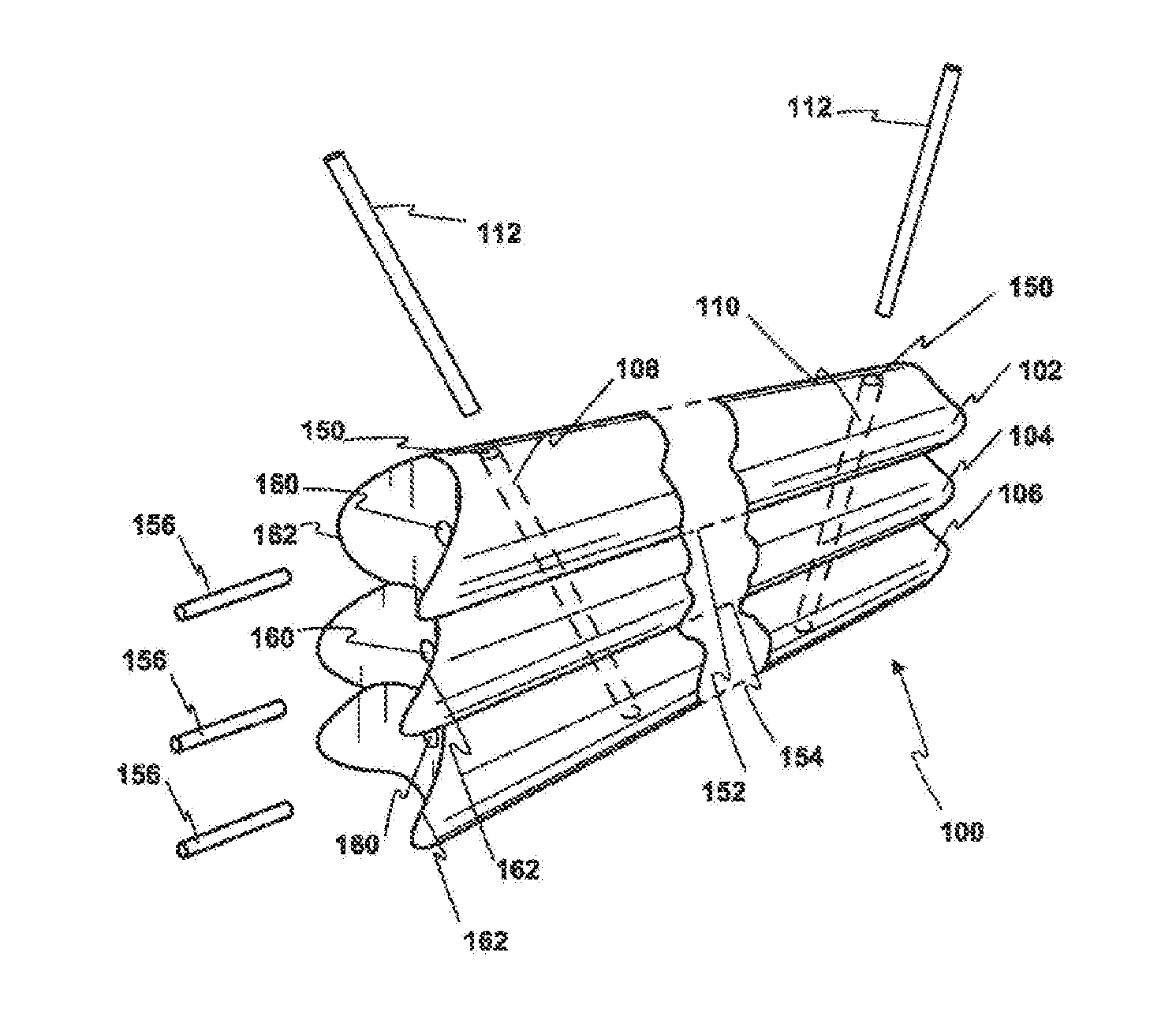

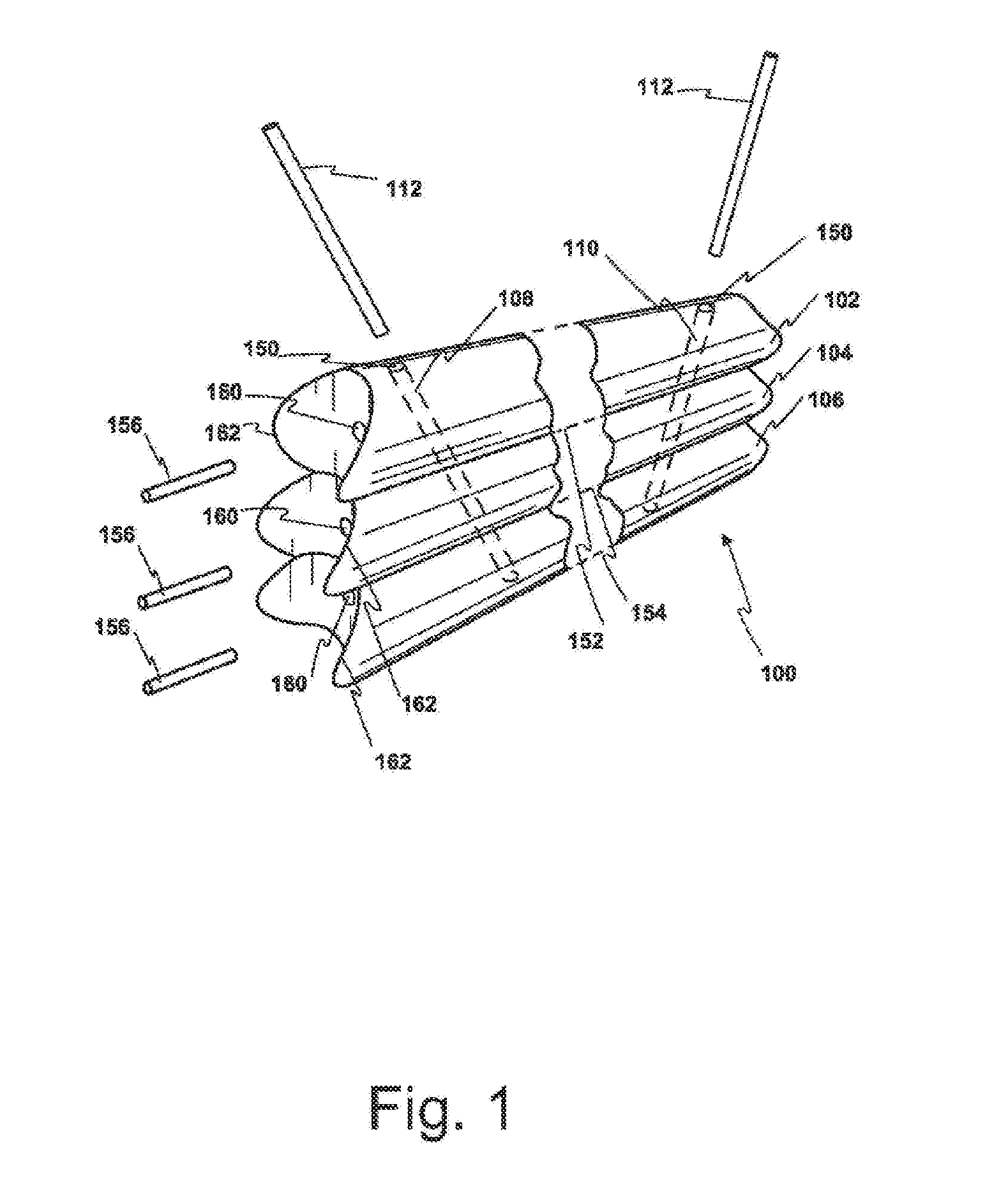

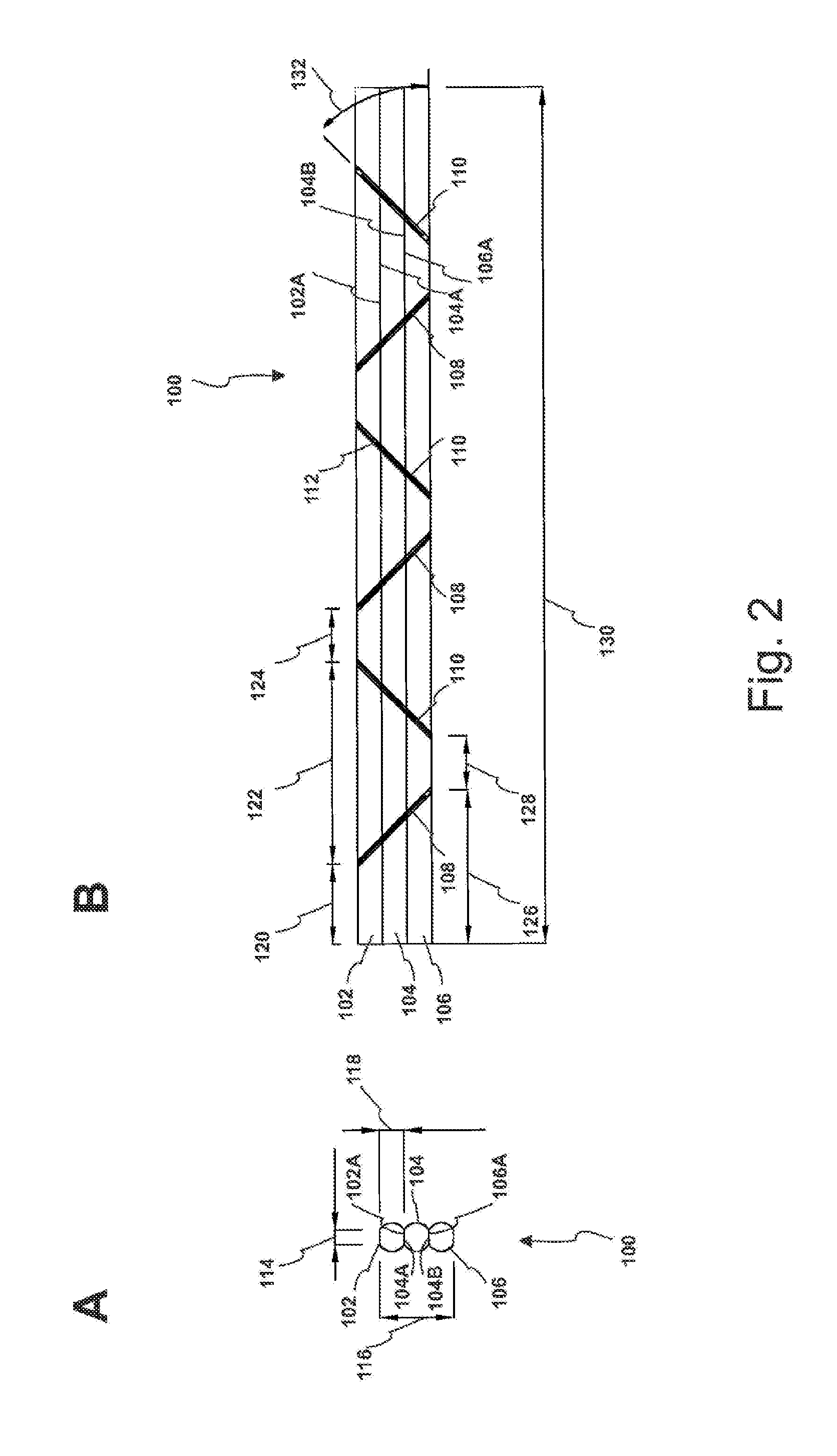

[0149]A beam produced generally in accordance with the preferred embodiment above, by using three 80 mm members. This beam was compared with a beam produced generally according to PCT / AU20091001453, by using two members of 100 mm. In both beams, fasteners were inserted alternately acutely and obtusely in a repeating V-shaped manner.

[0150]Both beams passed on strength criteria as a joist at 600 ctrs at 3.6 metre span.

[0151]Under service conditions the three member beam shows an acceptable 50% stress (F11 is 35 Mpa, and F34 is 100 Mpa).

[0152]This example demonstrates the usefulness of smaller timber rounds fabricated from wood which has previously been discarded or converted into low value products such as wood chips. Forming the smaller rounds into a three member beam using the fastening methods specified herein provides a higher value product having acceptable structural characteristics.

example 2

Cost Benefit of Three Member Beams

[0153]Applicant proposes that when using the same diameter logs with stiffness defined by reference to the moment of inertia (I=bd3 / 12), and assuming that stiffness is related to strength, and deflection is the limiting factor:

[0154]It will be noted in the above equation that b is a constant (being the width of beam), and so it is possible to compare d3 for 1, 2, 3, 4 or more members.

[0155]For example, when considering a 10 cm diameter member. (80 cm between flats): when going from a beam having 2 members (prior art) to 3 members (a beam according to the present invention) the I values will be 16 cm3 compared to 24 cm3, giving a ratio of 4096:13824. This is an advantage of almost 3.3 to 1.

[0156]In light of the above it is proposed that around 50% increase in costs provides 3.3 times the strength of the prior art two member beam.

example 3

Beam Composed of Four Members

[0157]Four peeler cores (each of only 46 mm diameter) where cut to remove a slab from opposing surfaces. The slabbed cores had a first dimension of 40 mm (taken from the first planar face formed from slabbing to the second diametrically opposite planar face), and a second dimension of 184 mm. The planar faces formed cooperating surfaces where two rounds contacted. An end-on view of the assembled composite member is shown in FIG. 4. The length of the composite member was 2200 mm.

[0158]Analysis yielded the following parameters:

Area:6306.2195 sq inPerimeter:432.8113 in.Bounding boxX: −23.0769 - 23.0709 inY: −79.9408 - 79.9408 inCentroidX: 0.0000 inY: 0.0000 inMoments of inertiaX: 13310559.5729 sq in sq inY: 880519.8341 sq in sq inProduct of inertiaXY: 0.0000 sq in sq inRadii of gyrationX: 45.9424 inPrincipal moments (sq in sq in)I: 880519.8341 along [0.0000-1.0000]and X-Y directions aboutcentroid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com