Vehicle-Attached Excavation Implement

a technology of excavation equipment and vehicle attachment, which is applied in the direction of mechanical machines/dredgers, soil shifting machines/dredgers, constructions, etc., can solve the problems of limited power take-off attachment for rotational power, difficult transportation and maneuvering, and dangerous and expensive transportation, etc., to achieve safe and convenient transportation, speed, efficiency and flexibility, and the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

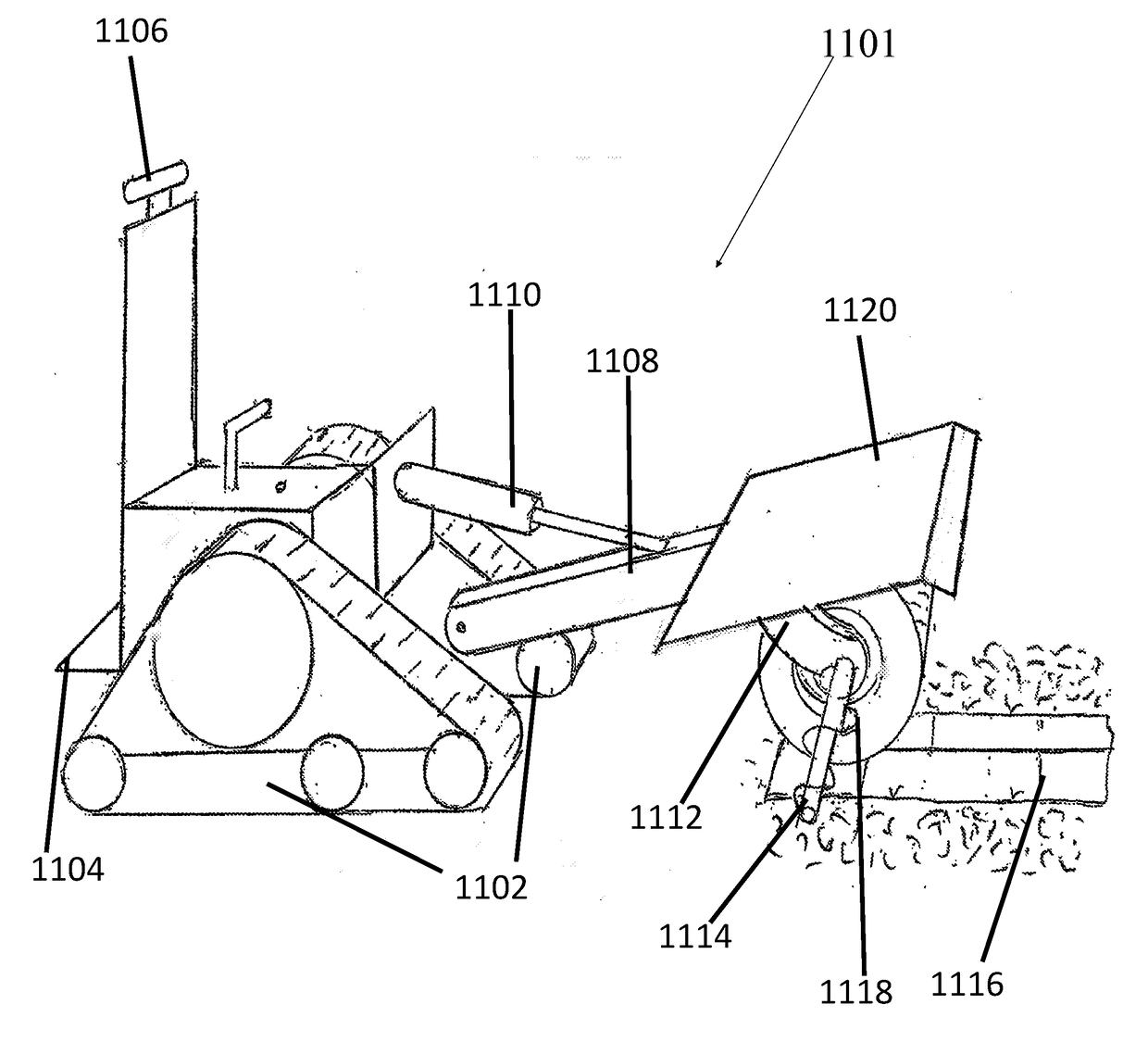

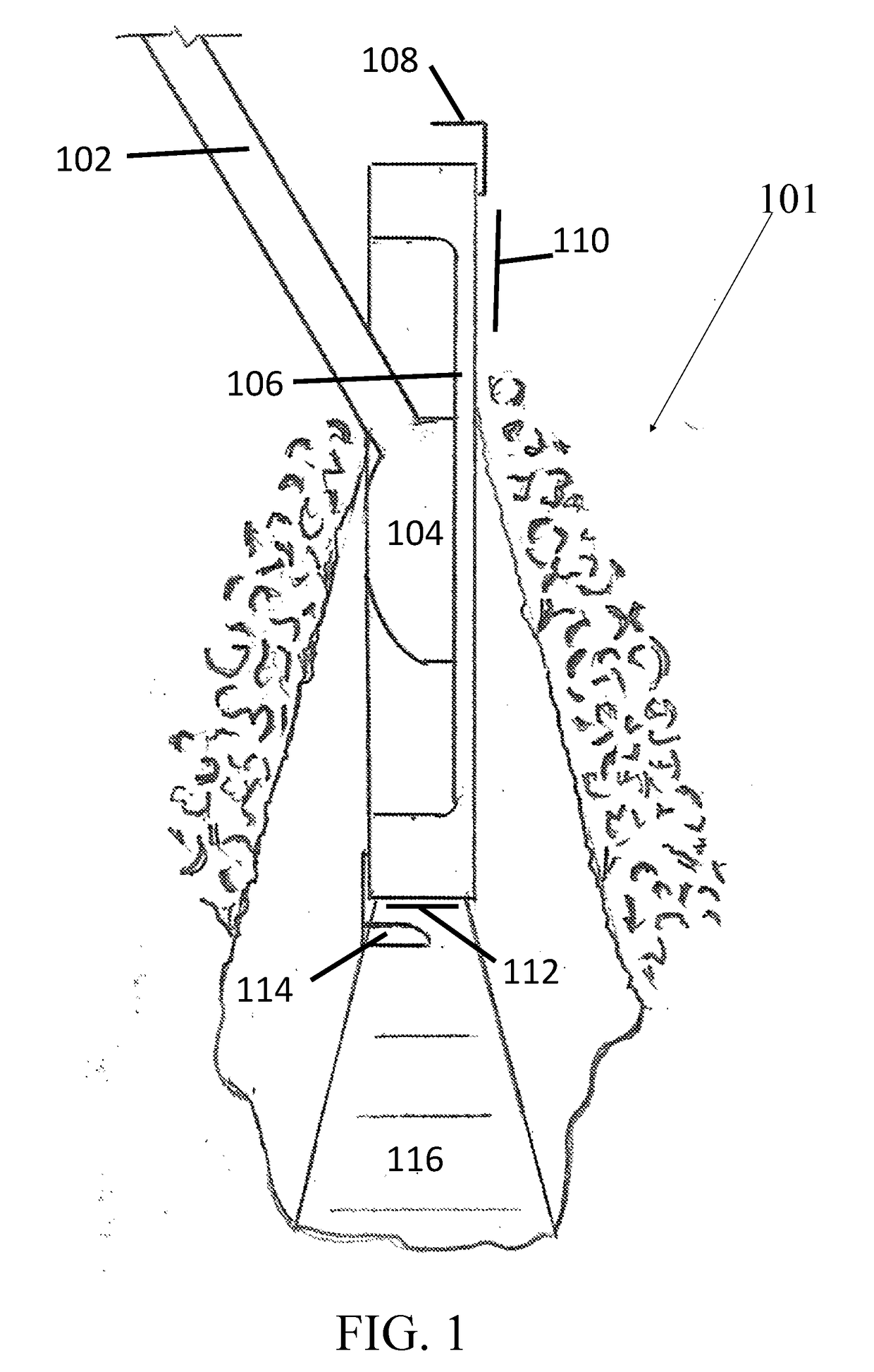

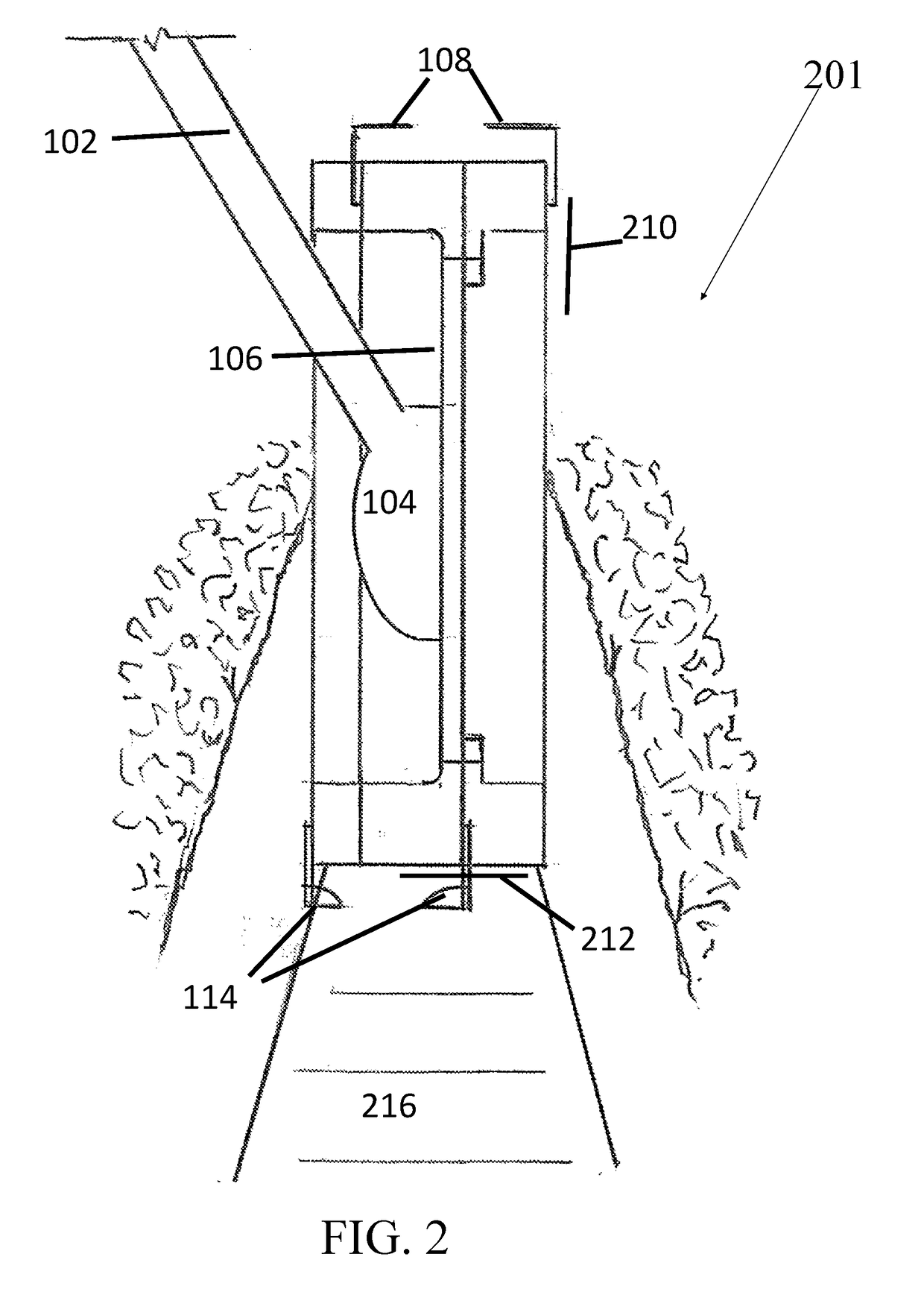

[0047]This embodiment combines vehicles from the prior art with an implement and apparatuses set forth in the previously patented Tractor Mounted Excavation Implement, and later Enhancements and Extensions to the implement. While the vehicles themselves are not claimed herein, multiple combinations are presented to show how the implement could exploit various delivery platforms. Additionally, various mechanisms providing rotational power to the apparatuses are shown, as are numerous methods of directing and maneuvering the apparatus for increased versatility.

[0048]Rather than a tractor-mounted implement, presented herein is a vehicle-attached excavating implement for multiple excavating tasks, referred to as the task-associated excavations of depressions in the earth. These interchangeable task-associated rotational excavating apparatuses can address numerous tasks including, but not limited to, forming foundation footings, ditches, trenches, landscape or gardening beds, or shallow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com