Vertical xmas tree and workover assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]While the invention has been described in general terms above, a more detailed and non-limiting example of embodiment is presented in the following with reference to the drawings, in which

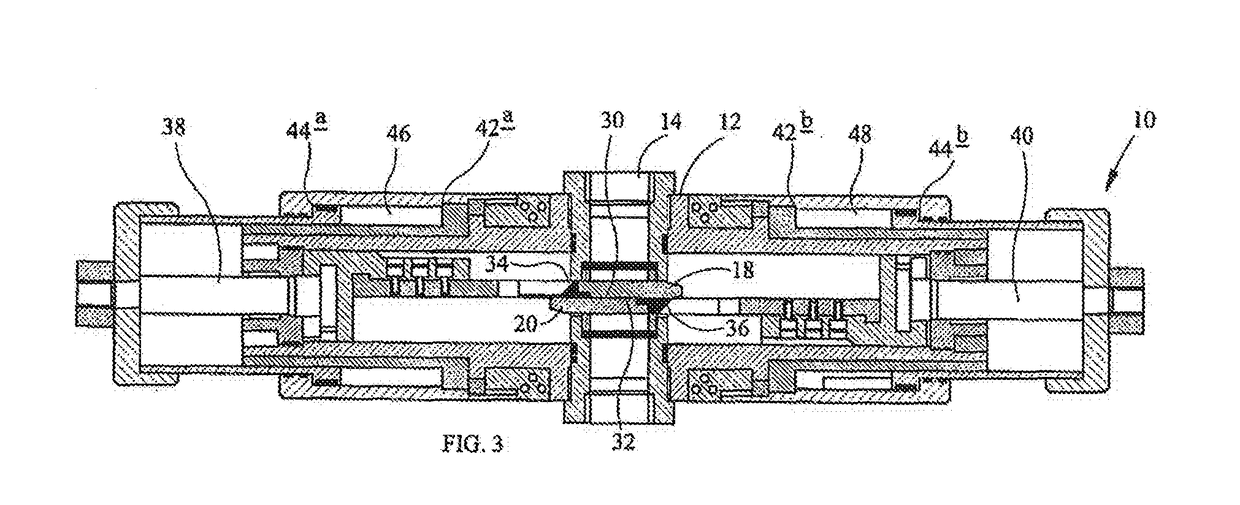

[0030]FIG. 1a is a cross section view of a prior art gate valve in an open position;

[0031]FIG. 1b is a cross section view of the valve in FIG. 1a in a closed position;

[0032]FIG. 1c is an enlarged cross section view of the valve in FIG. 1b;

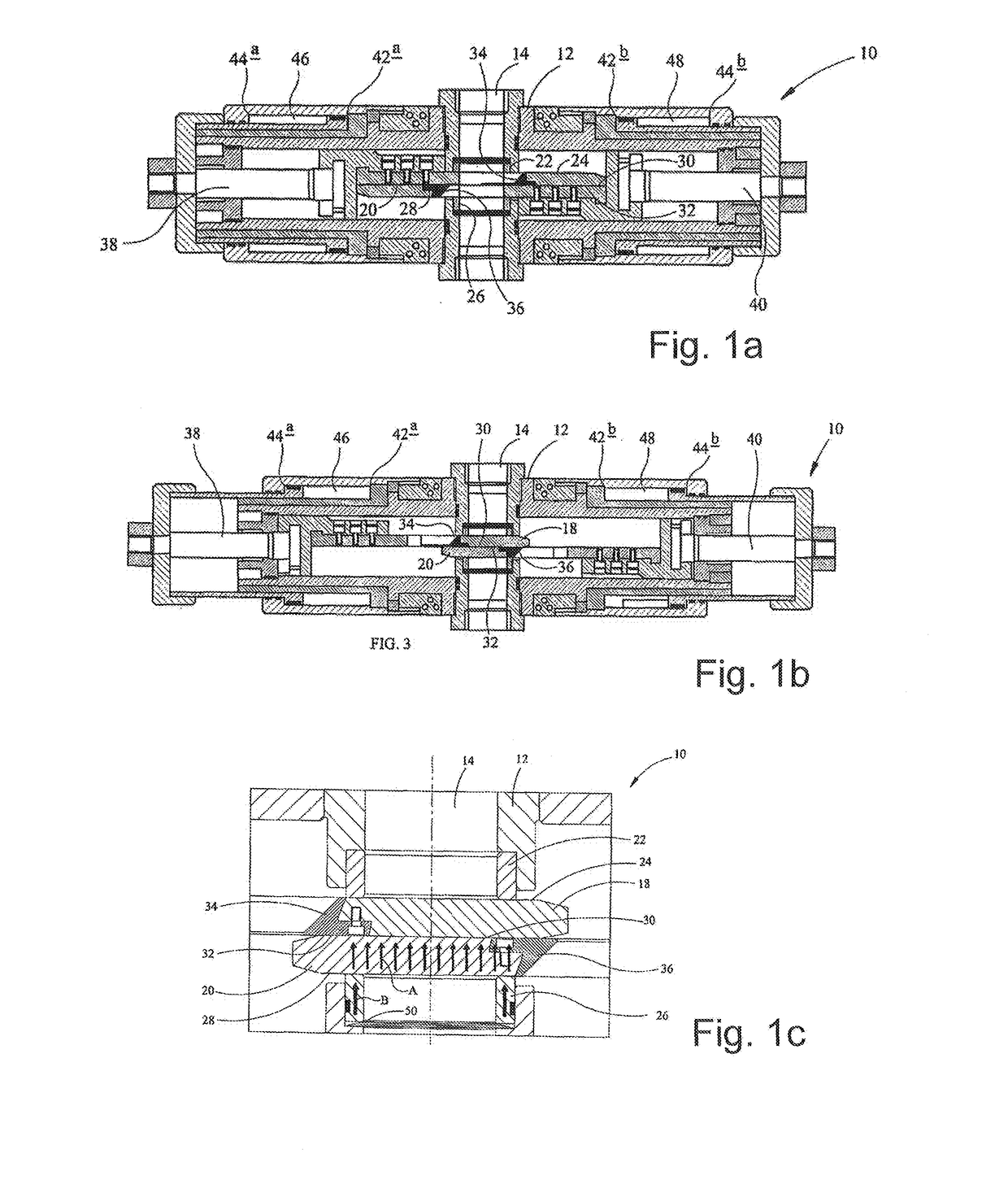

[0033]FIG. 2 is a schematic overview of a floating surface installation performing workover operation in a subsea well;

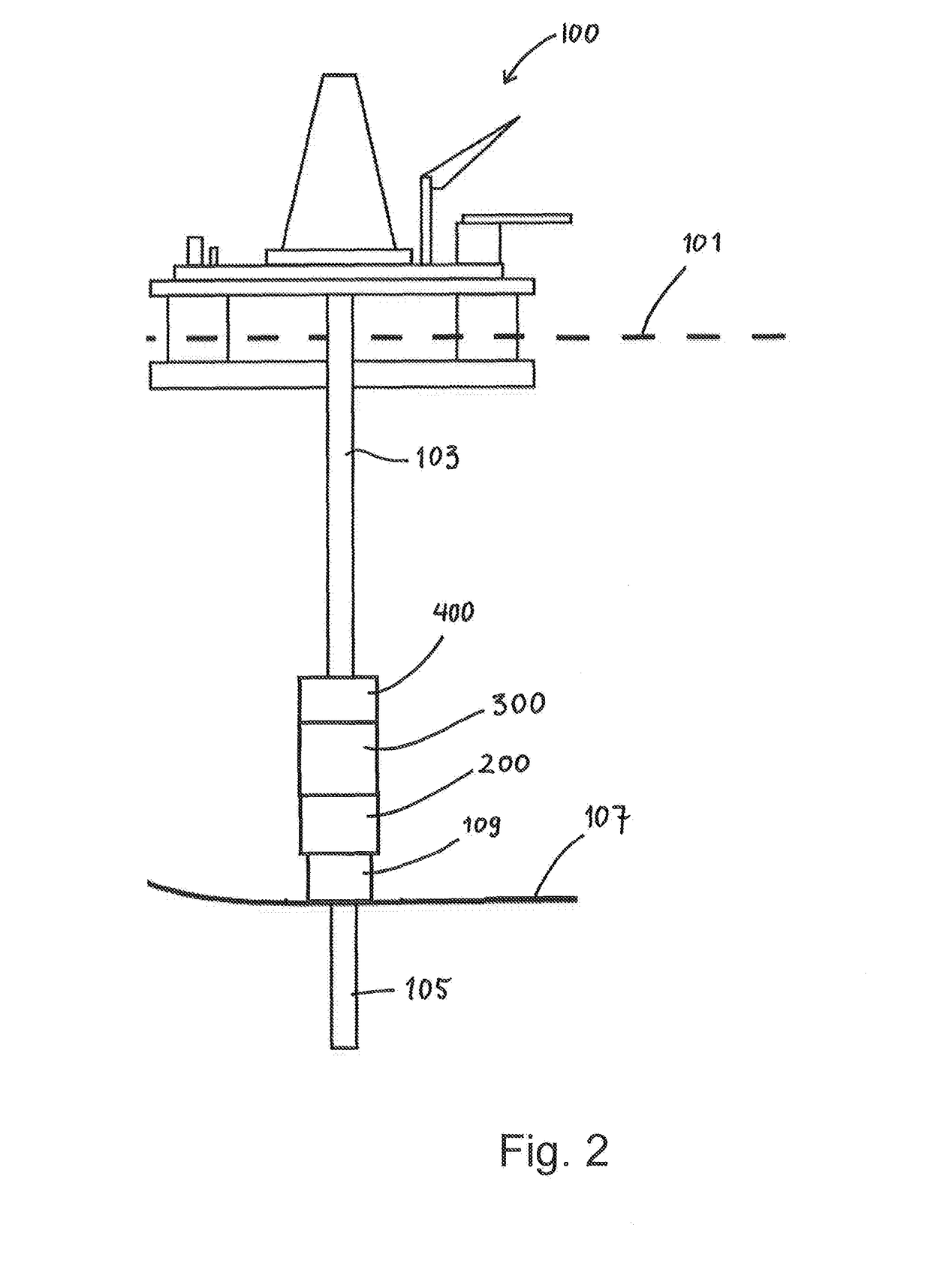

[0034]FIG. 3 is a principle view of a workover setup according to prior art;

[0035]FIG. 4 is a principle view according to FIG. 3, however illustrating a setup according to the present invention; and

[0036]FIG. 5 is a principle view of a vertical Xmas tree in the process of landing on a subsea wellhead.

[0037]FIG. 1a to FIG. 1c illustrate a known valve 10 which is suited for well control of a subsea hydrocarbon well. FIG. 1a a shows the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com