Centrifugal pressure booster and method for modifying or constructing a centrifugal pressure booster

a centrifugal pressure booster and centrifugal pump technology, which is applied in the direction of liquid fuel engines, electrical apparatus, dynamo-electric machines, etc., can solve the problems of restricting the rotation of the rotor, shortening the service life of the pressure booster, and restricting the maximum power rating and rotations per minute, so as to achieve the effect of enhancing the coolant flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

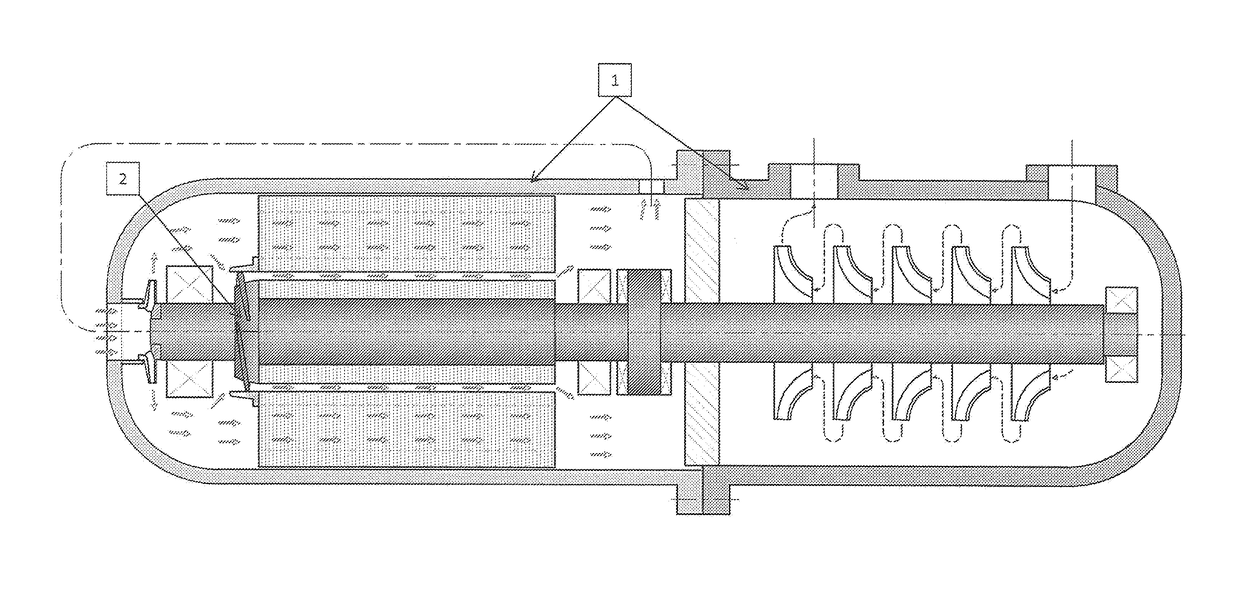

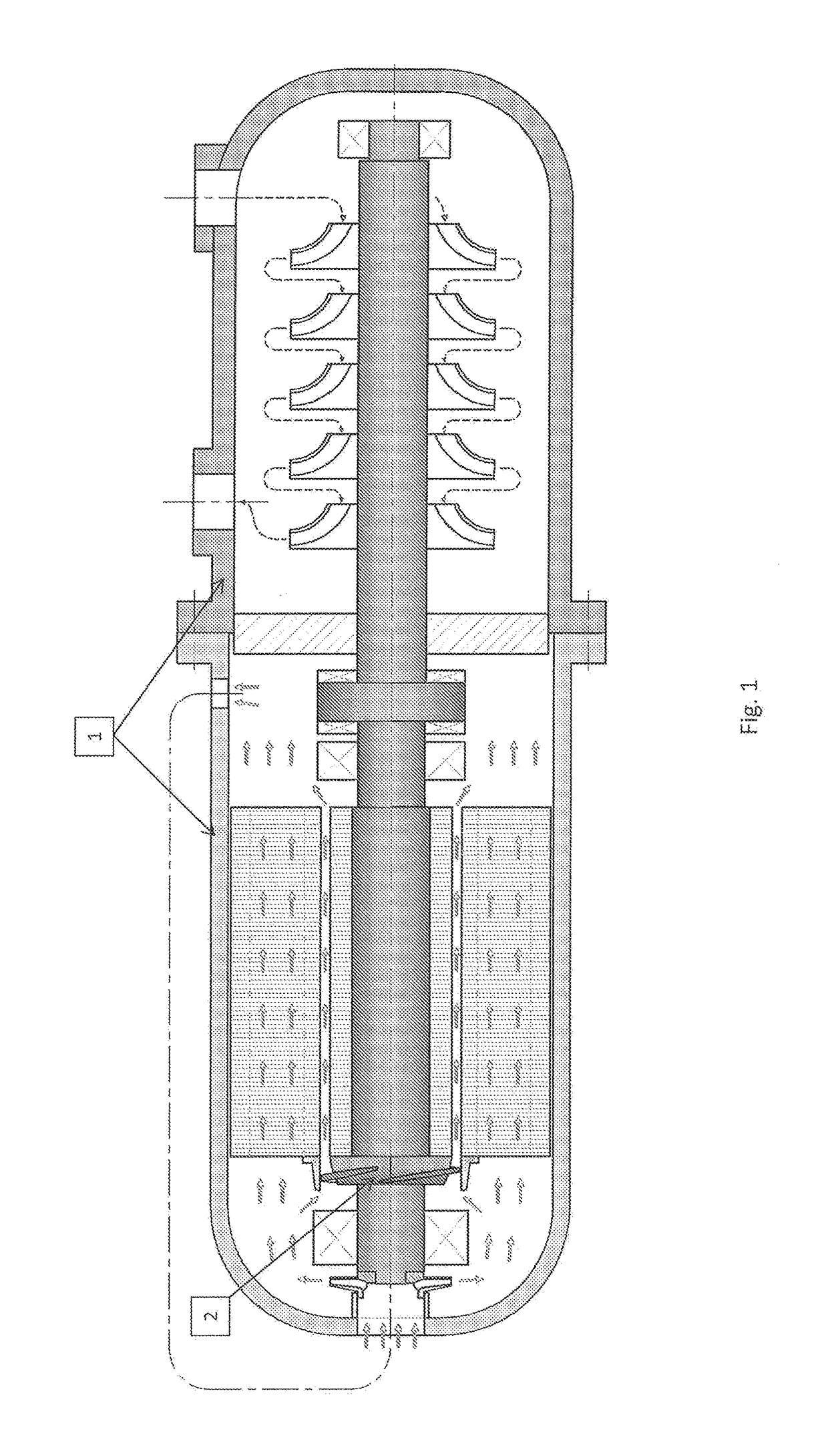

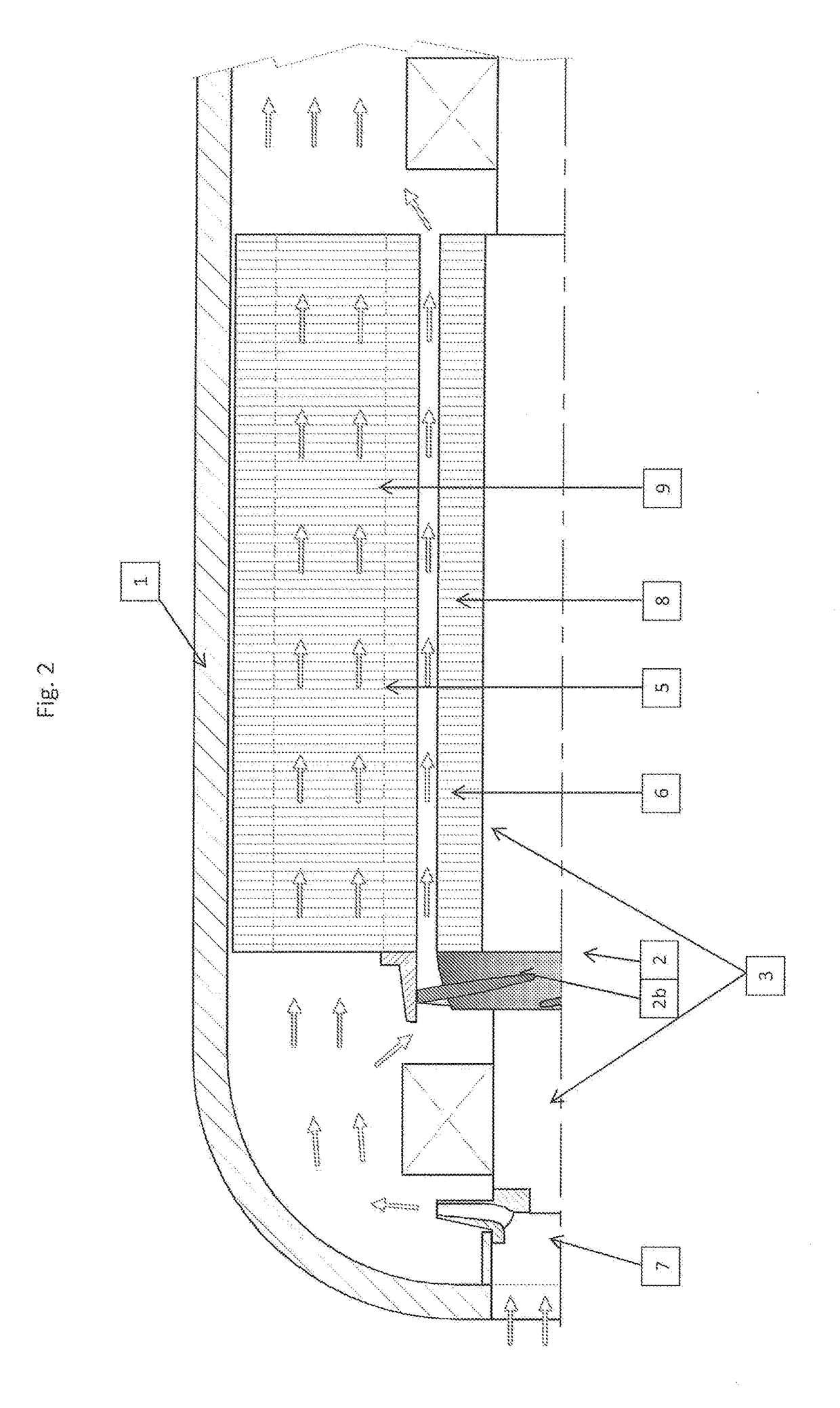

[0024]Reference is made to FIG. 1, illustrating, in longitudinal section, a subsea pressure booster 1 of the invention, with a combined balancing device and rotor stator gap circulation impeller 2. FIG. 2 illustrates the motor part of the subsea pressure booster of FIG. 1 in more detail. Accordingly, in the illustrated embodiment, the rotor stator gap coolant inlet pump is a combined impeller and balancing device. In some otherwise identical or similar embodiments, the rotor stator gap coolant inlet pump is not a combined impeller and balancing device. FIG. 2 illustrates the impeller 2 in detail, and it can be seen clearly that the impeller comprises a number of blades 2b. The impeller is fastened to the rotor 3 at the inlet of the rotor stator gap, as an axial extension of the rotor laminations / short circuit ring. The impeller has outer diameter just smaller than the outer diameter of the rotor stator gap, to ensure clearance at different temperatures. The outlet outer diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com