Eggoist multi-level system of floor equipment for commercial poultry maintenance

a multi-level, floor technology, applied in the field of poultry maintenance equipment, can solve the problems of reducing the ability of birds to move, affecting the quality of life of birds, increasing morbidity, etc., and achieves the effect of reducing the risk of bird injury, reducing the probability of birds infecting, and reducing the use of the overall level area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

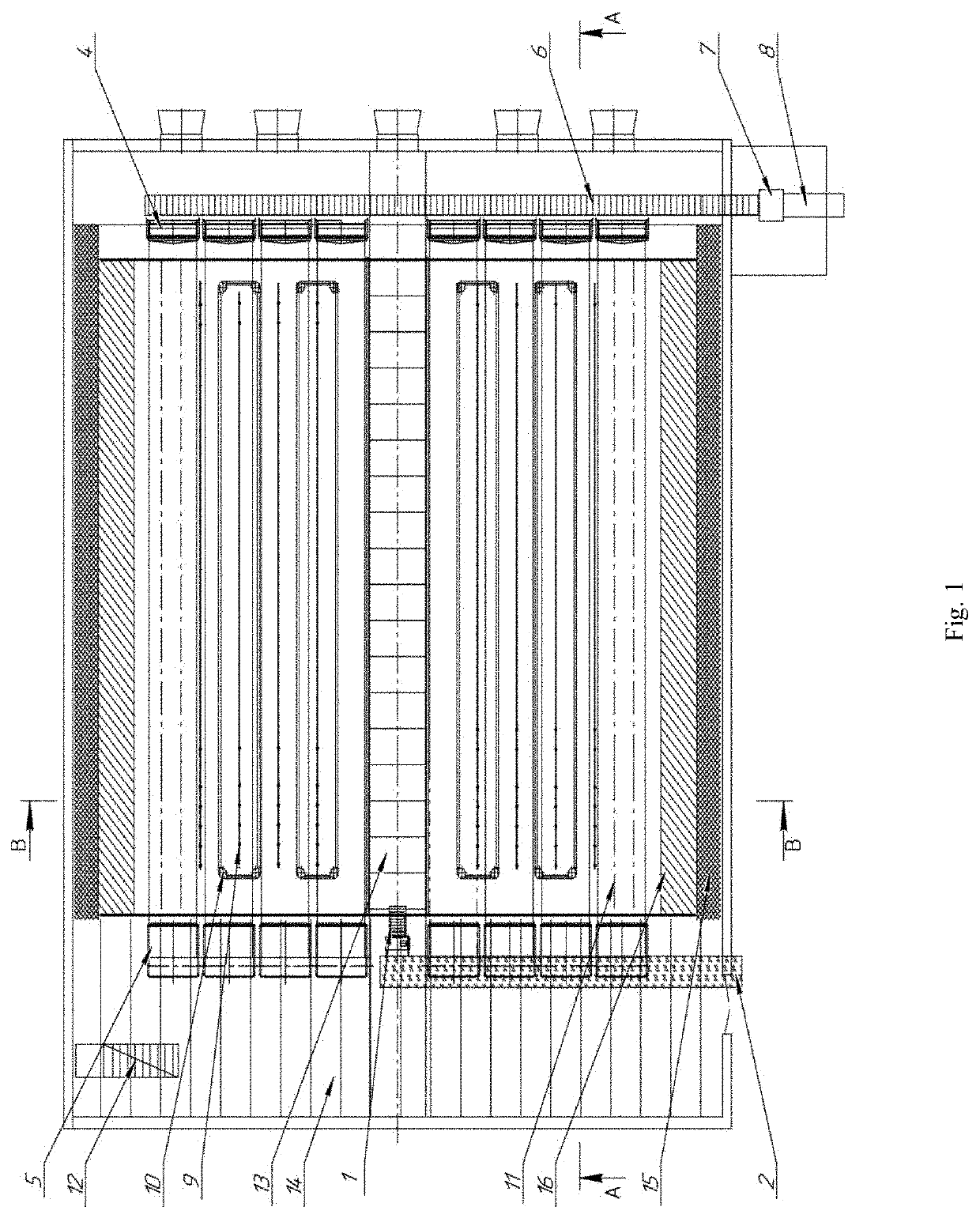

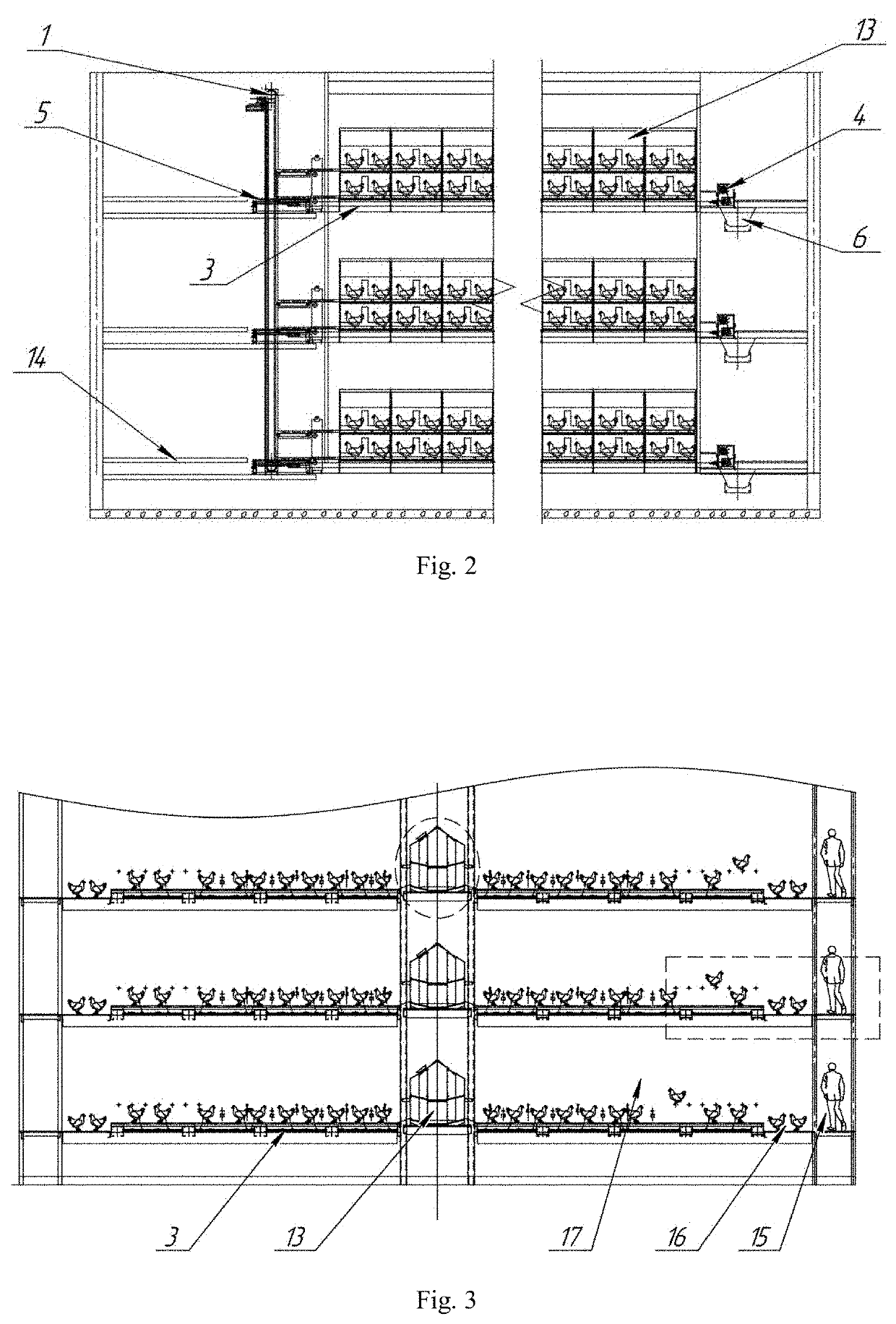

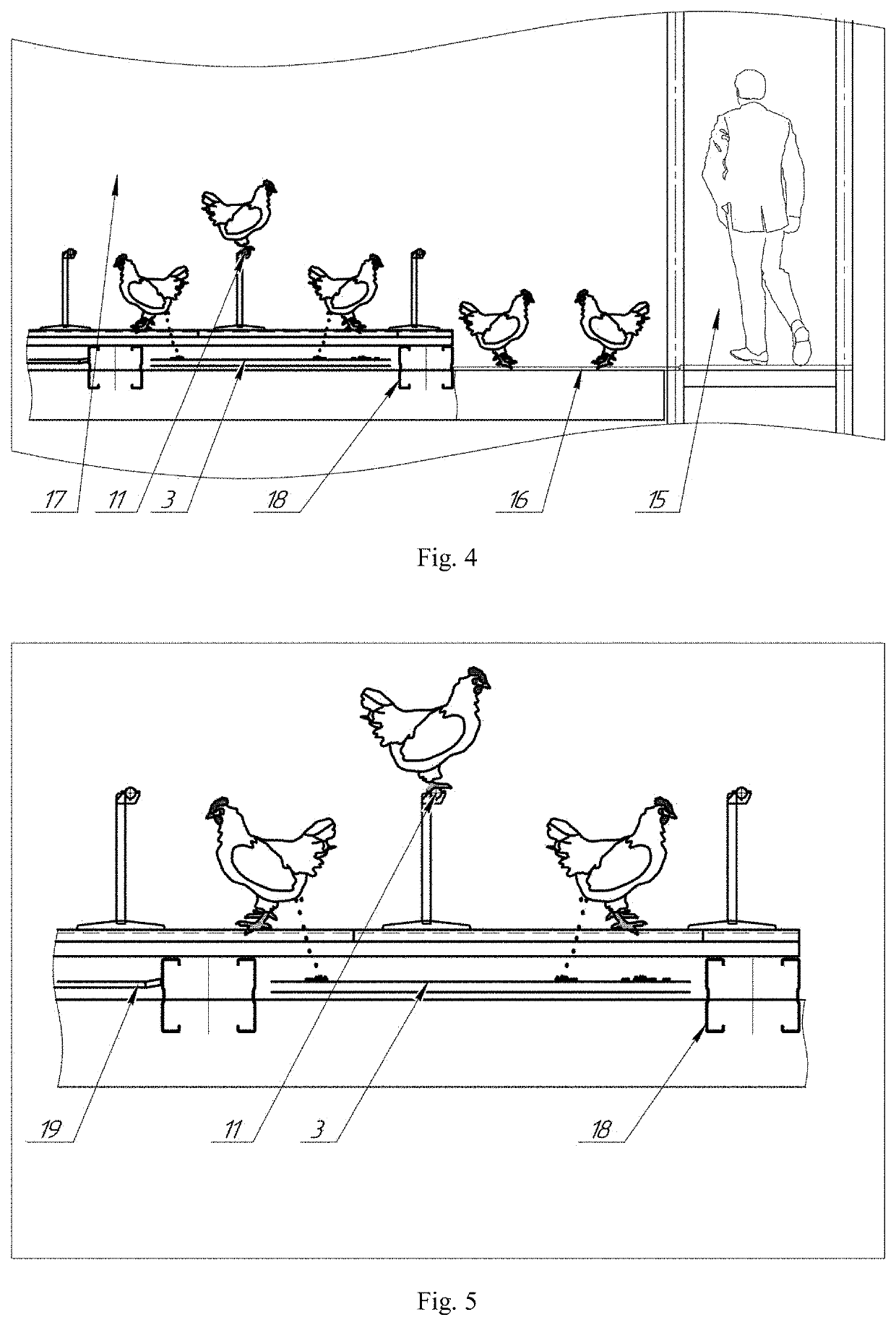

[0040]All the levels in the aviary fitted with EGGOIST equipment system are the same, apart from the bottom level, where extra production equipment is installed. The level where the life cycle of laying hens takes place represents an aviary with guards and a mesh floor. The arrangement of a separate level is illustrated in FIG. 1. The elevator 1 accumulates and collects all the eggs laid by the hens in the nests located within one level and further passes them to the cross collecting transporter 2 positioned at the first level in the frontal part of the aviary construction and intended for transporting the eggs outside the aviary for further processing, grading and packing. The manure removal transporter belt 3 (designated on FIG. 2 and FIG. 3) runs along the whole level. The belt 3 is positioned in several longitudinal rows, spanning the whole level on a certain distance below the level of the wire mesh floor, and is operated by a motor-drive manure removal station 4, which is posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com