Enclosure for modular construction systems

a modular construction and enclosure technology, applied in the field of construction, can solve the problems of limiting work, high time consumption of operators, and consequently more expensive labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]An example of a preferred embodiment of the invention is described below with reference to the above-cited figures, without limiting or reducing the scope of protection of the present invention.

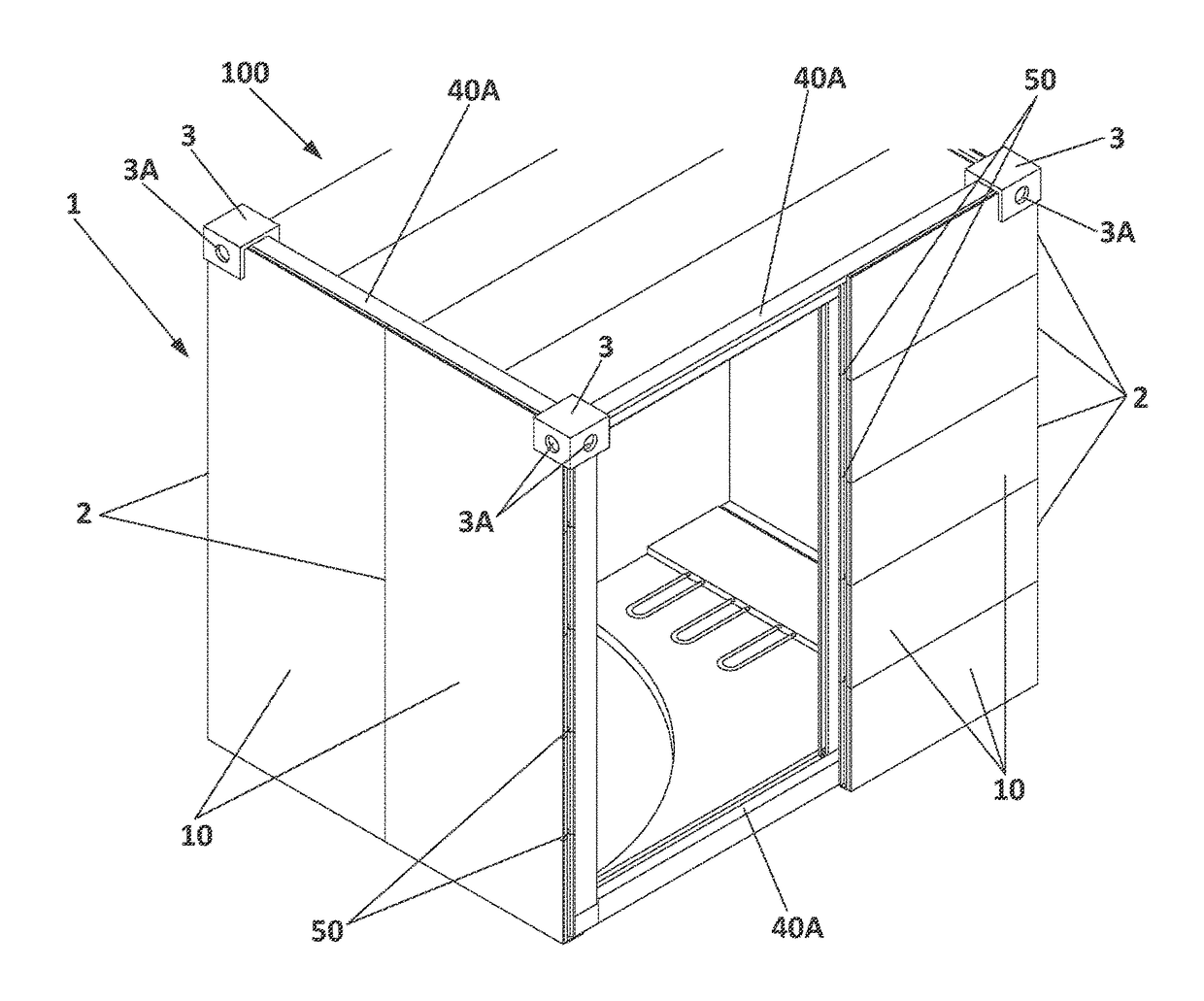

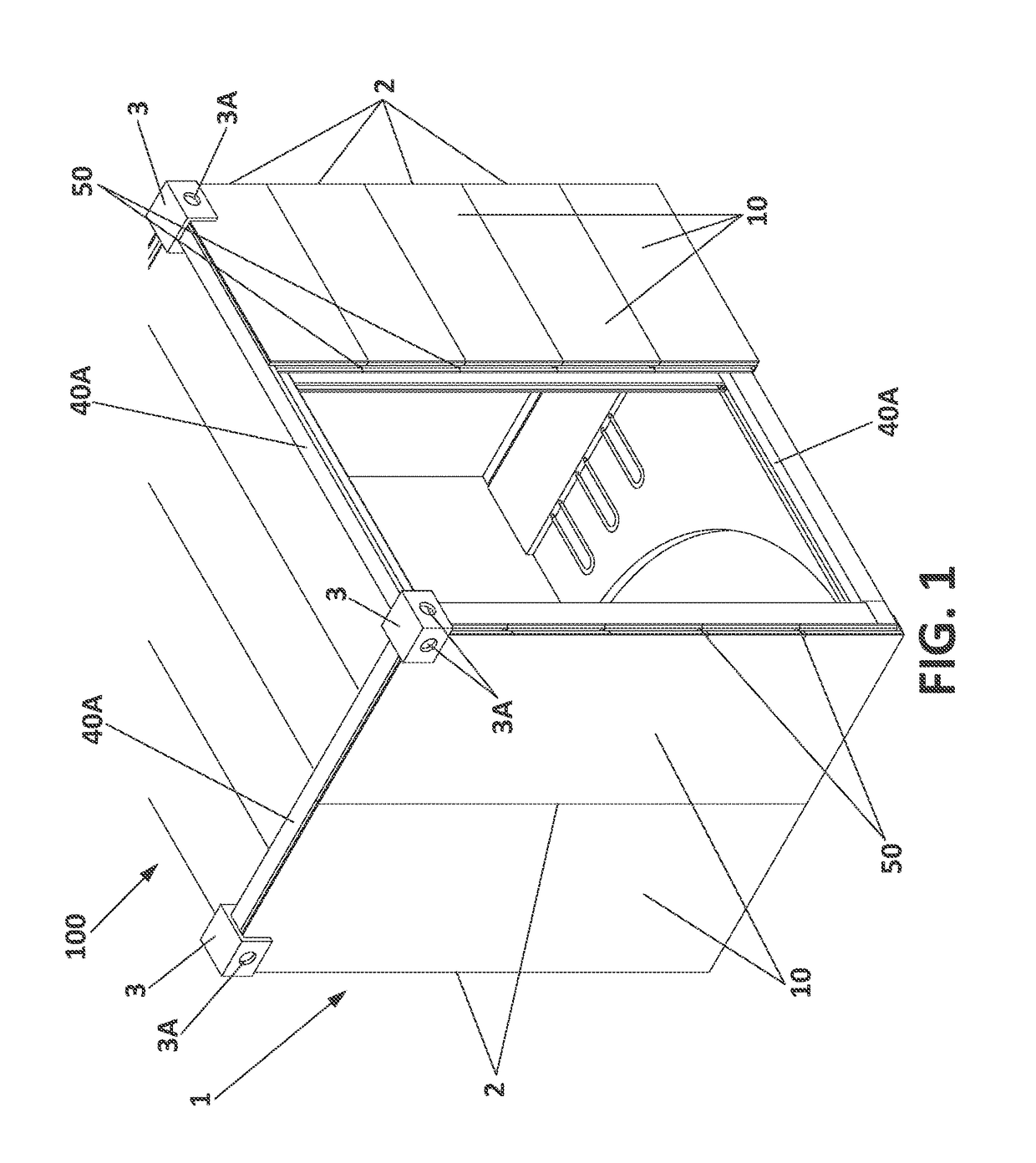

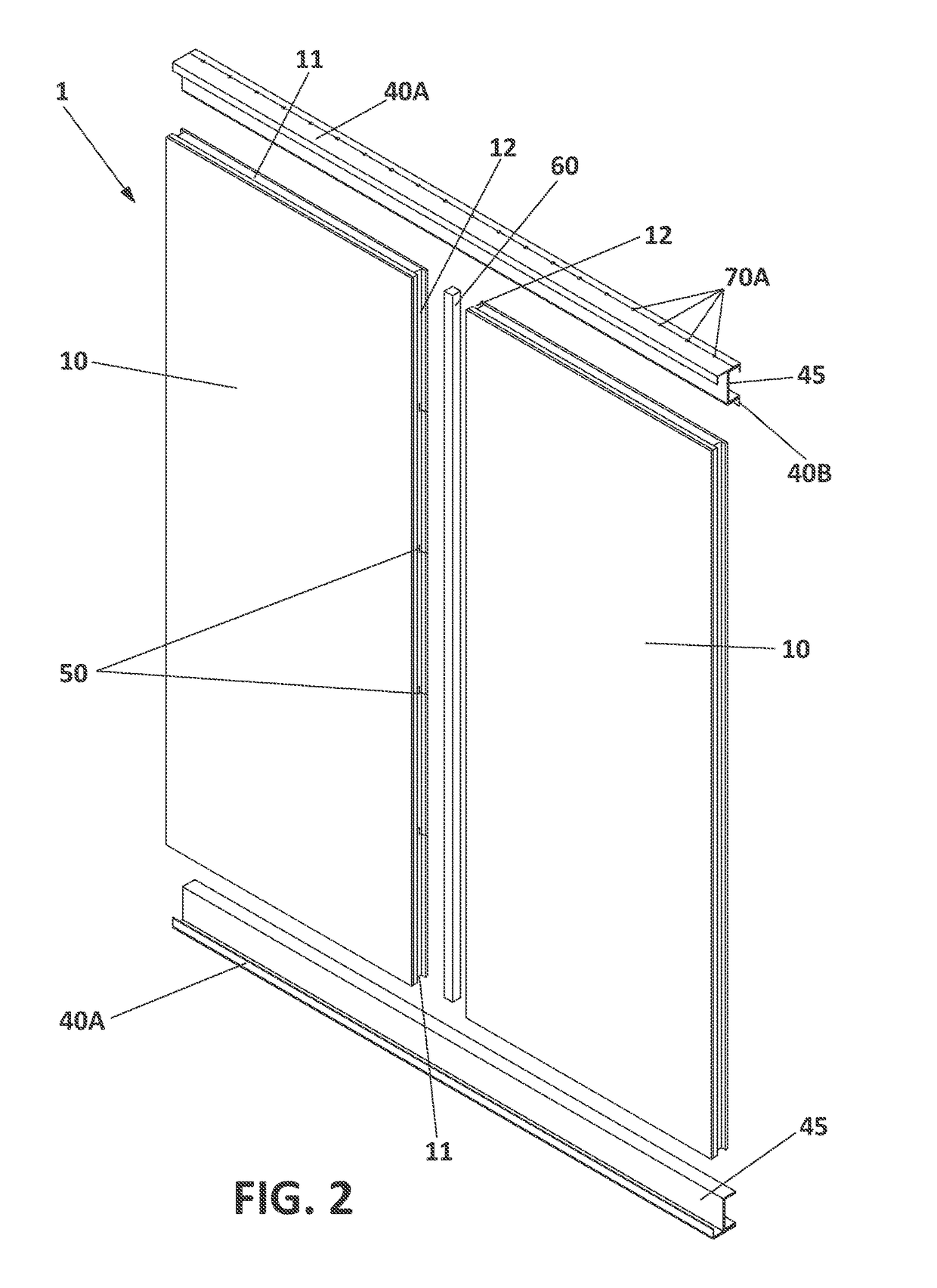

[0032]A modular construction (100) made up by the enclosure (1) of the invention, and which comprises a plurality of panels (2) having a tongue and groove joint (50) at their upper, bottom and side edges, as shown in FIGS. 1 and 2, for coupling together to form a vertical column of panels (2), as depicted in FIG. 1, can be seen in FIG. 1.

[0033]More specifically, each of said panels (2) are formed in turn by a multilayer outer piece (10), a multilayer inner piece (20), and an intermediate air chamber (30) arranged between the outer and inner pieces (10, 20), as reflected in FIGS. 3 and 4. At this point, FIGS. 5, 6A and 6B should be mentioned where, in addition to the various components and inner pieces of the panels (2) cited above, a top view of the connection between two panels (2) can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com