Automatic stuffing-injecting food processing mechanical equipment

A technology of food processing and mechanical equipment, applied in food science, baking, household utensils, etc., can solve many problems, short life, serious dripping problems, etc., and achieve the effect of accelerating work efficiency, long service life, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

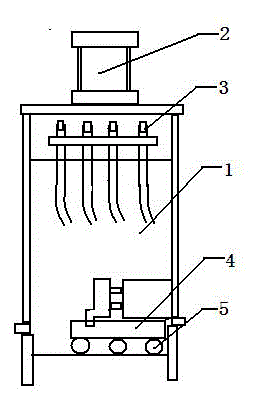

[0013] This embodiment provides an automatic stuffing food processing machinery, characterized in that: the stuffing food processing machinery includes a stuffing cylinder (1), a compression device (2), an outlet (3), a connecting rod (4 ), runner (5);

[0014] Among them: a rotatable runner (5) is set on the bottom plate of the stuffing tube (1), a connecting rod (4) is arranged on the runner (5), and an outlet with a piston ( 3) With the filling tube, there is a press-in hole at the bottom of the tube, a suction hole is opened on the outer bottom plate of the tube, and a filling hole is opened at the bottom of the bottom plate at the same time. Automatic operation of material and injection.

[0015] A plurality of filling tubes are arranged in the filling tube, the same number of suction holes are arranged on the bottom plate, and a plurality of runners (5) are arranged.

[0016] The runner (5) is extended on the outside of the stuffing tube (1) and connected to a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com