Lubricant additive composition, lubricating composition containing same and engine oil composition consisting of lubricating composition

a technology of additive composition and additive composition, which is applied in the field of additive composition, lubricating composition, and engine oil composition consisting of lubricating composition, can solve the problems of limited friction reduction effect of only increasing the amount of organic molybdenum compounds, high amount of amine compounds, and high amount of organic compounds, so as to achieve significant prevention of corrosion of copper and copper alloys, the effect of friction reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0068]The present invention is hereinafter more specifically described by way of the Examples. In the Examples, “%” is based on the mass unless otherwise stated.

[0069]With the following compounds and base oils, lubricating compositions of Examples 1 to 10 and Comparative Examples 1 to 5 having the compositions indicated in Table 1 were prepared. The values of the compositions indicated in the table are in parts by mass of compounds when the whole amount of the lubricating composition is regarded as 100 parts by mass.

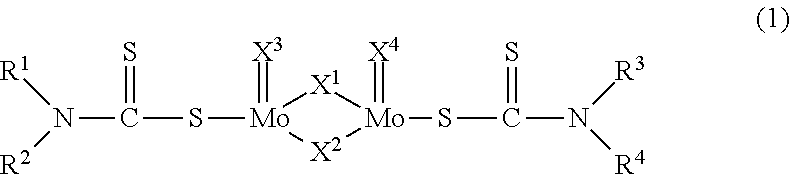

[0070](A1) Compound of general formula (1), wherein R1 and R2 are respectively a 2-ethylhexyl group, R3 and R4 are respectively a branched tridecyl group, X1 and X2 are respectively a sulphur atom and X3 and X4 are respectively an oxygen atom (Mo content: 18.1%)[0071](A2) Compound of general formula (1), wherein R4 to R4 are respectively a 2-ethylhexyl group, X4 and X2 are respectively a sulphur atom and X3 and X4 are respectively an oxygen atom (Mo content: 20.7%)[0072]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com