Apparatus and Process for the Improved Economic Extraction of Metal from a Metal-Bearing Material

a metal-bearing material and economic extraction technology, applied in the direction of process efficiency improvement, etc., can solve the problems of affecting the economic and social benefits of mining, affecting the economic benefits of mining, so as to reduce the capital, simplify the design of the reaction vessel, and reduce the effect of capital

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Economic Extraction of Copper from a Copper-Bearing Feed Material

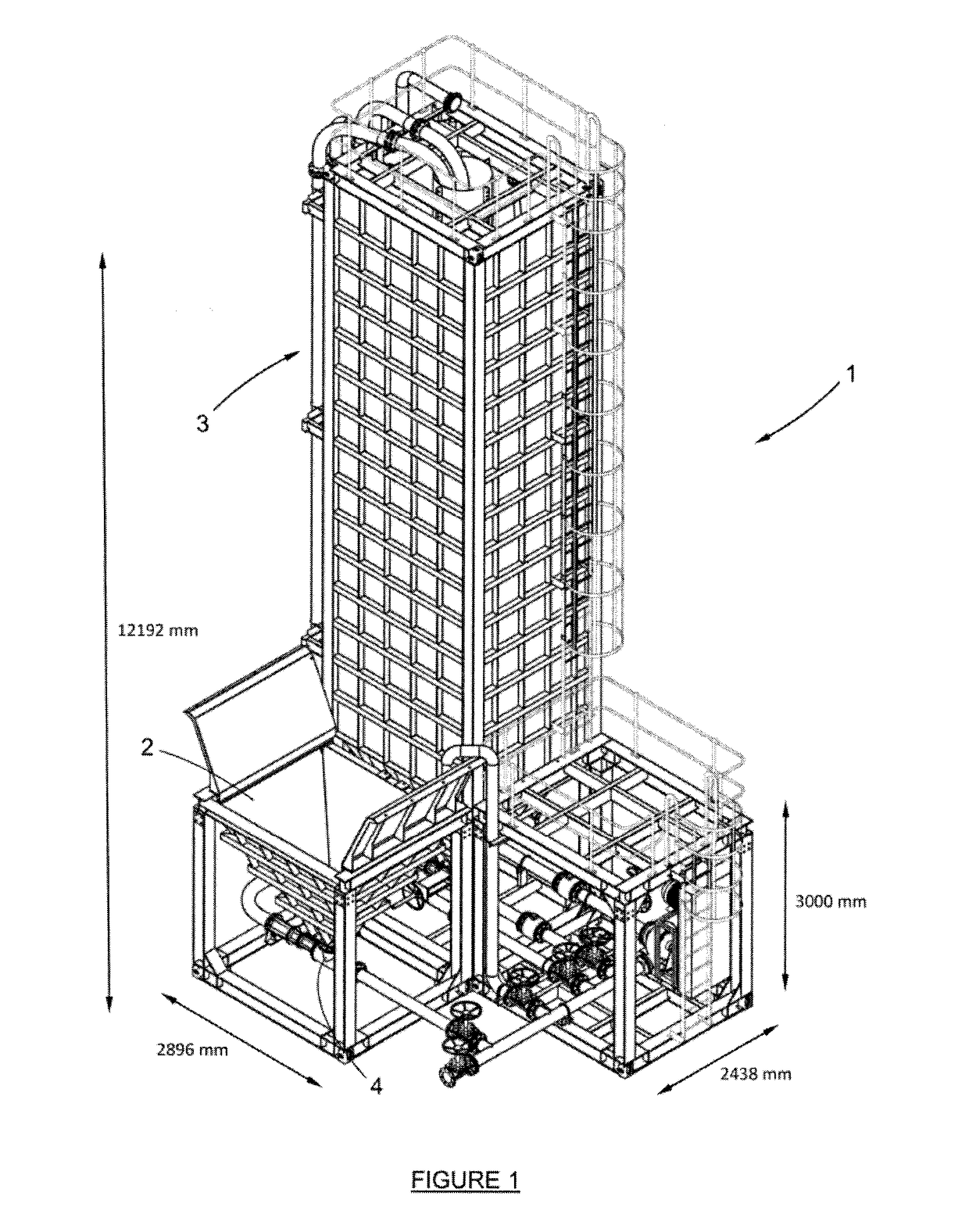

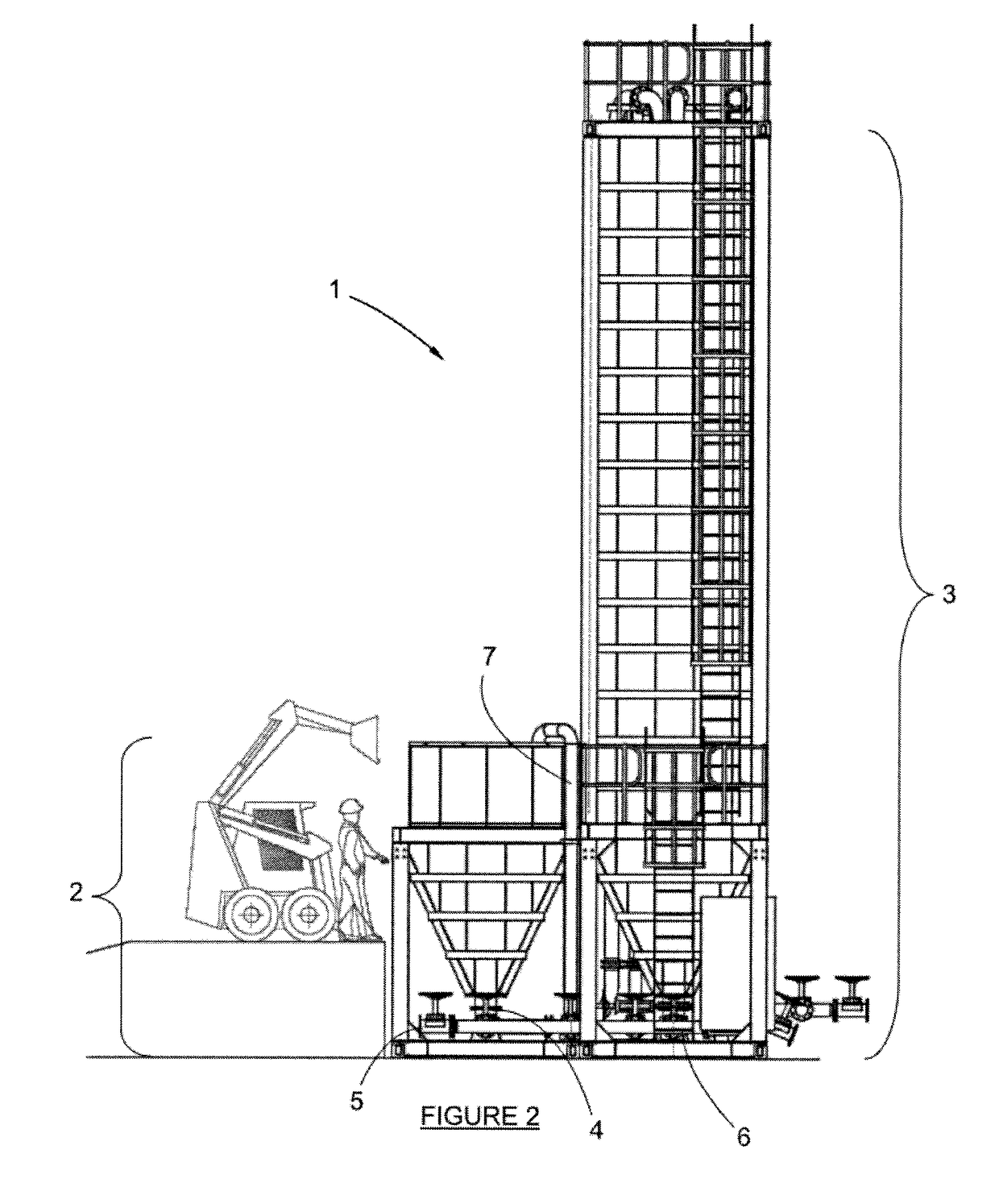

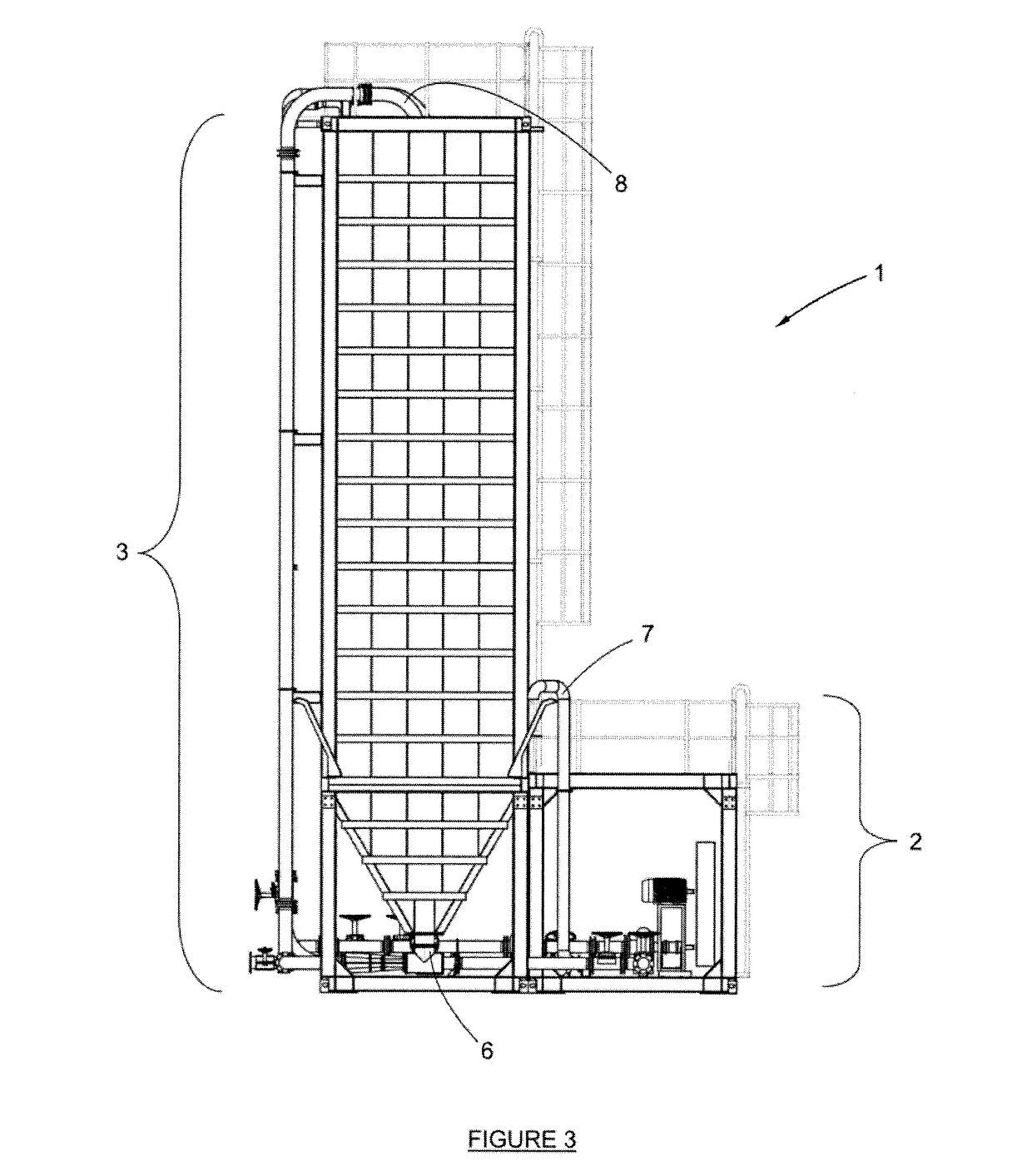

[0099]Solids or copper-rich feed material (not shown) is fed dry into a feed receptacle, in the form of a feed bin 2 of the apparatus 1. The bottom of the feed bin is equipped with a jet pump 4 which transfers the solids from the feed bin 2 to the reaction vessel, in the form of a reactor 3. The jet pump 4 produces a vacuum by means of the venturi effect. A centrifugal drive pump 5 is used as the drive pump for generating the flow through the jet pump 4. The reactor 3 is equipped with an additional jet pump 6 similar to the jet pump 4 located in feed bin 2. The jet pump 6 is capable of pumping up to 55% solids and uses either process water for start-up conditions or leach solution during the circulation process.

[0100]The reactor 3 is designed to treat a batch of 40 tons of dry feed (up to −5 mm) at a density of 50% solids. The 40 tons of feed material is loaded into the reactor 3 through the feed bin 2 and jet pump 4 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com