Composition and Method Used for Chemical Mechanical Planarization of Metals

a technology of mechanical planarization and composition, applied in the direction of lapping machines, manufacturing tools, other chemical processes, etc., can solve the problems of unsatisfactory dissolution process, non optically flat surface, undesired results on the wafer surface, etc., to facilitate the removal of metal, reduce the water content form, and contribute to undesirable polishing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

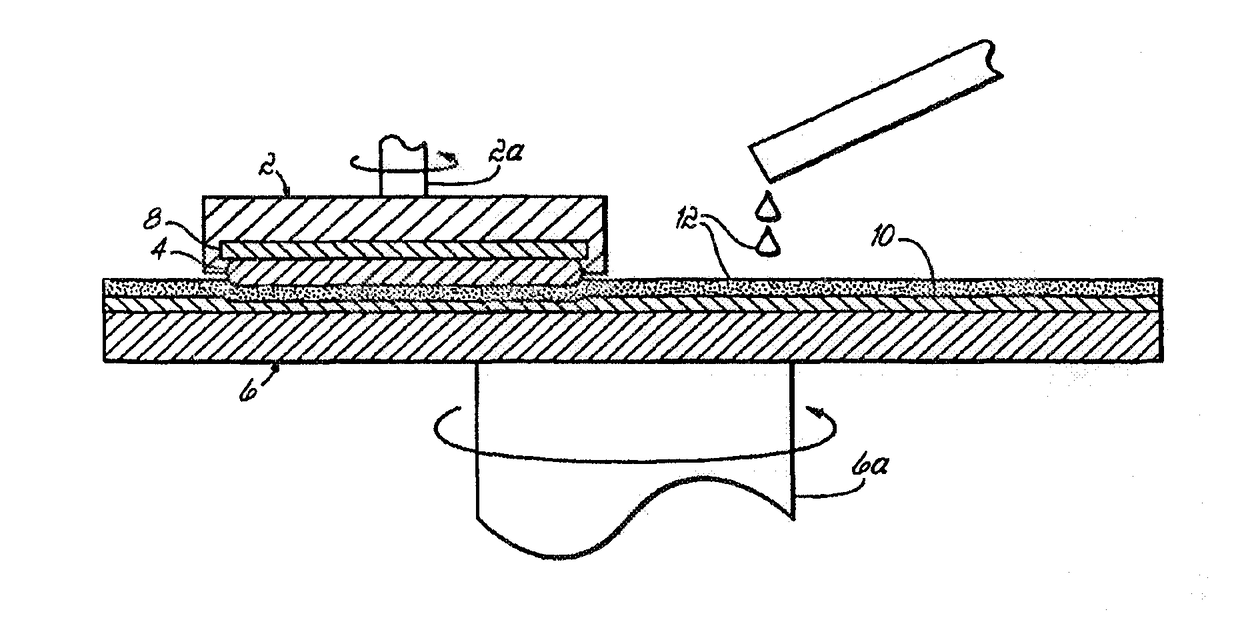

[0046]The rates of removal for several materials on a wafer surface were evaluated using several formulations. The testing apparatus was an IPEC 472 unit from SpeedFam-IPEC Corporation, Phoenix, Ariz. The 22.5 inch (57.21 cm) diameter table was fitted with a pre-stacked K-grooved IC 1000 / SBA IV polishing pad from Rode Corp., Phoenix, Ariz. 85034. The table was rotated relative to a smaller diameter rotating carrier to which the 200 mm wafer was attached. Both the table, also known as the platen, and the carrier rotated in the same direction, but at different speeds. Polishing formulation was deposited onto the polishing pad and thereby conveyed by relative movement of the rotating pad to the carrier into contact with the wafer surface.

[0047]Several sets of process parameters were utilized during the course of evaluating various formulations for their ability to remove material from the wafer surface. The process parameters can affect the copper removal rate and the parameters for ea...

example 2

[0090]The ability of different particulate substances in the composition to enhance the copper removal rate was evaluated. A single formulation composition as set out in Table 9 below was used to evaluate various particulate materials.

[0091]The individual formulas were prepared by first blending aminoacetic acid, 1,2,4-triazole and water, then adding in the specific particulate material generally in the form of a pre-dispersion or other water-containing flowable form from the manufacturer; or alternatively directly from the powder or as a homogeneous laboratory-prepared mixture of powder and water optionally containing small amounts of stabilizing additive.

TABLE 9ComponentConcentrationH2O21%Aminoacetic Acid1%1,2,4-Triazole500 ppmParticulate Material0.1% Deionized WaterBalance

[0092]Various formulations were developed by substituting different particles and evaluating the rates of removal. The CMP protocol described in Example 1 (OP-I) was utilized for a one minute run time for formul...

example 3

[0105]The use of other amino acids in addition to aminoacetic acid was evaluated. Various formulations containing components identical but for the amino acid were prepared, having a base composition as ‘shown below in Table 11. The colloidal silica was the same as that described previously in Example 1. The test solutions were prepared by dissolving the desired amount of amino acid and 1,2,4-triazole in deionized water in an open container. To this solution was added the colloidal silica. The solution containing the colloidal silica was homogenized by physical agitation using a stirring rod for several minutes before adding H2O2 as the oxidizer.

TABLE 11ComponentConcentrationH2O21%Amino Acid2%1,2,4-Triazole500 ppmColloidal SiO20.1% Deionized WaterBalance

[0106]The formulation numbers and particular amino acids used in each of the formulations are listed below in Table 12. Table 12 lists the formula number, the particular amino acid used and the rate of removal of the copper for a one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| formulation | aaaaa | aaaaa |

| formulation | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com