Furniture system having a linear actuator

a technology of linear actuators and actuators, which is applied in the direction of adjustable height tables, chairs, and gear mechanisms, can solve the problems of large increase in the production cost of linear actuators, meshing errors, and noise development of gear mechanisms, and achieves low noise generation and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

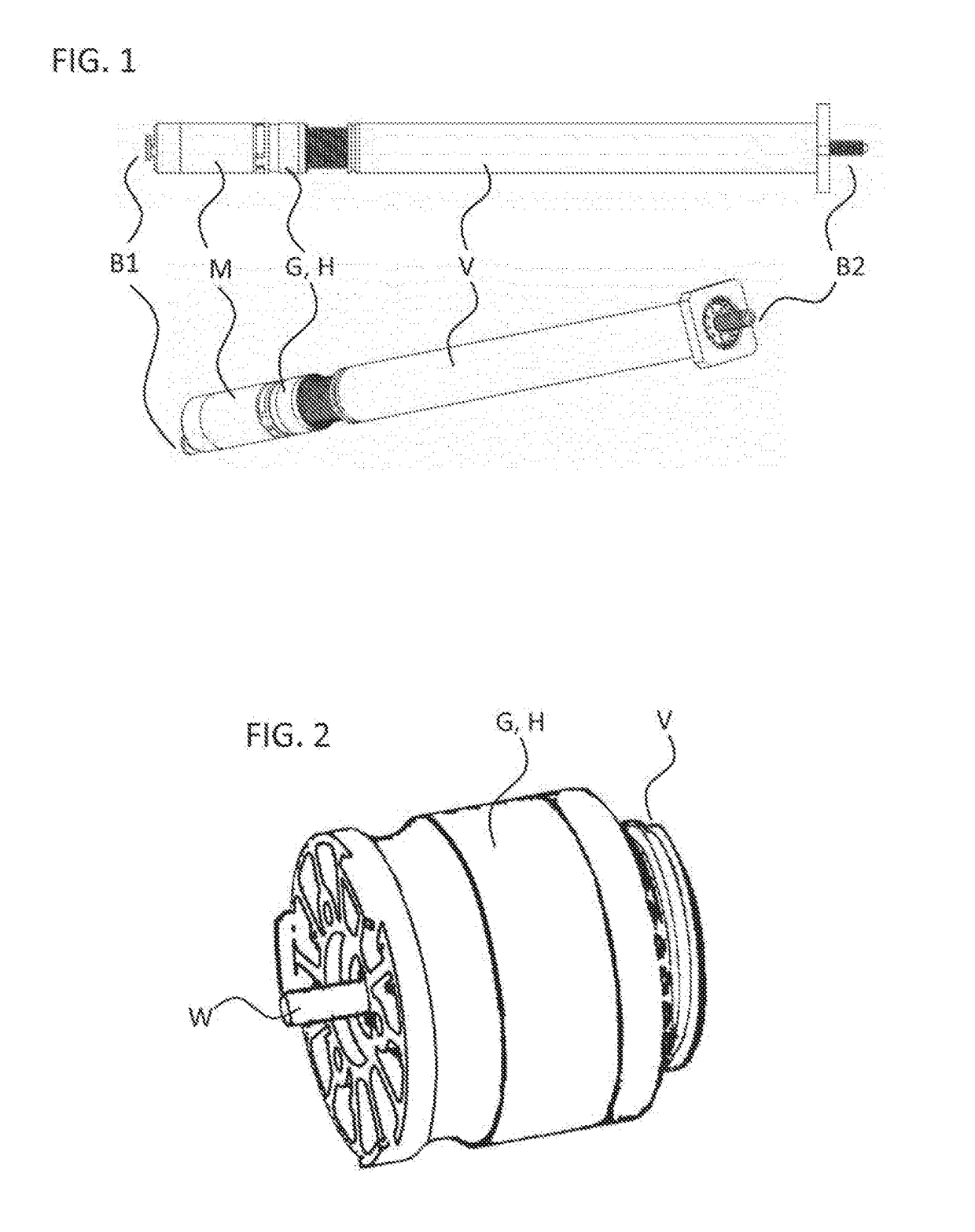

[0055]FIG. 1 shows an example of an embodiment of a linear actuator according to the improved concept. The upper part of FIG. 1 shows a side view of the linear actuator, whereas the lower part of FIG. 1 shows a perspective view of this linear actuator.

[0056]The linear actuator includes a gear mechanism G, a motor M, which is coupled to the gear mechanism G on the drive side, as well as an adjustment member V connected to the gear mechanism G on the output side. The linear actuator further comprises a first fastening element B1 fixed to the motor M and a second fastening member B2 fixed to the adjustment member V.

[0057]The adjustment member V includes a telescopic spindle. Exemplary embodiments of the adjustment member V are shown in documents DE 10 2012 102 298 A1 as well as DE 10 2012 013 979 A1, the disclosures of which are incorporated in their entirety into the present document by reference.

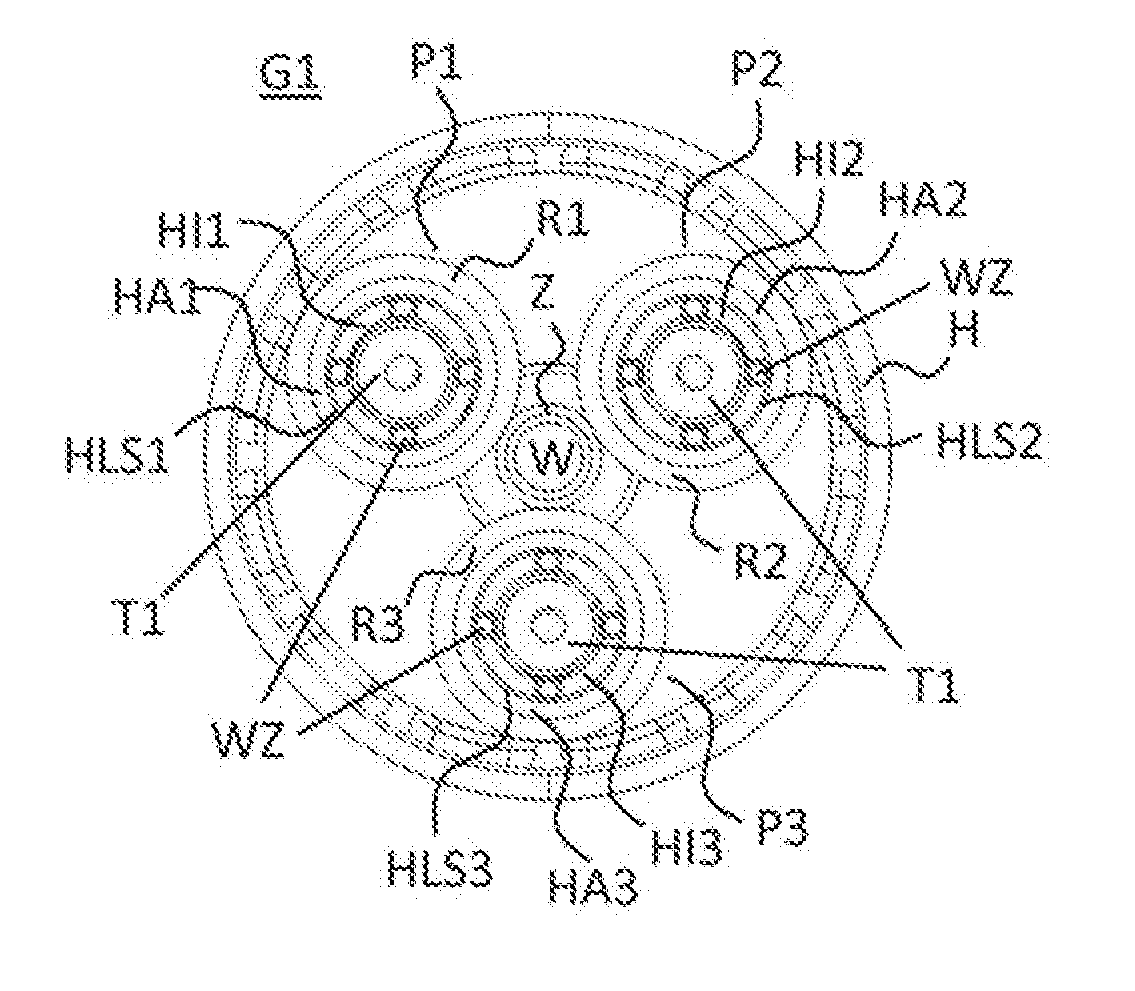

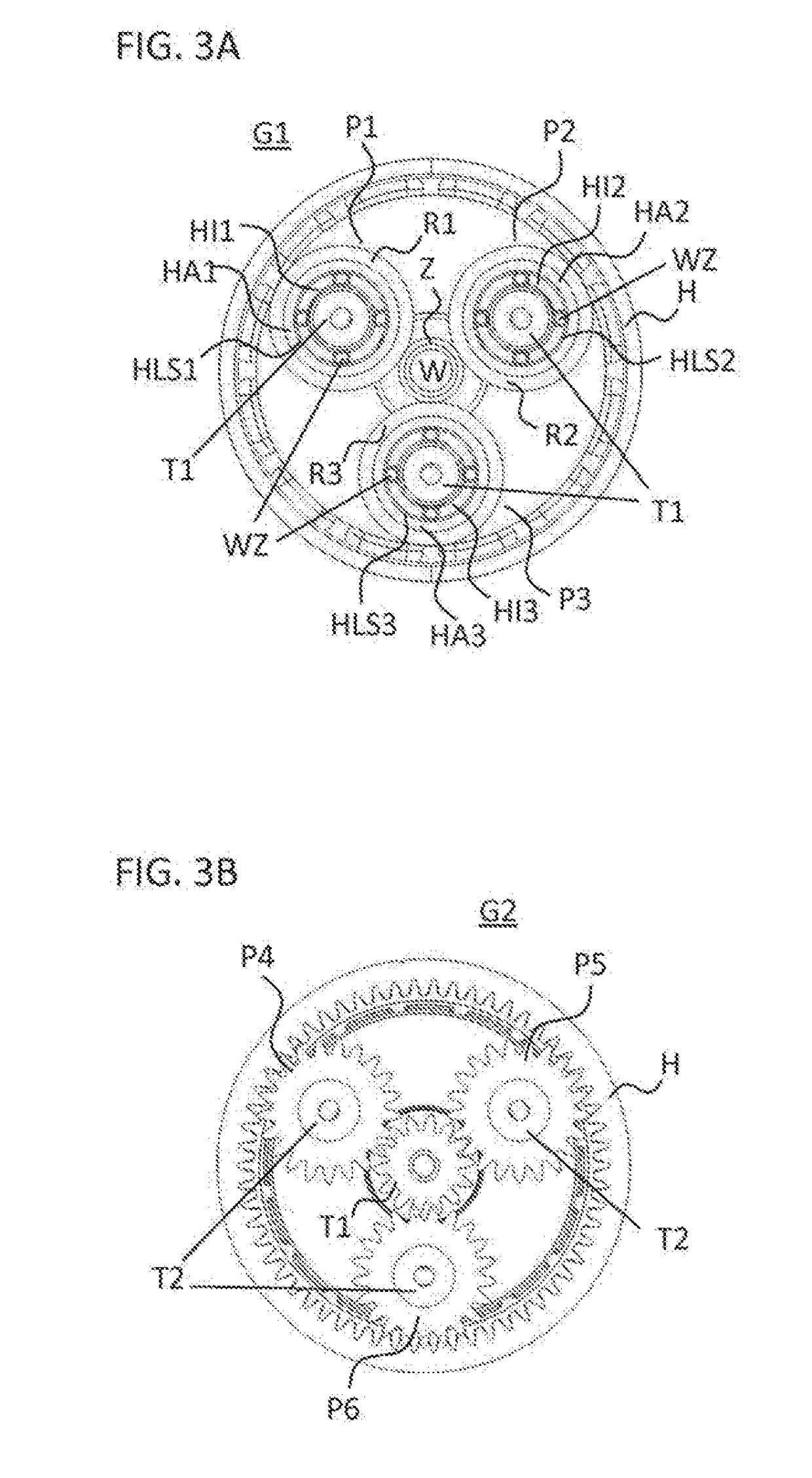

[0058]In the illustrated embodiment of the linear actuator, the gear mechanism G includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com