Systems and Methods Implementing Layers of Devitrified Metallic Glass-Based Materials

a technology of devitrification and glass-based materials, applied in the direction of coatings, layered products, chemistry apparatus and processes, etc., can solve the problems of limited thickness with which metallic glasses could be formed, limited viability of engineering materials, and initial largely limited limitations of metallic glasses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

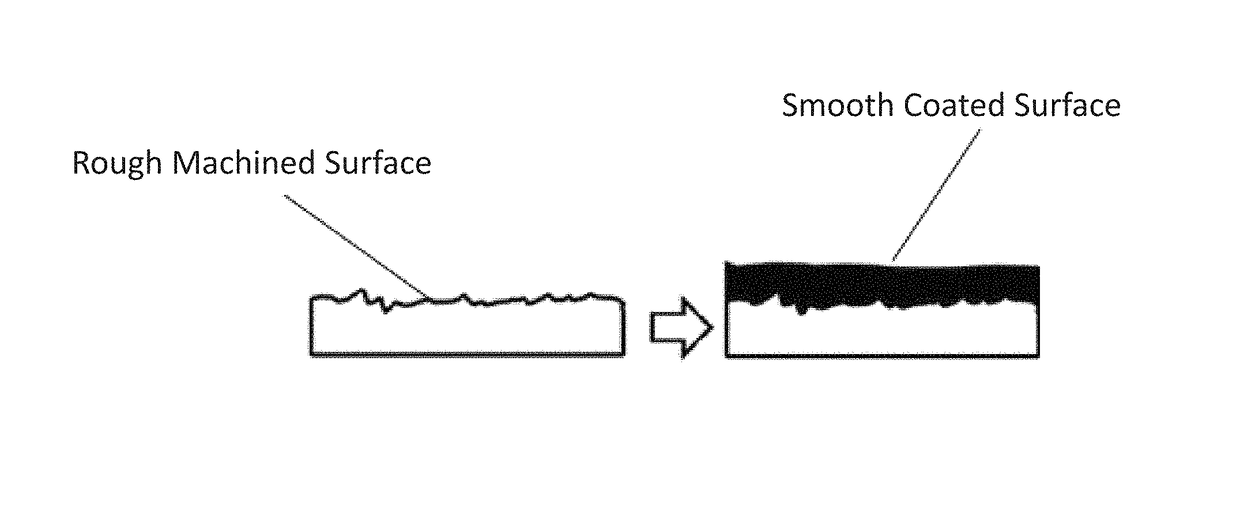

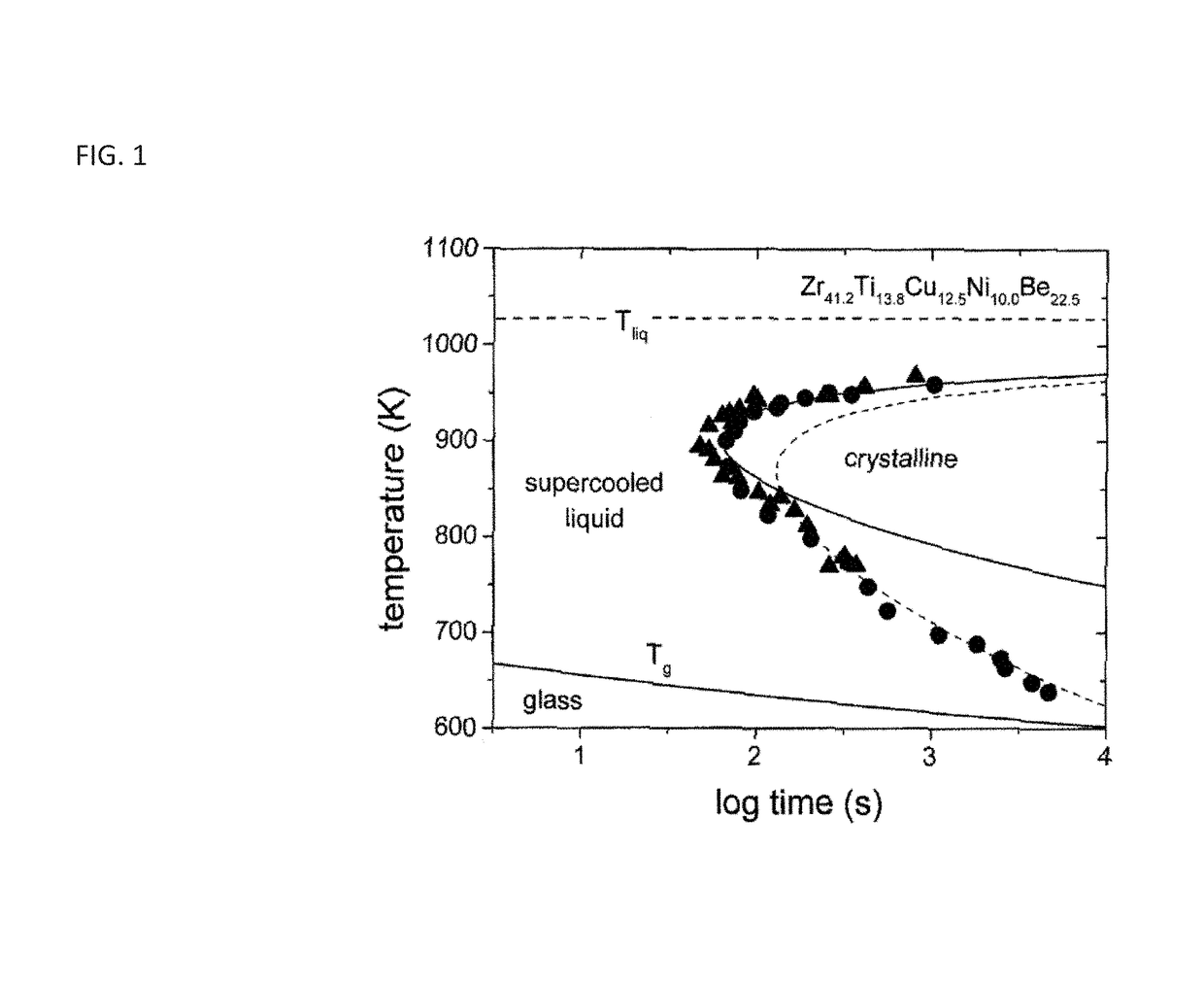

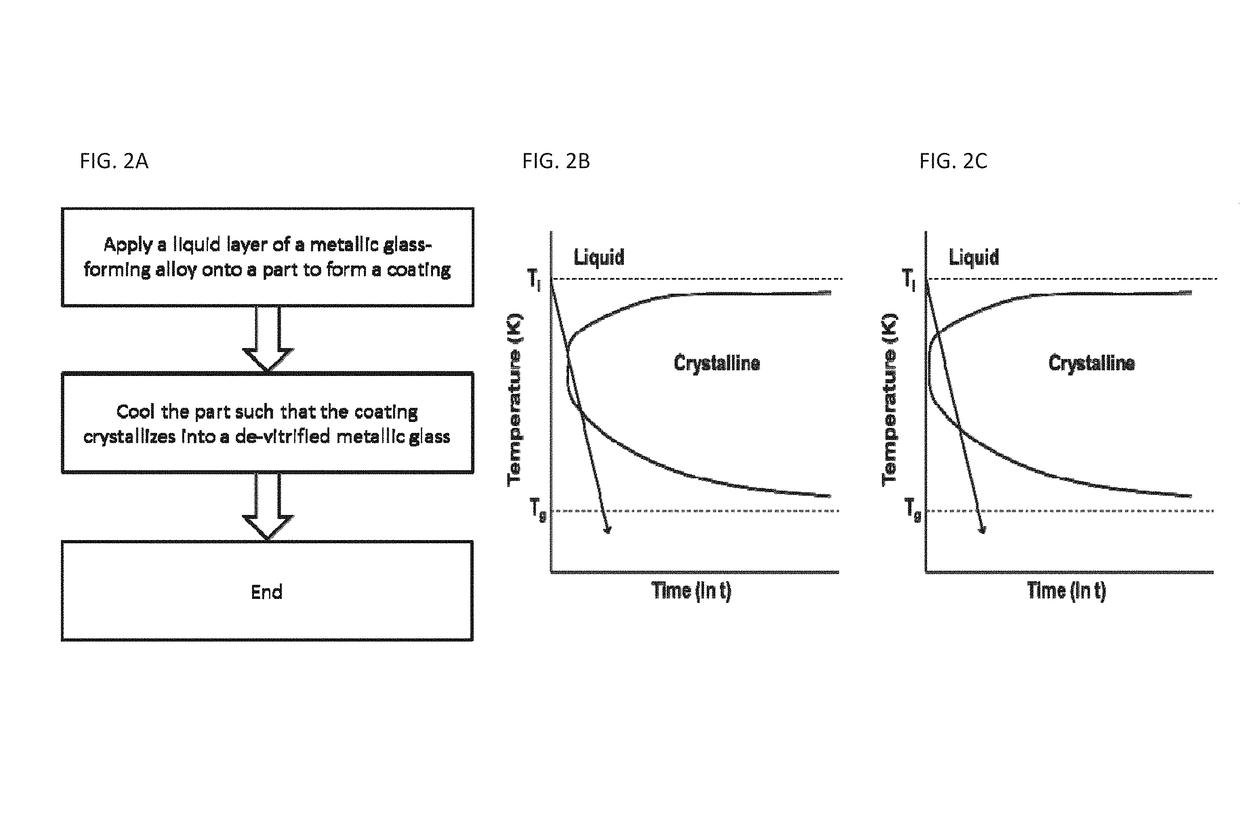

[0056]Turning now to the drawings, systems and methods for implementing layers of devitrified metallic glass-based materials are illustrated. In many embodiments the systems and methods comprise dipping an object into a molten reservoir of a metallic glass-based material to form a layer on a portion of the object, and cooling the layer of metallic glass-based material at a rate slow enough to ensure devitrification of the material.

[0057]For the purpose of this invention, amorphous metal is a multi-component metal alloy that exhibits an amorphous (non-crystalline) atomic structure. These alloys can also be called metallic glasses, as they exhibit a glass transition temperature. A de-vitrified metallic glass is one that has a fully or mostly crystalline structure either due to insufficient cooling from the liquid or from heating with the intent of crystallization. For the purposes of this patent application, the term ‘metallic glass-based material’ shall be interpreted to be inclusive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical cooling rate | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com